Determining the true cost of joining metal requires looking beyond the sticker price of equipment or consumables. While brazing can be significantly cheaper in automated, high-volume production, welding is often the more economical choice for low-volume or repair work where labor and setup costs are the primary drivers. The final answer depends entirely on the scale of your project, the materials being joined, and the required strength of the final part.

The core economic trade-off is this: brazing often exchanges higher material costs (expensive filler alloys) for lower labor and energy costs, making it ideal for automation. Welding typically involves lower material costs but demands more skilled labor and energy, making it suitable for custom or heavy-duty fabrication.

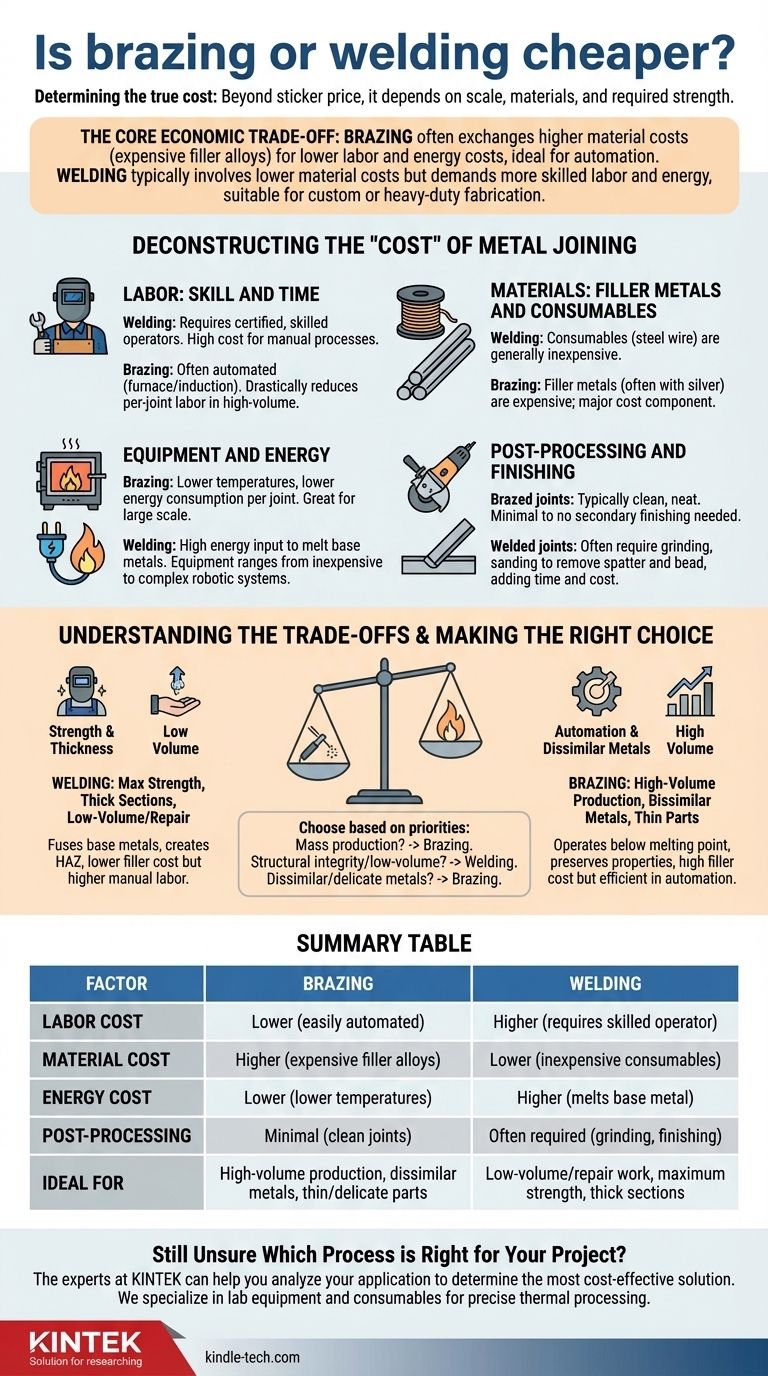

Deconstructing the "Cost" of Metal Joining

The total cost of a joining process is a sum of multiple factors, not a single line item. Understanding these components is critical to making an informed decision.

Labor: Skill and Time

Welding, especially for structural applications, demands a certified and skilled operator. This specialized labor is a significant cost driver, particularly for manual processes.

Brazing can often be automated, especially in furnace or induction brazing setups. This drastically reduces the per-joint labor cost in high-volume manufacturing, making it highly economical at scale.

Materials: Filler Metals and Consumables

Welding consumables, such as steel wire or rods, are generally inexpensive. The cost is low because they are often made of common industrial metals.

Brazing filler metals, by contrast, frequently contain high percentages of silver to lower their melting point and improve flow. This makes the filler material itself a major cost component of the brazing process.

Equipment and Energy

Brazing occurs at much lower temperatures than welding, as it does not melt the base metals. This translates directly into lower energy consumption per joint, a significant saving in large-scale production runs.

Welding requires high energy input to melt the base metals and create a fusion bond. The equipment can range from relatively inexpensive stick welders to highly complex and costly robotic systems.

Post-Processing and Finishing

Brazed joints are typically very clean and neat, often requiring little to no secondary grinding or finishing. This "net-shape" joining process saves significant time and labor downstream.

Welded joints often have spatter and an uneven bead that requires grinding, sanding, or other finishing steps to meet aesthetic or functional requirements, adding to the total project time and cost.

When Welding is Typically More Cost-Effective

Despite the potential for automation in brazing, welding remains the go-to choice for many common scenarios due to its inherent simplicity and strength.

Low-Volume or One-Off Projects

For repairs or small-batch fabrication, the setup for manual welding is fast and straightforward. The higher cost of skilled labor is offset by the minimal preparation and lower cost of filler materials compared to brazing.

Applications Requiring Maximum Strength

Welding fuses the base metals, creating a joint that can be as strong as, or even stronger than, the materials themselves. When absolute strength and structural integrity are the primary concerns, welding is the superior technical and often more direct, cost-effective choice.

Joining Thick Sections of Similar Metals

Welding excels at penetrating thick materials to create a deep, robust bond. The high heat input is necessary for these applications, whereas brazing would struggle to heat a large thermal mass evenly to the required temperature.

Understanding the Trade-offs

Choosing between brazing and welding is an exercise in balancing competing priorities. There is no universally "better" or "cheaper" method.

Strength vs. Material Integrity

Welding creates the strongest possible bond but at a cost. The intense heat creates a heat-affected zone (HAZ) that can alter the mechanical properties of the base metal, potentially making it more brittle.

Brazing operates below the melting point of the base metals, leaving their properties largely intact. The joint is weaker than a welded one but often more than strong enough for the application, and it avoids the risk of thermal distortion, which is critical for thin or delicate parts.

Filler Metal Cost vs. Automation Potential

The high cost of silver-based brazing alloys is a significant hurdle. However, this cost can be precisely controlled in an automated process where the exact amount of filler is applied every time, minimizing waste.

The low cost of welding wire is attractive, but manual welding can lead to overwelding and higher waste, and the associated labor cost per joint remains high without a major investment in robotics.

Joining Dissimilar Metals

Brazing's greatest technical advantage is its ability to join dissimilar metals, such as copper to steel or aluminum to copper. Welding these materials together is often impossible due to their incompatible metallurgical properties. In these cases, brazing is the only viable option, making its cost justifiable.

Making the Right Choice for Your Application

To select the most economical process, you must evaluate your project's specific goals.

- If your primary focus is mass production and automation: Brazing is likely the more cost-effective path due to lower cycle times, reduced energy use, and minimal post-processing.

- If your primary focus is structural integrity on a low-volume project: Welding is almost always the cheaper and more direct solution, offering superior strength with minimal setup.

- If your primary focus is joining delicate, thin, or dissimilar metals: Brazing is the superior technical choice, and its cost is justified by its unique capabilities that welding cannot match.

Ultimately, an informed decision comes from analyzing the total cost of the finished part—not just the process itself.

Summary Table:

| Factor | Brazing | Welding |

|---|---|---|

| Labor Cost | Lower (easily automated) | Higher (requires skilled operator) |

| Material Cost | Higher (expensive filler alloys) | Lower (inexpensive consumables) |

| Energy Cost | Lower (lower temperatures) | Higher (melts base metal) |

| Post-Processing | Minimal (clean joints) | Often required (grinding, finishing) |

| Ideal For | High-volume production, dissimilar metals, thin/delicate parts | Low-volume/repair work, maximum strength, thick sections |

Still Unsure Which Process is Right for Your Project?

Choosing between brazing and welding is a critical decision that impacts your budget, timeline, and product quality. The experts at KINTEK can help you analyze your specific application—whether you're in high-volume manufacturing or need a custom repair—to determine the most cost-effective and technically sound metal joining solution.

We specialize in providing the lab equipment and consumables necessary for precise thermal processing, including brazing and heat treatment applications. Let us help you optimize your process for efficiency and performance.

Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What happens when you compress hot metal? A Guide to Plastic Deformation & Recrystallization

- What is vacuum hot pressing? Achieve Maximum Density & Purity in Advanced Materials

- What is the hot pressing method of sintering? A Guide to High-Density Material Fabrication

- Why is pressing force important in sintering? Achieve Denser, Stronger Materials Faster

- What is pressure-assisted sintering? Achieve Denser, Stronger Materials Faster