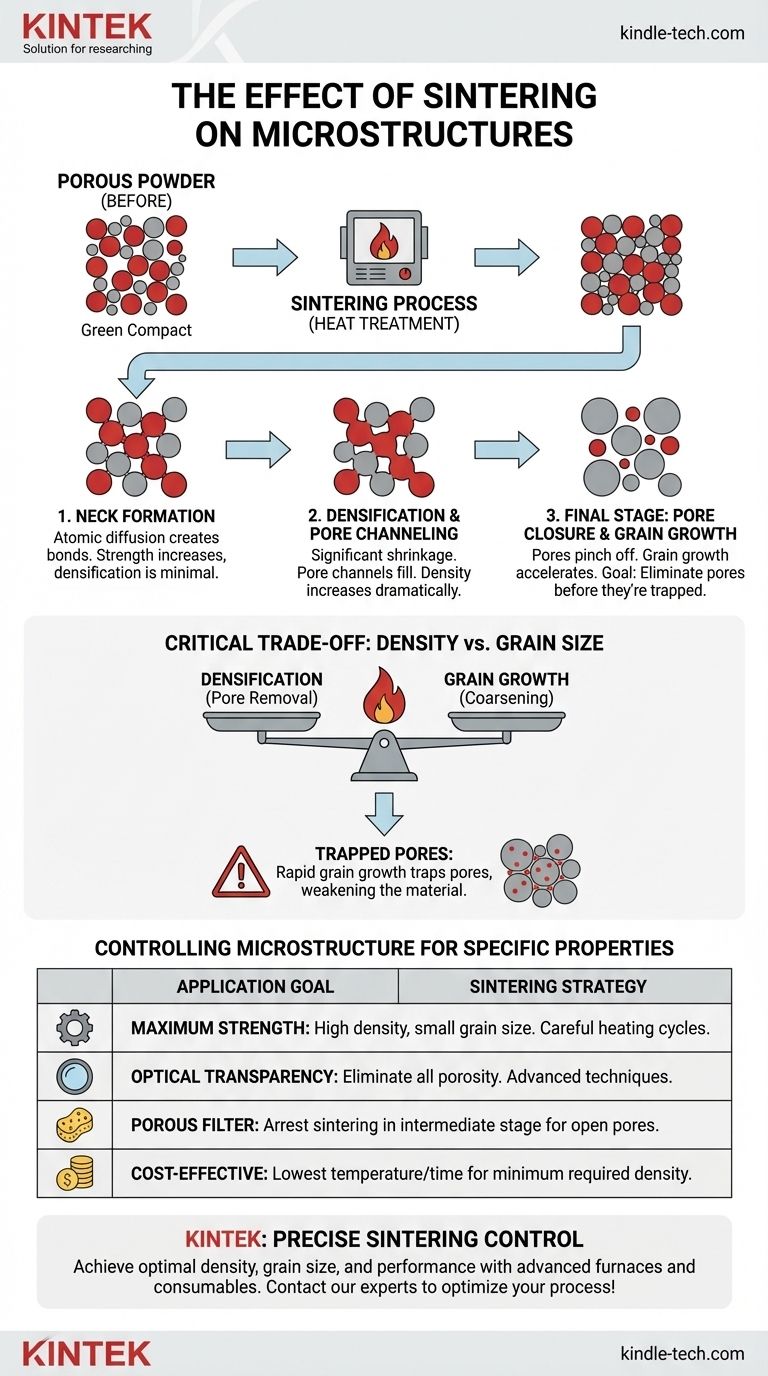

In essence, sintering is a heat treatment process that fundamentally transforms a porous collection of powder particles into a dense, solid object. This transformation is achieved by atomic diffusion, causing particles to bond together, pores to shrink and be eliminated, and grains to grow. The result is a dramatic change in the material's microstructure, which in turn dictates its final physical and mechanical properties.

Sintering is primarily a balancing act between two competing phenomena: densification (the removal of pores) and grain growth. The final microstructure is a direct consequence of how well you control this trade-off using process parameters like temperature, time, and atmosphere.

The Core Mechanisms of Sintering

To understand the effect on microstructure, you must first understand how sintering works. It is driven by the thermodynamic desire to reduce the high surface energy of a fine powder.

The Driving Force: Reduction of Surface Energy

A compact of fine powder has an enormous amount of surface area, which is a high-energy, thermodynamically unstable state. Sintering provides the thermal energy for atoms to move and reduce this surface area by bonding particles together and eliminating the voids between them.

Initial Stage: Neck Formation

At the beginning of the process, atoms diffuse to the contact points between adjacent powder particles. This creates small "necks" that bond the particles together. The powder compact gains significant strength, but overall densification is minimal during this stage.

Intermediate Stage: Densification and Pore Channeling

This is the stage where the most significant densification occurs. The necks grow larger, and the pores between particles form an interconnected network of channels. Atomic diffusion, primarily along grain boundaries, moves matter from the bulk of the particles to fill in these channels, causing the object to shrink and its density to increase dramatically.

Final Stage: Pore Closure and Grain Growth

As densification approaches its theoretical maximum, the pore channels pinch off, forming isolated, often spherical pores. At this stage, grain growth can accelerate significantly. The primary goal is to eliminate these final isolated pores before the grains grow so large that they trap the pores within them.

The Primary Microstructural Changes

Sintering directly architects the final internal structure of the material. The key changes are density, grain size, and pore morphology.

Densification: The Elimination of Porosity

The most obvious effect is the reduction of void space, or porosity. A "green" (unsintered) part might be 50-60% dense, but a fully sintered part can exceed 99% of its theoretical maximum density. This increase in density is directly responsible for improvements in properties like mechanical strength and thermal conductivity.

Grain Growth: The Coarsening of Crystals

As particles fuse and pores are eliminated, the original particle boundaries are replaced by grain boundaries. Driven by the same need to reduce energy, these grains will grow larger, consuming smaller grains. The final grain size is a critical microstructural feature that heavily influences hardness and fracture toughness.

Pore Shape and Distribution

During sintering, the shape of the pores evolves. Irregularly shaped voids between particles transform into a network of cylindrical channels and finally into small, isolated spherical pores. The final distribution of any remaining porosity is crucial; a small amount of porosity located at grain boundaries is far less damaging than pores trapped inside of grains.

Understanding the Trade-offs: Density vs. Grain Size

Achieving a desired microstructure is rarely simple. The process involves navigating a critical trade-off between densification and grain growth.

The Competing Processes

Densification and grain growth are competing processes that are both accelerated by higher temperatures and longer sintering times. The ideal process allows for rapid densification while simultaneously suppressing or controlling the rate of grain growth.

The Problem of Trapped Pores

If grain growth occurs too rapidly, a fast-moving grain boundary can sweep past a pore, trapping it inside the crystal lattice. Once a pore is trapped within a grain, it is extremely difficult to remove. These internal pores act as stress concentrators and are highly detrimental to the material's mechanical strength and properties like optical transparency in ceramics.

The Role of Sintering Parameters

The key to success is manipulating the sintering parameters. Temperature provides the energy for diffusion, time determines how long these processes run, and atmosphere can prevent oxidation and sometimes influence diffusion rates. Fine-tuning these variables is how you steer the microstructure toward the desired outcome.

Controlling Microstructure for Specific Properties

Your approach to sintering should be dictated by the end-use application of your component. By controlling the microstructural evolution, you can engineer the material's final performance.

- If your primary focus is maximum mechanical strength: You must prioritize achieving near-full density while keeping the final grain size as small as possible, which requires carefully optimized heating cycles.

- If your primary focus is optical transparency (for advanced ceramics): You must eliminate virtually all porosity, as even microscopic pores will scatter light. This often requires advanced techniques like pressure-assisted sintering.

- If your primary focus is creating a porous filter or support: You should intentionally arrest the sintering process in the intermediate stage to preserve an open, interconnected network of pores.

- If your primary focus is cost-effective manufacturing: You aim for the lowest temperature and shortest time that achieves the minimum required density and performance specifications for your application.

Ultimately, mastering sintering is about intentionally navigating the path of microstructural evolution to engineer the final material properties you require.

Summary Table:

| Microstructural Change | Effect on Material Properties |

|---|---|

| Densification (Pore Removal) | Increases strength, hardness, and thermal conductivity |

| Grain Growth | Affects toughness and hardness; requires careful control |

| Pore Shape Evolution | Determines final porosity distribution and material integrity |

| Trade-off: Density vs. Grain Size | Critical for balancing mechanical strength and manufacturing efficiency |

Ready to engineer your material's microstructure with precision? KINTEK's advanced sintering furnaces and consumables provide the exact temperature, atmosphere, and process control you need to achieve optimal density, grain size, and performance for your lab's specific applications—from high-strength components to porous filters. Contact our experts today to discuss how we can optimize your sintering process!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics