The core benefit of induction heating is its ability to generate rapid, precise, and clean heat directly inside an object without any physical contact. Unlike traditional furnaces or flames that heat surfaces from the outside-in, induction uses an electromagnetic field to make the material heat itself. This fundamental difference results in unmatched speed, superior energy efficiency, and a cleaner process.

The central concept to grasp is that induction heating is not about applying external heat. It is a non-contact process that uses electromagnetic principles to generate heat within the material, leading to faster, cleaner, and more controllable results than conventional methods.

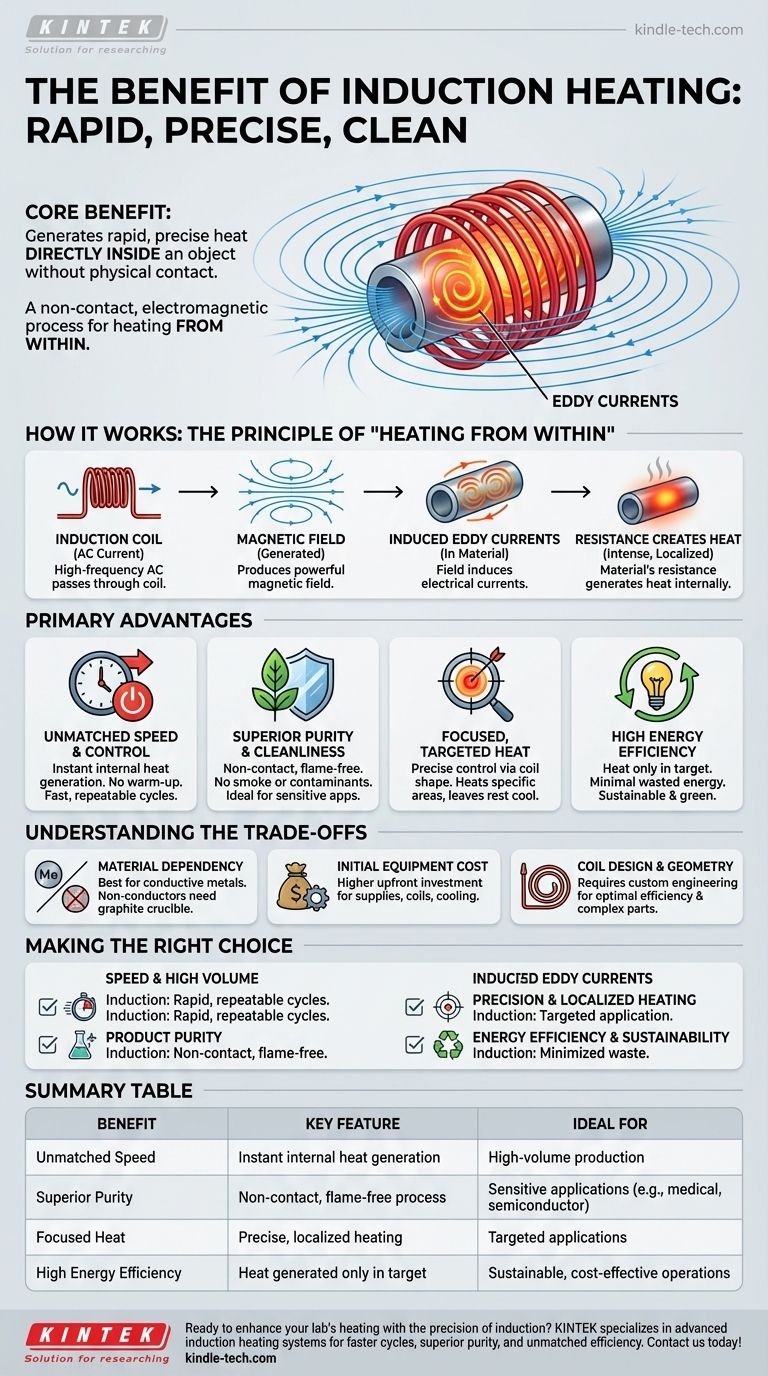

How Induction Heating Works: The Principle of "Heating from Within"

Understanding the mechanism of induction heating is key to appreciating its unique advantages. The process relies on fundamental principles of electromagnetism.

The Role of the Induction Coil

It all begins with a specially designed coil, often made of copper tubing. A high-frequency alternating current (AC) is passed through this coil.

Generating a Magnetic Field

According to the laws of physics, this alternating current produces a dynamic and powerful magnetic field in the space around and within the coil.

Inducing Internal Currents

When a conductive material, such as a metal part, is placed within this magnetic field, the field induces electrical currents inside the part itself. These are known as eddy currents.

Resistance Creates Heat

The material's natural resistance to the flow of these eddy currents generates intense, localized heat. In effect, the workpiece becomes its own heating element, allowing for incredibly rapid and precise temperature increases.

The Primary Advantages Explained

This unique "heating from within" mechanism is the source of all of induction's primary benefits over other methods like convection (furnaces) or conduction (hot plates).

Unmatched Speed and Control

Heat is generated instantly and internally the moment the field is activated. There is no need to wait for a furnace to warm up or for heat to slowly conduct from the outside surface. This allows for extremely fast and repeatable heating cycles.

Superior Purity and Cleanliness

Since the process is non-contact and involves no combustion, there is no flame, smoke, or pollutant to contaminate the product. This is critical in sensitive applications like metallurgy, semiconductor manufacturing, and medical device fabrication.

Focused, Targeted Heat

The magnetic field can be precisely controlled by the shape of the induction coil. This allows heat to be applied to very specific areas of a part, leaving the rest of the assembly cool and unaffected—a level of precision impossible with most other methods.

High Energy Efficiency

Heat is generated only in the target material. Very little energy is wasted heating the surrounding atmosphere or equipment. This makes induction a "green" technology that is significantly more energy-efficient than a traditional furnace.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Understanding its limitations is crucial for making an informed decision.

Material Dependency

Induction heating works best with electrically conductive materials, primarily metals. Non-conductive materials like plastics or ceramics cannot be heated directly and require a conductive graphite crucible to act as an intermediary.

Initial Equipment Cost

The power supplies, custom coils, and cooling systems required for an industrial induction setup can represent a higher upfront investment compared to a simple gas furnace or resistance heater.

Coil Design and Geometry

For optimal performance and efficiency, the induction coil must be carefully engineered to match the specific size and shape of the part being heated. This may require custom design work for complex geometries.

Making the Right Choice for Your Goal

Selecting a heating method depends entirely on your project's priorities.

- If your primary focus is speed and high-volume production: Induction heating's rapid, repeatable cycle times are a definitive advantage.

- If your primary focus is product purity and eliminating contamination: Induction is the ideal choice due to its non-contact, flame-free nature.

- If your primary focus is precision and localized heating: The targeted application of heat via custom coils offers unparalleled control.

- If your primary focus is energy efficiency and sustainability: The targeted nature of induction minimizes wasted energy and eliminates harmful emissions.

Ultimately, induction heating provides a level of speed, precision, and cleanliness that traditional heating methods struggle to match.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Unmatched Speed | Instant internal heat generation | High-volume production |

| Superior Purity | Non-contact, flame-free process | Sensitive applications (e.g., medical, semiconductor) |

| Focused Heat | Precise, localized heating via custom coils | Targeted applications |

| High Energy Efficiency | Heat generated only in the target material | Sustainable, cost-effective operations |

Ready to enhance your lab's heating processes with the precision of induction? KINTEK specializes in advanced lab equipment, including induction heating systems, to help you achieve faster cycle times, superior purity, and unmatched energy efficiency. Let our experts tailor a solution to your specific needs. Contact us today to discuss how we can support your laboratory's goals!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- Why is heating rate control essential for LOCA simulation tests? Ensure Precision in Nuclear Safety Research

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- How does the vacuum hot pressing process improve wettability? Unlock Superior Diamond Product Bonding Strength