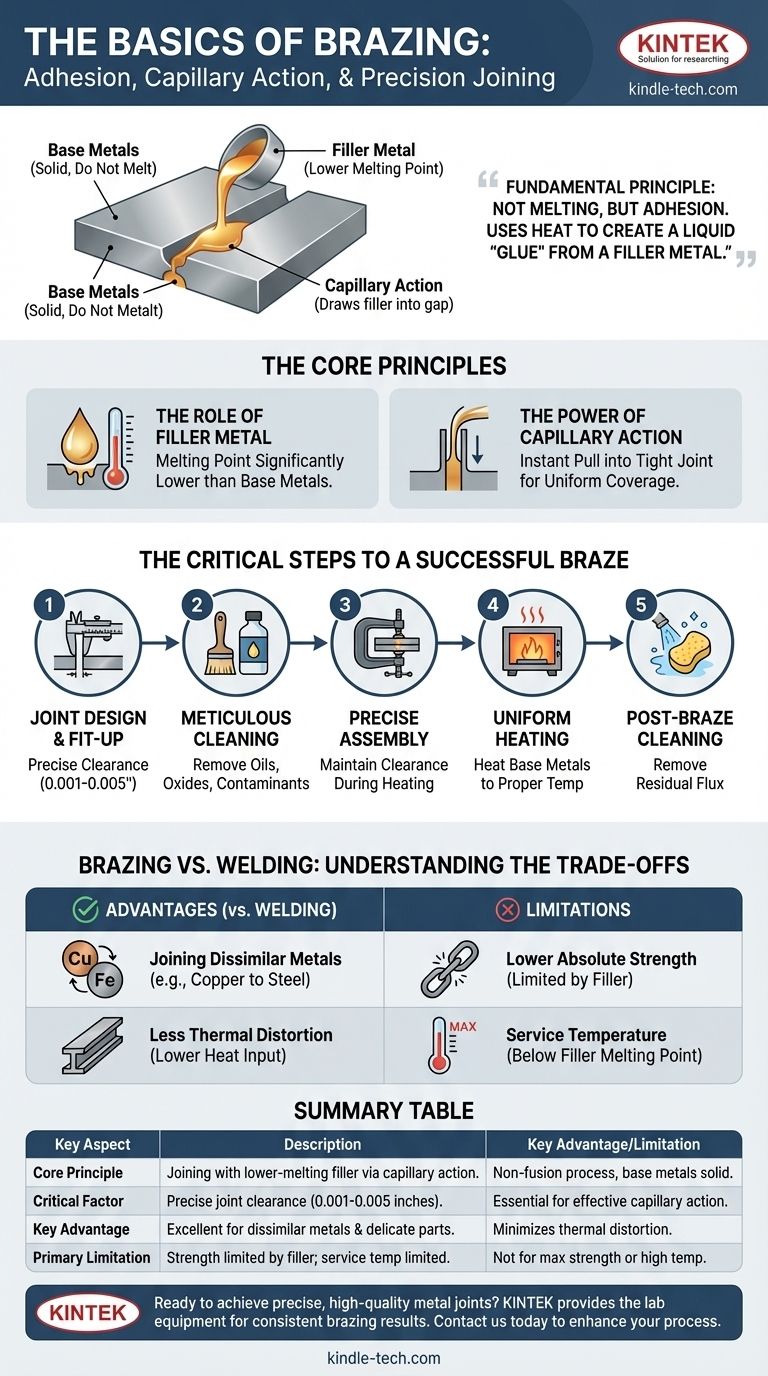

At its core, brazing is a metal-joining process where a filler metal is heated above its melting point and distributed between two or more close-fitting parts. The filler metal, which has a lower melting point than the base metals, is drawn into the gap via capillary action. This creates a strong metallurgical bond as the filler cools and solidifies, all without melting the base metals themselves.

The fundamental principle of brazing is not melting, but adhesion. It uses heat to create a liquid "glue" from a filler metal that is then pulled into a tight joint by capillary action, forming a bond that is often stronger than the filler metal itself.

The Core Principle: How Brazing Works

To truly understand brazing, you must look beyond the simple act of heating. The process relies on a precise interplay of temperature, material science, and physics.

The Role of the Filler Metal

The entire process is enabled by a filler metal (also called a brazing alloy) with a melting point that is significantly lower than that of the parts being joined.

This allows the assembly to be heated to a temperature that is hot enough to melt the filler, but not hot enough to damage or melt the base components.

The Power of Capillary Action

Capillary action is the critical force that makes brazing work. It is the tendency of a liquid to be drawn into a narrow space, even against the force of gravity.

For brazing to succeed, the gap between the two parts must be carefully controlled. When the molten filler metal touches this narrow gap, it is instantly pulled through the entire joint area, ensuring complete and uniform coverage.

Why the Base Metals Don't Melt

This is the key distinction between brazing and welding. In welding, the edges of the base metals are melted to fuse them together.

In brazing, the base metals remain solid. The heat serves only one purpose: to bring the assembly up to a temperature that will melt the filler metal and facilitate the bond. This lower heat input results in less thermal stress and distortion.

The Critical Steps to a Successful Braze

A reliable brazed joint is the result of a disciplined, step-by-step process. Each stage is essential for creating the conditions necessary for a strong bond.

Step 1: Joint Design and Fit-Up

Success begins with the design. The space between the parts, known as the joint clearance, must be extremely precise.

If the gap is too wide, capillary action will fail. If it is too narrow, the filler metal cannot flow into the joint. A typical clearance is between 0.001 and 0.005 inches (0.025-0.127 mm).

Step 2: Meticulous Cleaning

The surfaces of the joint must be immaculately clean. Any contaminants—such as oils, grease, or oxides (rust)—will prevent the molten filler from properly "wetting" and bonding to the base metals.

Cleaning is typically done mechanically (with abrasive pads or wire brushes) and/or chemically (with solvents and acid pickles).

Step 3: Precise Assembly and Fixturing

Once clean, the parts must be assembled and held firmly in place. Fixtures or clamps are used to maintain the critical joint clearance during the entire heating and cooling cycle.

This prevents parts from shifting as they expand and contract with temperature changes, which would compromise the joint.

Step 4: Uniform Heating and Filler Flow

The assembly is heated uniformly in a controlled environment, such as a furnace. The goal is to heat the base metals to the proper temperature.

The filler metal is then brought into contact with the hot joint, where it melts instantly and is drawn in by capillary action. You heat the part, not the filler. This ensures the filler flows toward the heat source, completely filling the joint.

Step 5: Post-Braze Cleaning

After the assembly has cooled, a final cleaning step may be required. This is primarily to remove any residual flux—a chemical agent used to prevent oxidation during heating—as it can be corrosive if left on the part.

Understanding the Trade-offs: Brazing vs. Welding

Brazing is not a universal replacement for welding; it is a distinct process with its own set of advantages and limitations. Understanding these trade-offs is key to choosing the right method for your application.

Advantage: Joining Dissimilar Metals

Because the base metals are not melted, brazing is exceptionally effective at joining different types of metals, such as copper to steel or aluminum to copper. This is very difficult or impossible to achieve with traditional welding.

Advantage: Less Thermal Distortion

The lower process temperatures used in brazing (compared to welding) impart far less heat and stress into the assembly. This makes it ideal for joining thin-walled tubes or delicate components where warping must be avoided.

Limitation: Lower Absolute Strength

While a properly made brazed joint is very strong, its ultimate strength is determined by the filler metal, which is generally not as strong as the base metals. A full-penetration weld, which fuses the base metals, typically creates a stronger overall joint.

Limitation: Service Temperature

A brazed component cannot be used in an environment where temperatures approach the melting point of the filler metal. The joint would soften and fail.

Making the Right Choice for Your Goal

Selecting the correct joining process depends entirely on your project's specific requirements for strength, material compatibility, and precision.

- If your primary focus is joining dissimilar metals: Brazing is almost always the superior choice due to its non-fusion process.

- If your primary focus is maintaining tight tolerances and minimizing part distortion: The lower heat input of brazing offers a significant advantage over welding.

- If your primary focus is maximum joint strength for a high-stress structural part: A properly designed weld is often the more robust solution.

- If your primary focus is automating a high-volume production process: Furnace brazing is highly repeatable and can process many parts at once, making it extremely efficient.

By mastering these fundamentals, you can leverage brazing to create strong, clean, and precise joints for a wide range of engineering applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Joining metals using a filler metal that melts at a lower temperature than the base metals, drawn into the joint by capillary action. |

| Critical Factor | Precise joint clearance (typically 0.001-0.005 inches) is essential for capillary action to work effectively. |

| Key Advantage | Excellent for joining dissimilar metals and minimizing thermal distortion in delicate parts. |

| Primary Limitation | Joint strength is limited by the filler metal, and service temperature cannot exceed the filler's melting point. |

Ready to achieve precise, high-quality metal joints with brazing?

The principles of brazing rely on controlled, uniform heating for success. KINTEK specializes in the lab equipment and consumables that make this possible, providing the reliable heating solutions and expert support your laboratory needs for consistent brazing results.

Contact us today to discuss how our products can enhance your brazing processes and improve your project outcomes.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the role of a laboratory ultra-low temperature freezer in stainless steel corrosion studies? Ensure Data Integrity

- What are the catalysts for catalytic pyrolysis? Unlock the Key to Optimizing Biofuel and Chemical Yields

- What materials can be applied using sputtering and what forms can the coatings take? Versatile Coating Solutions

- How to do magnetron sputtering? A Step-by-Step Guide to Thin Film Deposition

- What are the characteristics of lab grown diamonds? A Guide to Their Identity, Value, and Ethics

- What are the key issues in the synthesis of nanomaterials? Overcoming Size, Shape, and Purity Control Challenges

- What are the pros and cons of laser sintering? Unlock Complex, Functional Parts

- Why is a magnetic stirrer considered essential during PdLa/ATO catalyst preparation? Ensure Uniform Particle Dispersion