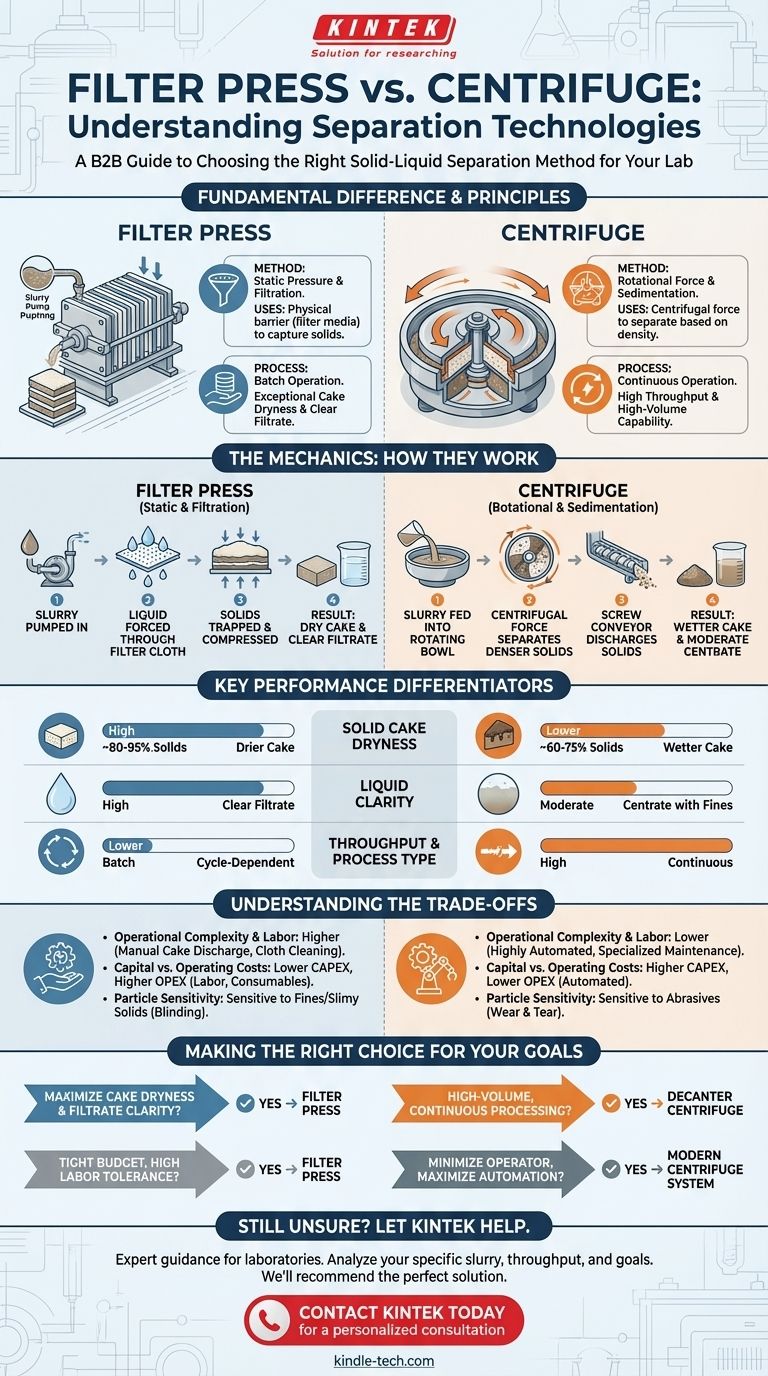

At a fundamental level, the difference between a filter press and a centrifuge lies in their method of separation. A filter press uses static pressure to force a liquid through a physical barrier (filter media), capturing the solids. In contrast, a centrifuge uses high-speed rotation to generate centrifugal force, which separates materials based on their density, forcing denser solids to the outside while the lighter liquid is removed from the center.

The choice between these technologies is a classic engineering trade-off. Filter presses excel at producing an exceptionally dry solid cake and clear liquid filtrate in a batch process, while centrifuges provide high-throughput, continuous operation, often at the cost of lower cake dryness.

The Mechanics of Separation: How They Work

To choose correctly, you must first understand the distinct operational principles of each machine. They achieve the same goal—solid-liquid separation—through entirely different physical forces.

The Filter Press: Static Pressure and Filtration

A filter press operates like a high-pressure, industrial-scale coffee filter. A slurry is pumped into a series of chambers lined with filter cloths.

High-pressure pumps force the liquid component of the slurry through the pores of the filter cloth, leaving the solid particles behind. These trapped solids accumulate and compress under pressure, forming a dense, dry "cake."

The process is a batch operation: it involves filling the press, applying pressure, discharging the solid cakes, and preparing for the next cycle. The resulting liquid, known as filtrate, is typically very clear because it has passed through a physical barrier.

The Centrifuge: Rotational Force and Sedimentation

A decanter centrifuge works on the principle of accelerated gravity, much like a salad spinner. It consists of a solid bowl rotating at extremely high speed.

When slurry is fed into the rotating bowl, it is subjected to immense centrifugal forces—often thousands of times the force of gravity. This force rapidly throws the denser solid particles against the inner wall of the bowl.

An internal screw conveyor (scroll), rotating at a slightly different speed, continuously scrapes these compacted solids toward one end for discharge. The lighter liquid, or centrate, forms an inner layer and overflows out the other end. This is a continuous process.

Key Performance Differentiators

The mechanical differences directly translate into distinct performance outcomes. Your specific process requirements for dryness, clarity, and volume will dictate which technology is more suitable.

Solid Cake Dryness

A filter press almost always produces a drier solid cake. The final mechanical squeezing phase can achieve very high levels of dewatering, often resulting in a cake with the highest possible percentage of solids.

A centrifuge typically produces a wetter cake. While effective, it relies solely on centrifugal force for compaction and cannot apply the final mechanical "squeeze" that a press can.

Filtrate (Liquid) Clarity

Because a filter press uses a physical filter medium, it generally produces a cleaner filtrate. The cloth acts as an absolute barrier to particles larger than its pore size.

Centrifuge performance depends on the density difference between the solid and liquid. Very fine or low-density particles may not separate completely and can remain suspended in the centrate, leading to lower clarity.

Throughput and Process Type

Centrifuges are built for high-throughput, continuous operation. They are ideal for processing large, uninterrupted streams of material 24/7 with minimal downtime.

Filter presses are batch systems. Their overall throughput is limited by the cycle time required to fill, press, open, discharge the cakes, and close the unit again.

Understanding the Trade-offs

Neither technology is universally superior. The optimal choice depends on balancing performance goals with operational realities like cost, labor, and material characteristics.

Operational Complexity and Labor

A filter press is often more labor-intensive. Discharging the cakes can be a manual or semi-automated process, and the filter cloths require regular cleaning and eventual replacement, which involves significant downtime.

A centrifuge is highly automated and requires far less operator intervention during normal operation. However, its high-speed rotating components demand specialized preventative maintenance and can be more complex to service.

Capital vs. Operating Costs

Capital expenditure (CAPEX) for a filter press is often lower than for a centrifuge of equivalent capacity. However, its operating expenditure (OPEX) can be higher due to labor costs and consumables like filter cloths.

Centrifuges may have a higher initial purchase price and consume more energy due to the large motors required. Their automated nature, however, can lead to lower long-term labor costs.

Particle and Slurry Sensitivity

Filter presses can be sensitive to very fine or "slimy" solids, which can "blind" or clog the filter cloths, drastically reducing efficiency.

Centrifuges can be sensitive to abrasive particles, which can cause rapid wear on the internal scroll and bowl, leading to expensive repairs. They also may struggle with slurries where the density difference between the solid and liquid is very small.

Making the Right Choice for Your Separation Goal

Your decision should be driven by a clear definition of your primary objective.

- If your primary focus is maximizing cake dryness and filtrate clarity: A filter press is the superior choice, especially when these quality metrics are non-negotiable.

- If your primary focus is high-volume, continuous processing: A decanter centrifuge is the industry standard for handling large, uninterrupted flows with minimal labor.

- If you are on a tight capital budget but can accommodate higher labor costs: A filter press often presents a lower initial investment.

- If minimizing operator intervention and maximizing automation is the top priority: A modern centrifuge system offers a more hands-off, continuous solution.

By understanding these core operational differences, you can confidently select the technology that aligns directly with your process requirements and economic goals.

Summary Table:

| Feature | Filter Press | Centrifuge |

|---|---|---|

| Separation Principle | Static pressure & filtration | Centrifugal force & sedimentation |

| Process Type | Batch | Continuous |

| Cake Dryness | High (drier cake) | Lower (wetter cake) |

| Liquid Clarity | High (clear filtrate) | Moderate (can have fines in centrate) |

| Throughput | Lower (cycle-dependent) | High (continuous flow) |

| Operational Labor | Higher (manual cake discharge) | Lower (highly automated) |

| Ideal For | Maximum dryness/clarity, batch processing | High-volume, continuous processing |

Still Unsure Which Separation Technology is Best for Your Lab?

Choosing between a filter press and a centrifuge is critical for your process efficiency and product quality. The wrong choice can lead to subpar results and increased operational costs.

KINTEK is here to help. We specialize in lab equipment and consumables, providing expert guidance to laboratories like yours. We can help you analyze your specific slurry characteristics, throughput requirements, and quality goals to recommend the perfect solution—whether it's a high-dryness filter press or a high-throughput centrifuge.

Let our experts guide you to the optimal solution for your specific application.

Contact KINTEK today for a personalized consultation and discover how our separation technologies can enhance your lab's performance and reliability.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- How does pressure affect hydraulic system? Mastering Force, Efficiency, and Heat

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- How much pressure can a hydraulic press make? From 1 Ton to 75,000+ Tons of Force

- Why do we use KBr in FTIR? The Key to Clear, Accurate Solid Sample Analysis

- How much force can a hydraulic press exert? Understanding its immense power and design limits.