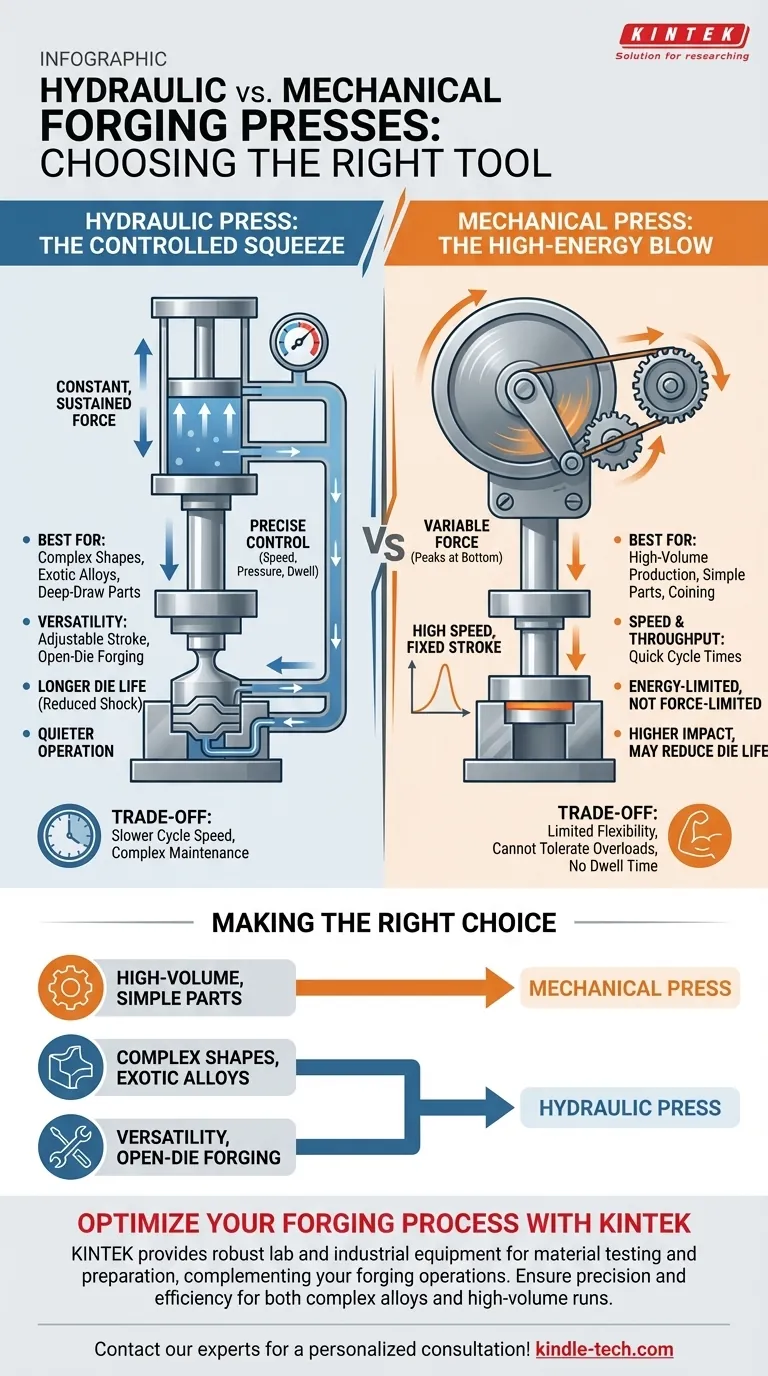

The fundamental difference between a hydraulic and a mechanical press is how they deliver force. A hydraulic press uses pressurized fluid to apply a constant, controlled force throughout its entire stroke, while a mechanical press uses a flywheel and crank mechanism to deliver a rapid blow of energy that peaks at the very bottom of its stroke.

The choice between them is not about which is superior, but which is appropriate for the task. Hydraulic presses offer unparalleled control and sustained force for complex forgings, while mechanical presses provide the speed and repeatability required for high-volume production.

The Core Mechanism: How They Apply Force

Understanding the operational principle of each press reveals its inherent strengths and weaknesses. The method of force delivery dictates everything from production speed to the types of parts that can be successfully forged.

Hydraulic Presses: The Controlled Squeeze

A hydraulic press operates on the principle of fluid dynamics. A pump moves hydraulic fluid into a cylinder, pushing a piston that drives the ram.

This design allows for constant and maximum force to be applied at any point during the ram's movement. The operator has precise control over the speed, pressure, and duration of the press stroke.

Mechanical Presses: The High-Energy Blow

A mechanical press stores energy in a large, spinning flywheel. When activated, a clutch connects the flywheel to a crank or eccentric gear, which drives the ram down in a single, rapid motion.

This press is energy-limited, not force-limited. Its force is variable, peaking only at the bottom dead center of the stroke. The stroke length is fixed, and the speed is largely determined by the gearing and motor.

Comparing Key Operational Characteristics

The differences in their core mechanisms lead to distinct advantages in different manufacturing scenarios.

Control and Precision

Hydraulic presses offer superior control. The ability to minutely adjust the forming speed and pressure is critical for forging sensitive alloys or complex shapes, resulting in higher workpiece quality.

Speed and Throughput

Mechanical presses are significantly faster. Their quick cycle times make them the undisputed choice for high-volume, automated production lines where thousands of identical parts must be made quickly.

Force Application

The sustained "squeeze" of a hydraulic press allows the metal to flow slowly and completely fill intricate die cavities. In contrast, the sharp impact of a mechanical press is ideal for coining or forging simpler shapes.

Versatility and Die Life

The adjustable stroke and controlled speed of a hydraulic press make it highly versatile for a wide range of products, including long components. This control also reduces shock, leading to longer die service life.

Understanding the Trade-offs

Neither press type is a perfect solution for every scenario. The choice involves balancing clear operational and financial trade-offs.

The Cost of Control (Hydraulic)

The primary drawback of a hydraulic press is its slower cycle speed, which limits throughput. The complex hydraulic systems can also require specialized maintenance to manage fluid quality and prevent leaks.

The Limit of Speed (Mechanical)

A mechanical press offers very little flexibility. Its fixed stroke and stroke-dependent force make it unsuitable for deep-draw parts or operations requiring a "dwell time" under pressure. Furthermore, they cannot tolerate overloads and can suffer catastrophic damage if a part is improperly placed.

Noise and Environment

Hydraulic presses are considerably quieter, as they have fewer high-impact moving parts. The operator's control over the process also helps manage noise levels, a significant factor in a manufacturing environment.

Making the Right Choice for Your Forging Goal

Your application's specific demands should dictate your choice of press technology.

- If your primary focus is high-volume production of simple parts: The unmatched speed and repeatability of a mechanical press are ideal.

- If your primary focus is forging complex shapes or exotic alloys: The precise control over force and speed in a hydraulic press is necessary for quality.

- If your primary focus is versatility for varied jobs and open-die forging: The adjustable stroke and constant force of a hydraulic press provide the most flexibility.

Ultimately, your decision hinges on a fundamental choice between the raw speed of a mechanical press and the deliberate control of a hydraulic one.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Delivery | Constant, sustained force throughout the stroke | Variable force, peaking at bottom of stroke |

| Speed & Throughput | Slower cycle time | High speed, ideal for high-volume production |

| Control & Precision | Superior control over speed, pressure, and dwell time | Limited control, fixed stroke |

| Best For | Complex shapes, exotic alloys, deep-draw parts, versatility | High-volume production of simple parts |

| Die Life | Longer die life due to reduced shock | Higher impact can reduce die life |

Optimize Your Forging Process with the Right Equipment

Choosing between a hydraulic and mechanical press is a critical decision that impacts your product quality, throughput, and bottom line. KINTEK specializes in providing robust lab and industrial equipment, including solutions for material testing and preparation that complement your forging operations.

Our expertise can help you select the right tools to ensure precision and efficiency, whether you're working with complex alloys or high-volume production runs.

Let's discuss your specific needs and find the perfect solution for your workshop. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy