In short, extending the sintering time allows for more complete atomic diffusion between particles. This results in a material that is generally denser, stronger, and has larger grains. The process is not infinite; the rate of change slows significantly as the material approaches its theoretical maximum density.

Sintering is fundamentally a process driven by atomic diffusion. Time is the critical window that allows this diffusion to occur, enabling particles to bond, pores to be eliminated, and the material to densify. The key is understanding that time works in tandem with temperature, and its effects are subject to diminishing returns.

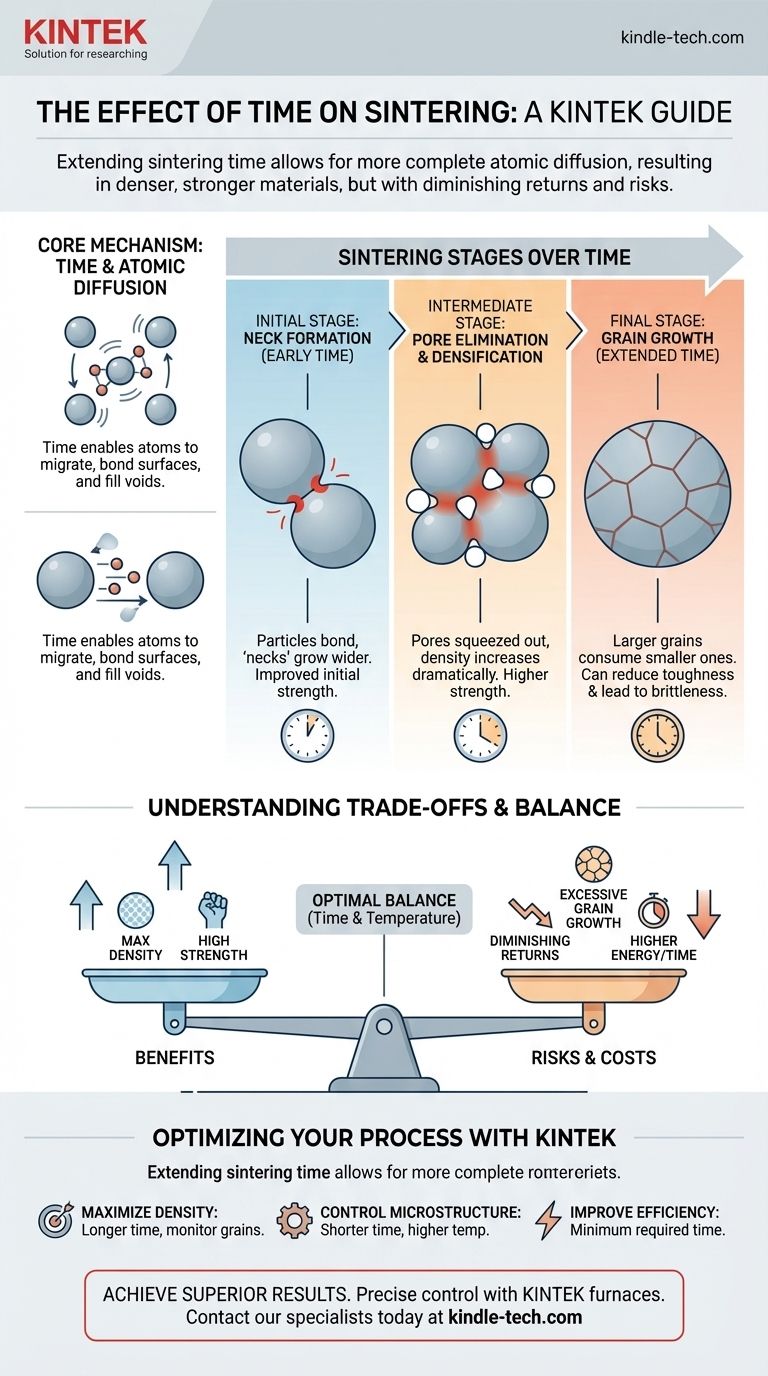

The Fundamental Role of Time in Sintering

To understand the effect of time, you must first understand the mechanism it enables. Sintering transforms a loose powder compact into a solid object by heating it below its melting point. This entire transformation relies on atoms moving between particles.

Sintering is a Diffusion-Dependent Process

Atomic diffusion is the process of atoms migrating from one location to another. This movement is not instantaneous.

It requires both sufficient energy (provided by heat) and sufficient time for atoms to travel, bond particle surfaces, and fill in the voids between them.

Initial Stage: Neck Formation

When sintering begins, the first points of contact between individual particles start to fuse. This initial bonding creates small bridges, or "necks."

The longer the material is held at temperature, the more atoms can diffuse to these contact points, causing the necks to grow wider and stronger.

Intermediate Stage: Pore Elimination and Densification

As the necks between particles grow, they create a powerful force that pulls the particle centers closer together.

This action systematically squeezes out the empty spaces, or pores, that were trapped between the powder particles. With more time, more pores are eliminated, which directly increases the material's overall density.

Final Stage: Grain Growth

Once most of the porosity has been removed, a final process called grain growth begins to dominate. Smaller crystal grains are gradually consumed by larger, more stable ones.

Extended time at sintering temperature directly promotes grain growth. While this can help eliminate the very last remnants of porosity, it also significantly changes the material's microstructure.

Understanding the Trade-offs of Sintering Time

Simply increasing the sintering time is not always the best strategy. The benefits must be weighed against potential negative consequences, revealing a crucial balance between density, microstructure, and process efficiency.

The Point of Diminishing Returns

The rate of densification is fastest in the early and middle stages of sintering. As the material approaches its theoretical maximum density, the process slows dramatically.

Doubling the sintering time at this late stage will yield a very small increase in density, but it will consume significantly more energy and time.

The Risk of Excessive Grain Growth

This is the most critical trade-off. While time is needed to achieve high density, too much time can lead to excessive grain growth.

For many materials, especially advanced ceramics, overly large grains can be detrimental to mechanical properties like strength and fracture toughness, making the final part more brittle.

The Interplay with Temperature

Time and temperature are inextricably linked. The same level of densification can often be achieved with different combinations.

A shorter time at a higher temperature can produce a similar result to a longer time at a lower temperature. The choice depends on the desired final grain size and the material's sensitivity to thermal exposure.

Optimizing Sintering Time for Your Goal

The "correct" sintering time depends entirely on the desired properties of the final component. Your goal determines how you balance the variables.

- If your primary focus is achieving maximum density: You will likely need a longer sintering time, but you must carefully monitor the process to avoid excessive grain growth that could compromise mechanical integrity.

- If your primary focus is controlling grain size for specific mechanical properties: You may need to use a shorter time at a carefully selected higher temperature to achieve the target density without allowing grains to grow too large.

- If your primary focus is process efficiency and cost: The goal is to identify the minimum time required to achieve the necessary specifications, avoiding unnecessary energy consumption and furnace time.

Ultimately, mastering sintering involves treating time not as a simple duration, but as a critical variable to balance against temperature to achieve your desired material structure and performance.

Summary Table:

| Sintering Stage | Key Effect of Extended Time | Impact on Material Properties |

|---|---|---|

| Initial (Neck Formation) | Increased neck growth between particles | Improved initial bond strength |

| Intermediate (Pore Elimination) | Higher densification, reduced porosity | Increased density and strength |

| Final (Grain Growth) | Larger grain size, potential overgrowth | Can reduce strength and toughness |

Achieve the perfect balance of sintering time and temperature for your materials.

Optimizing your sintering process is critical for developing materials with the right density, strength, and microstructure. KINTEK specializes in providing the advanced lab equipment and expert support you need to master this balance.

Our sintering furnaces offer precise control over time and temperature profiles, enabling you to:

- Maximize Density: Achieve near-theoretical density without compromising grain structure.

- Control Microstructure: Prevent excessive grain growth to maintain optimal mechanical properties.

- Improve Process Efficiency: Reduce energy consumption and cycle times while meeting your specifications.

Whether you are working with advanced ceramics, metals, or other powdered materials, KINTEK has the solutions to enhance your R&D and production. Contact our experts today to discuss your specific sintering challenges and how our equipment can help you achieve superior results.

Get in touch with our sintering specialists now!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process