The most effective materials for induction heating are ferromagnetic metals like carbon steel, cast iron, and certain grades of stainless steel. These materials heat exceptionally well because they benefit from two distinct physical phenomena: eddy current resistance and magnetic hysteresis. While other conductive metals like aluminum and copper can be heated, they are significantly less efficient and require more specialized equipment.

The "best" material is not a single alloy, but a category defined by two key properties: high magnetic permeability and high electrical resistivity. Understanding how these two factors work together is the key to selecting a material that heats quickly, efficiently, and predictably for your specific application.

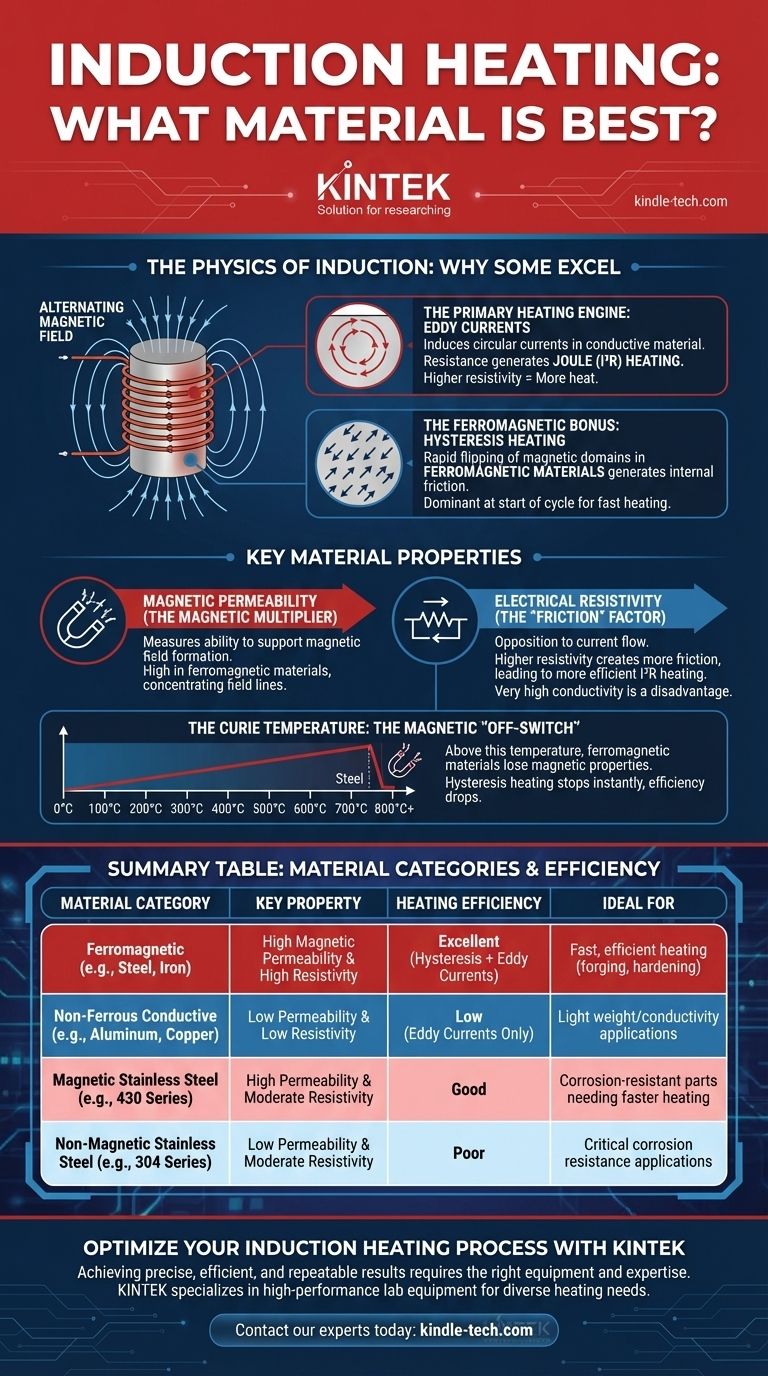

The Physics of Induction: Why Some Materials Excel

Induction heating works by creating a powerful, alternating magnetic field. A material's response to this field dictates how effectively it will heat. The process relies on one or both of two mechanisms.

The Primary Heating Engine: Eddy Currents

An alternating magnetic field induces circular electrical currents within any conductive material placed inside it. These are called eddy currents.

Every material has some level of electrical resistivity, which is resistance to the flow of current. As the eddy currents flow against this internal resistance, they generate friction-like heat. This is known as Joule or I²R heating.

A material with higher resistivity will generate more heat from the same amount of current, making it heat more effectively.

The Ferromagnetic Bonus: Hysteresis Heating

This second, powerful heating effect only occurs in ferromagnetic materials like iron, nickel, cobalt, and their alloys below a certain temperature.

These materials are composed of tiny magnetic regions called domains. The rapidly alternating magnetic field forces these domains to flip their magnetic polarity back and forth millions of times per second.

This rapid flipping creates immense internal friction, which generates significant heat. Hysteresis is often the dominant heating factor at the start of the cycle, allowing for extremely fast heating rates in magnetic materials.

Key Material Properties for Induction Heating

Two primary material properties determine the efficiency of induction heating. A third property, the Curie temperature, defines a critical limit.

Magnetic Permeability: The Magnetic Multiplier

Magnetic permeability is a measure of a material's ability to support the formation of a magnetic field.

Ferromagnetic materials have a very high permeability. They effectively concentrate the magnetic field lines, leading to much stronger eddy currents and enabling the powerful hysteresis heating effect. Non-magnetic materials like aluminum and copper have low permeability.

Electrical Resistivity: The "Friction" Factor

Electrical resistivity is the material's inherent opposition to the flow of electrical current.

While a material must be conductive to support eddy currents, very high conductivity (low resistivity) is actually a disadvantage. In materials like copper, eddy currents flow so easily that they generate very little resistive heat.

A material with higher resistivity, like steel, creates more "friction" against the eddy currents, resulting in more efficient I²R heating.

The Curie Temperature: The Magnetic "Off-Switch"

Every ferromagnetic material has a Curie temperature. Above this temperature, the material loses its magnetic properties and its permeability drops to that of free space.

For steel, this happens around 770°C (1420°F). At this point, all hysteresis heating stops instantly. The heating rate will noticeably decrease, as only the less efficient eddy current mechanism remains.

Understanding the Trade-offs

Choosing a material is rarely just about heating efficiency. The material's final function is paramount, creating a need for careful compromises.

Efficiency vs. Application Requirements

The most efficient material for heating, like a simple low-carbon steel, may not meet the needs of the final part, which might require the corrosion resistance of stainless steel or the light weight of aluminum.

You must balance the ideal process with the required outcome. For example, if you need to induction-braze a stainless steel part, you must accept that a non-magnetic grade (like 304) will heat far slower than a magnetic one (like 430).

The Critical Role of Frequency

The frequency of the alternating magnetic field is a key process variable that can be adjusted to compensate for material properties.

Non-magnetic, low-resistivity materials like aluminum require very high frequencies to generate sufficient heat. In contrast, large magnetic steel parts heat best with low frequencies that allow the magnetic field to penetrate deeper into the part.

Part Geometry and Coupling

The shape, size, and thickness of the workpiece also dramatically affect efficiency. A thin, flat part couples with the magnetic field differently than a thick, round bar. The design of the induction coil must be matched to the part geometry and material for optimal energy transfer.

Making the Right Choice for Your Goal

Your choice of material directly impacts process time, energy consumption, and equipment requirements. Base your decision on the primary objective of your application.

- If your primary focus is maximum heating speed and efficiency: Choose ferromagnetic materials like carbon steels or cast iron. Their high permeability and resistivity provide the fastest and most energy-efficient results.

- If your primary focus is heating a corrosion-resistant part: Select a magnetic grade of stainless steel (like the 400 series) over a non-magnetic austenitic grade (like the 300 series) whenever possible to improve the heating rate.

- If you must heat a non-ferrous material like aluminum or copper: Be prepared for a less efficient process. You will likely need a power supply capable of delivering higher power at a much higher frequency to achieve your desired heating rate.

By understanding how a material's fundamental properties interact with a magnetic field, you can make informed decisions that ensure a predictable and successful induction heating process.

Summary Table:

| Material Category | Key Property | Heating Efficiency | Ideal For |

|---|---|---|---|

| Ferromagnetic (e.g., Steel, Iron) | High Magnetic Permeability & High Resistivity | Excellent (Hysteresis + Eddy Currents) | Fast, efficient heating (forging, hardening) |

| Non-Ferrous Conductive (e.g., Aluminum, Copper) | Low Permeability & Low Resistivity | Low (Eddy Currents Only) | Applications requiring material properties like light weight/conductivity |

| Magnetic Stainless Steel (e.g., 430 Series) | High Permeability & Moderate Resistivity | Good | Corrosion-resistant parts needing faster heating |

| Non-Magnetic Stainless Steel (e.g., 304 Series) | Low Permeability & Moderate Resistivity | Poor | Applications where corrosion resistance is critical |

Optimize Your Induction Heating Process with KINTEK

Choosing the right material is just the first step. Achieving precise, efficient, and repeatable results requires the right equipment and expertise.

KINTEK specializes in high-performance lab equipment and consumables, serving diverse laboratory heating and materials processing needs. Whether you are working with ferromagnetic metals, non-ferrous alloys, or specialized materials, our solutions are designed to deliver superior control and reliability.

Let us help you enhance your lab's capabilities. Contact our experts today to discuss your specific application and discover the perfect heating solution for your requirements.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- High Purity Zinc Foil for Battery Lab Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What is SiC elements? The Ultimate High-Temperature Heating Solution