For producing graphene in bulk at the lowest possible cost, the most common method is liquid-phase exfoliation (LPE) of graphite. This approach sacrifices the pristine, single-layer quality found in more expensive methods, but it excels at creating large quantities of graphene flakes suitable for applications like composites, inks, and coatings. The "cheapest" method, however, is entirely dependent on your required quality and production volume.

The core issue is not finding a single "cheapest" method, but understanding the fundamental trade-off between production cost, material quality, and scalability. The most cost-effective approach is the one that produces graphene with the minimum acceptable quality for your specific application at the scale you require.

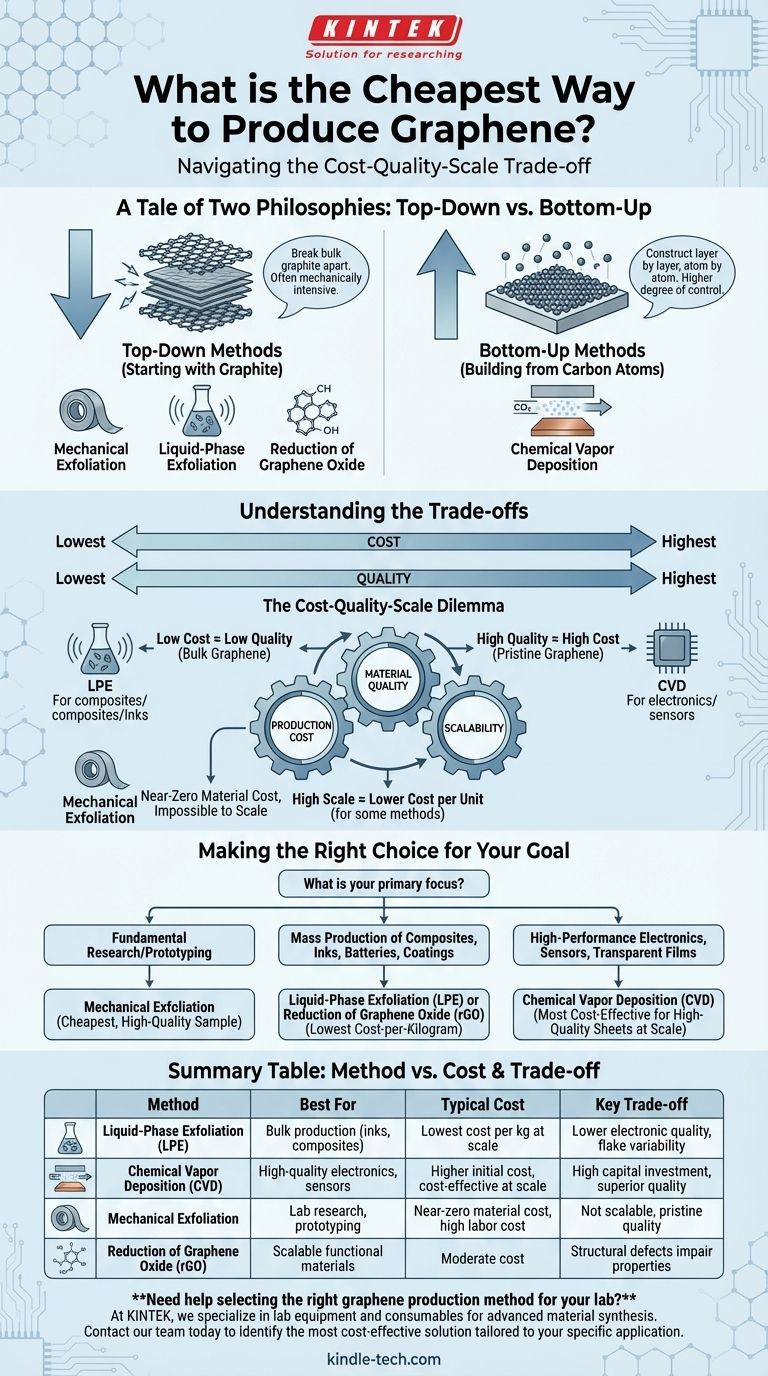

A Tale of Two Philosophies: Top-Down vs. Bottom-Up

Graphene production generally follows two distinct strategies. Understanding this division is the first step in choosing the right method for your budget and technical needs.

Top-Down Methods: Starting with Graphite

Top-down methods begin with graphite—a bulk material made of stacked graphene layers—and break it apart. These are often mechanically intensive processes.

Mechanical Exfoliation This is the original "Scotch tape" method, where tape is used to peel layers from a piece of graphite. While it can produce extremely high-quality, pristine single flakes of graphene, it is a manual, low-yield process. It is exceptionally cheap for lab-scale research and fundamental studies but is impossible to scale for industrial production.

Liquid-Phase Exfoliation (LPE) LPE involves submerging graphite in a liquid and using high-energy processes like sonication to break it apart and disperse graphene flakes. This method is excellent for mass production and is a leading candidate for the lowest cost-per-gram at scale. However, the resulting material consists of flakes with varying thicknesses and defects, leading to lower electrical quality compared to other methods.

Reduction of Graphene Oxide (GO) Another common top-down approach involves chemically oxidizing graphite to form graphene oxide, which separates into single layers easily in water. This GO is then "reduced" to remove the oxygen groups. While scalable and relatively inexpensive, the resulting reduced graphene oxide (rGO) contains structural defects that impair its properties.

Bottom-Up Methods: Building from Carbon Atoms

Bottom-up methods construct graphene layer by layer, atom by atom, on a substrate. This provides a much higher degree of control over the final product's quality.

Chemical Vapor Deposition (CVD) CVD is widely considered the most promising method for high-quality, large-area graphene. In this process, a carbon-containing gas is heated in a furnace, causing carbon atoms to deposit onto a metallic substrate (often copper) as a continuous, single-atomic layer. While the initial equipment cost is higher than for LPE, CVD is the leading technique for producing the high-purity graphene required for advanced electronics.

Understanding the Trade-offs: Cost vs. Quality vs. Scale

Choosing a production method requires a clear understanding of its inherent compromises. The cheapest option is rarely the best, and the best is rarely the cheapest.

The Cost-Quality Spectrum

There is a direct relationship between production cost and material quality. Low-cost methods like liquid-phase exfoliation produce what is best described as "bulk graphene"—a collection of multi-layer flakes with defects. This is perfectly suitable for enhancing the mechanical strength of polymers or creating conductive inks.

Conversely, high-quality, single-layer sheets from CVD are essential for applications that rely on graphene's exceptional electronic properties, such as high-frequency transistors or transparent sensors. The cost is justified by the performance.

The Cost-Scale Dilemma

A method's cost is also tied to production volume. Mechanical exfoliation has near-zero material cost but an infinitely high cost at an industrial scale due to labor and nonexistent throughput.

CVD has a significant initial capital investment for reactors and vacuum systems, but the cost per square meter of graphene can become very competitive at large-scale production, especially for high-value electronic applications.

The Problem of "Graphene" Itself

The term "graphene" is often used to describe different materials. The powder of graphene flakes from LPE has different properties and costs than the large, transparent film of single-layer graphene grown via CVD. Clarifying which type of graphene you need is the most critical step in determining your true cost.

Making the Right Choice for Your Goal

Your application's specific requirements should dictate your choice of production method. There is no universally superior option, only the right tool for the job.

- If your primary focus is fundamental research or prototyping a single, small device: Mechanical exfoliation is the cheapest and most straightforward way to obtain a high-quality sample.

- If your primary focus is mass production of composites, inks, batteries, or coatings: Liquid-phase exfoliation or the reduction of graphene oxide offers the lowest cost-per-kilogram for bulk graphene materials.

- If your primary focus is high-performance electronics, sensors, or transparent conductive films: Chemical Vapor Deposition (CVD) is the most cost-effective method for producing the required large, high-quality, single-layer sheets at scale.

Ultimately, aligning your production method with your end goal is the only way to achieve a truly cost-effective outcome.

Summary Table:

| Method | Best For | Typical Cost | Key Trade-off |

|---|---|---|---|

| Liquid-Phase Exfoliation (LPE) | Bulk production (inks, composites) | Lowest cost per kg at scale | Lower electronic quality, flake variability |

| Chemical Vapor Deposition (CVD) | High-quality electronics, sensors | Higher initial cost, cost-effective at scale | High capital investment, superior quality |

| Mechanical Exfoliation | Lab research, prototyping | Near-zero material cost, high labor cost | Not scalable, pristine quality |

| Reduction of Graphene Oxide (rGO) | Scalable functional materials | Moderate cost | Structural defects impair properties |

Need help selecting the right graphene production method for your lab? The choice between cost, quality, and scale is critical. At KINTEK, we specialize in lab equipment and consumables for advanced material synthesis, including graphene production. Our experts can help you identify the most cost-effective solution tailored to your specific application—whether you're developing composites, electronics, or coatings. Contact our team today to discuss your project and discover how KINTEK can support your innovation with the right tools and expertise.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- Are all lab grown diamonds CVD? Understanding the Two Main Methods

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What are nanotubes drawbacks? The 4 Major Hurdles Limiting Their Real-World Use

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit