At a fundamental level, the difference between PVD and CVD coating lies in the state of the material being deposited and the temperature required. PVD (Physical Vapor Deposition) is a low-temperature physical process that turns a solid material into a vapor to coat a part, while CVD (Chemical Vapor Deposition) is a high-temperature chemical process that uses precursor gases to create a solid coating through a chemical reaction on the part's surface.

The choice between PVD and CVD is not about which is universally "better," but which is appropriate for the task. The decision hinges almost entirely on the substrate material's tolerance for heat and the specific performance properties required of the final coated surface.

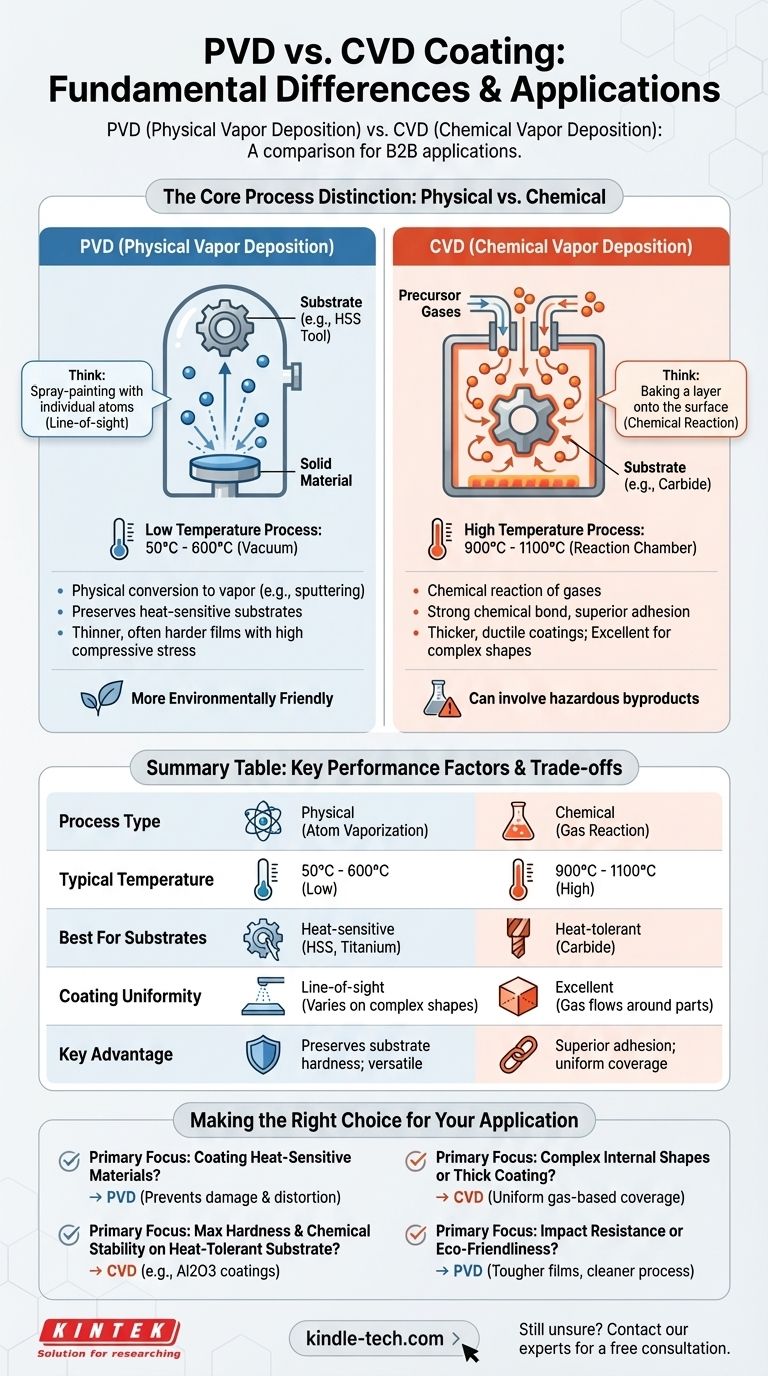

The Core Process Distinction: Physical vs. Chemical

The names themselves reveal the primary difference. One process is physical, the other is chemical, and this distinction has significant practical consequences.

How PVD Works (The Physical Method)

PVD is a low-temperature process, typically conducted between 50°C and 600°C in a vacuum chamber. Solid coating material is physically converted into a vapor through methods like sputtering or evaporation.

Think of this process like spray-painting with individual atoms. The vaporized material travels in a straight line (line-of-sight) and condenses on the substrate, forming a thin, hard film.

How CVD Works (The Chemical Method)

CVD is a high-temperature process, often requiring 900°C to 1100°C. It involves introducing volatile precursor gases into a reaction chamber.

These gases decompose and react on the heated substrate's surface, forming a new solid material—the coating. This is less like painting and more like baking a layer onto the surface, where the ingredients (gases) react to form a chemically bonded film.

Key Performance Factors and Applications

The differences in process temperature and deposition method directly influence how these coatings perform in real-world applications.

The Impact of Process Temperature

This is the most critical factor in selecting a process. The high heat of CVD can anneal, soften, or distort heat-sensitive materials.

For example, a high-speed steel (HSS) tool would lose its hardness and straightness if subjected to a high-temperature CVD process. For such materials, PVD is the ideal choice because its low application temperature preserves the substrate's structural integrity.

Coating Material and Adhesion

CVD historically excels at depositing certain materials, particularly Aluminum Oxide (Al2O3), which offers exceptional hardness, wear resistance, and chemical stability at a low cost. The high-temperature reaction creates a very strong chemical bond with the substrate.

While PVD technology has advanced to offer a wider range of materials, CVD's chemical bonding generally results in superior adhesion on substrates that can tolerate the heat.

Hardness and Lubricity

Both PVD and CVD coatings significantly improve a tool's performance by providing two key properties: high micro-hardness and lubricity (a low coefficient of friction).

The extreme hardness (often exceeding 80 Rc) protects against abrasive wear, while the lubricity reduces friction and heat generation, preventing material from sticking to the tool.

Understanding the Trade-offs

Choosing a coating requires an objective look at the advantages and disadvantages of each method.

Substrate Compatibility

This is the most significant trade-off. CVD is limited to materials that can withstand extreme heat without damage, such as carbide. PVD is far more versatile, suitable for coating steels, titanium alloys, and other materials that cannot tolerate the high temperatures of CVD.

Geometric Limitations

Because PVD is a line-of-sight process, it can struggle to uniformly coat complex internal geometries. CVD gases flow around the part, allowing for a more uniform and consistent coating on all exposed surfaces, which is a major advantage for intricate components.

Film Properties

CVD typically produces thicker, more ductile coatings with high adhesion. PVD films are thinner and can be more brittle but often exhibit higher compressive stress, which can help prevent crack propagation and improve impact resistance.

Environmental Impact

PVD is generally considered a more environmentally friendly process. It operates in a vacuum and does not produce hazardous byproducts. The precursor gases used in some CVD processes can be toxic or corrosive, requiring careful handling and disposal.

Making the Right Choice for Your Application

To select the correct process, you must prioritize your application's most critical requirement.

- If your primary focus is coating heat-sensitive materials (like HSS tools): PVD is the only viable choice due to its low process temperature, which prevents substrate damage and distortion.

- If your primary focus is maximum hardness and chemical stability on a heat-tolerant substrate (like carbide): CVD, especially with

Al2O3coatings, offers exceptional durability and strong chemical bonding. - If your primary focus is coating complex internal shapes or achieving a very thick coating: CVD's gas-based process provides more uniform coverage than the line-of-sight PVD process.

- If your primary focus is impact resistance or environmental friendliness: PVD is generally the superior option, offering tougher films and a cleaner operational footprint.

Ultimately, understanding the fundamental process differences empowers you to select the coating that will unlock the highest level of performance for your specific component.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (atom vaporization) | Chemical (gas reaction) |

| Typical Temperature | 50°C - 600°C (Low) | 900°C - 1100°C (High) |

| Best For Substrates | Heat-sensitive materials (HSS, titanium) | Heat-tolerant materials (carbide) |

| Coating Uniformity | Line-of-sight (may vary on complex shapes) | Excellent (gas flows around parts) |

| Key Advantage | Preserves substrate hardness; versatile | Superior adhesion; uniform coverage |

Still unsure which coating process is right for your application?

At KINTEK, we specialize in lab equipment and consumables for surface engineering. Our experts can help you select the ideal PVD or CVD solution to enhance your tool life, improve performance, and maximize ROI.

Contact us today to discuss your specific substrate and coating requirements → Get a Free Consultation

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method