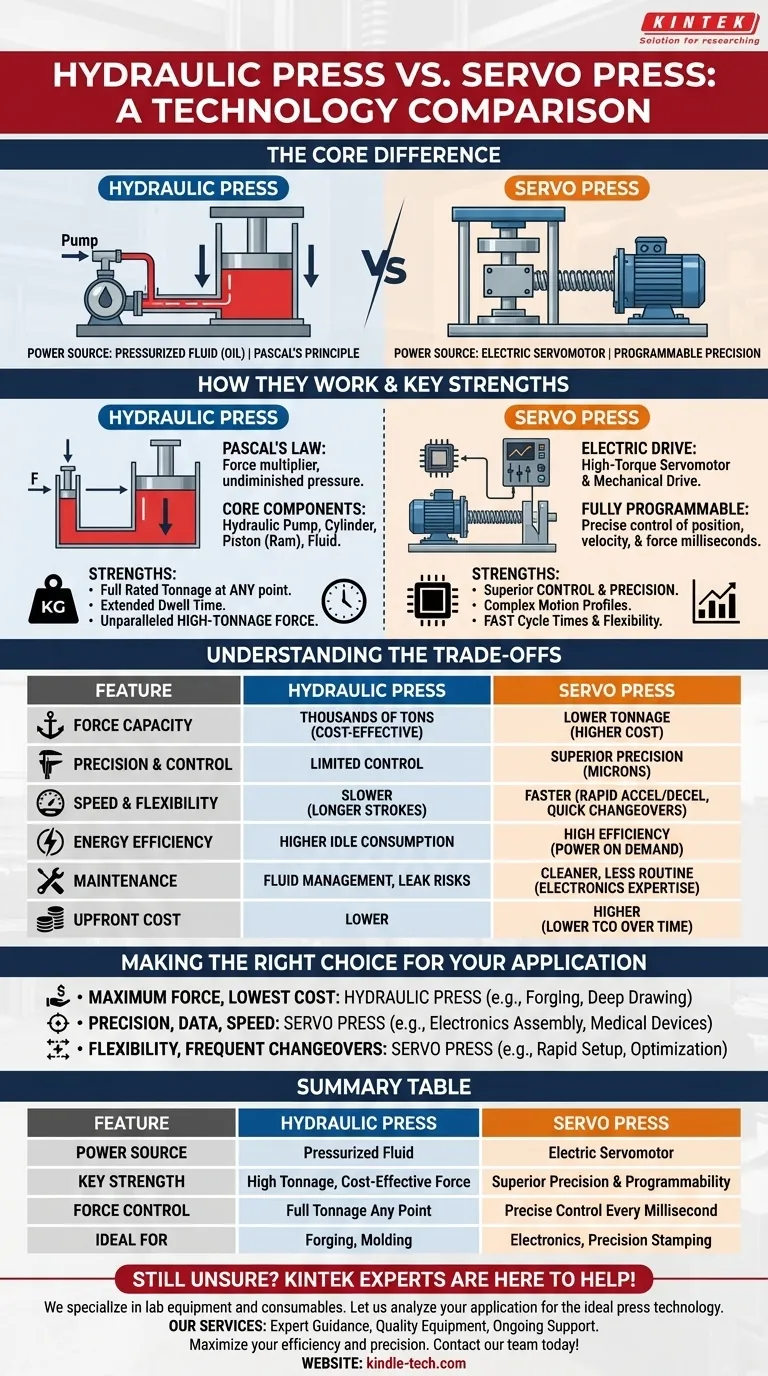

At their core, the fundamental difference between a hydraulic press and a servo press lies in their power source and method of control. A hydraulic press uses pressurized fluid, typically oil, to generate immense force based on Pascal's principle. In contrast, a servo press uses a high-torque electric servomotor linked to a ball screw or roller screw to deliver force with extreme precision and programmability.

The choice between them is a classic engineering trade-off: hydraulic presses offer unparalleled, cost-effective force, while servo presses provide superior control, speed, and data feedback throughout the entire forming process.

How a Hydraulic Press Works

A hydraulic press is a time-tested technology known for its ability to generate massive force from a relatively simple design. Its operation is governed by the principles of fluid dynamics.

The Principle of Pascal's Law

The foundation of any hydraulic press is Pascal's Law, which states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

This allows the press to act as a force multiplier. A small force applied by a pump over a small area creates pressure in the fluid, which then acts on a much larger piston, generating a proportionally larger output force.

Core Components and Operation

The system consists of a hydraulic pump, a cylinder, a piston (the ram), and hydraulic fluid. The pump forces the fluid into the cylinder, driving the piston down to perform the work.

Because the force is generated by fluid pressure, a hydraulic press can apply its full rated tonnage at any point in the stroke and can maintain that force for an extended period, a capability known as dwell time.

How a Servo Press Works

A servo press represents a more modern, data-driven approach to forming. It replaces fluid power with direct electromechanical force, offering a level of control that hydraulic systems cannot match.

The Electric Drive System

The heart of the press is a high-torque electric servomotor. This motor is connected to a mechanical drive, most commonly a high-precision ball screw or roller screw, which converts the motor's rotational motion into the linear motion of the ram.

This direct mechanical linkage eliminates the variables associated with hydraulic fluid, such as temperature, viscosity, and potential leaks.

Fully Programmable Motion

The single greatest advantage of a servo press is its programmability. The servomotor's controller can precisely manage the ram's position, velocity, and the force it applies at every millisecond of the stroke.

This allows for complex motion profiles, such as slowing down just before contacting the workpiece to reduce shock, applying a specific force profile during forming, and retracting at maximum speed to improve cycle times.

Understanding the Trade-offs: A Direct Comparison

Choosing the right press technology requires a clear-eyed assessment of your specific application's needs. Each system has distinct advantages and disadvantages.

Force Capacity

Hydraulic presses are the undisputed leaders in high-tonnage applications. They can generate thousands of tons of force far more cost-effectively than a servo press of equivalent power.

Precision and Control

Servo presses are the clear winner. They offer full control over the entire stroke, with positioning accuracy often measured in microns. This is critical for delicate assembly, precision stamping, and applications requiring detailed process data.

Speed and Flexibility

For overall cycle time, servo presses are often faster, especially on shorter strokes, due to their rapid acceleration and deceleration capabilities. Their programmability also makes them far more flexible for facilities with frequent job changeovers.

Energy Efficiency

Servo presses consume significant power only when the ram is in motion. Hydraulic press pumps, by contrast, often run continuously to maintain system pressure, resulting in higher idle energy consumption.

Maintenance and Environment

Hydraulic systems require diligent fluid management to prevent leaks, contamination, and overheating. Servo presses are cleaner and require less routine maintenance, though troubleshooting their complex electronics can be more specialized.

Upfront vs. Operating Cost

Hydraulics typically have a lower initial purchase price for a given tonnage. Servo presses have a higher upfront cost but often deliver a lower total cost of ownership through energy savings, reduced maintenance, and higher productivity.

Making the Right Choice for Your Application

The ideal press is the one that best matches the demands of your material, your part, and your production environment.

- If your primary focus is maximum forming force at the lowest cost: A hydraulic press is the proven solution for high-tonnage jobs like deep drawing, forging, or molding.

- If your primary focus is precision, data collection, and speed: A servo press is superior for applications like electronics assembly, medical device manufacturing, or high-speed coining.

- If your primary focus is flexibility and frequent changeovers: The programmability of a servo press allows for rapid setup and optimization, drastically reducing downtime between different jobs.

Understanding the core technology of each press empowers you to select the right tool that aligns perfectly with your operational and financial goals.

Summary Table:

| Feature | Hydraulic Press | Servo Press |

|---|---|---|

| Power Source | Pressurized Fluid (Oil) | Electric Servomotor |

| Key Strength | High Tonnage, Cost-Effective Force | Superior Precision & Programmability |

| Force Control | Full Tonnage at Any Stroke Point | Precise Control at Every Millisecond |

| Ideal For | Forging, Deep Drawing, Molding | Electronics Assembly, Medical Devices, Precision Stamping |

Still Unsure Which Press is Right for Your Lab or Production Line?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your specific application—whether it's high-force molding or precision assembly—to determine the ideal press technology for your budget and performance goals.

We provide:

- Expert Guidance: Unbiased advice to match you with the right press technology.

- Quality Equipment: Reliable hydraulic and servo presses for consistent results.

- Ongoing Support: Maintenance and consumables to keep your operations running smoothly.

Maximize your efficiency and precision. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- How much force can a hydraulic press exert? Understanding its immense power and design limits.