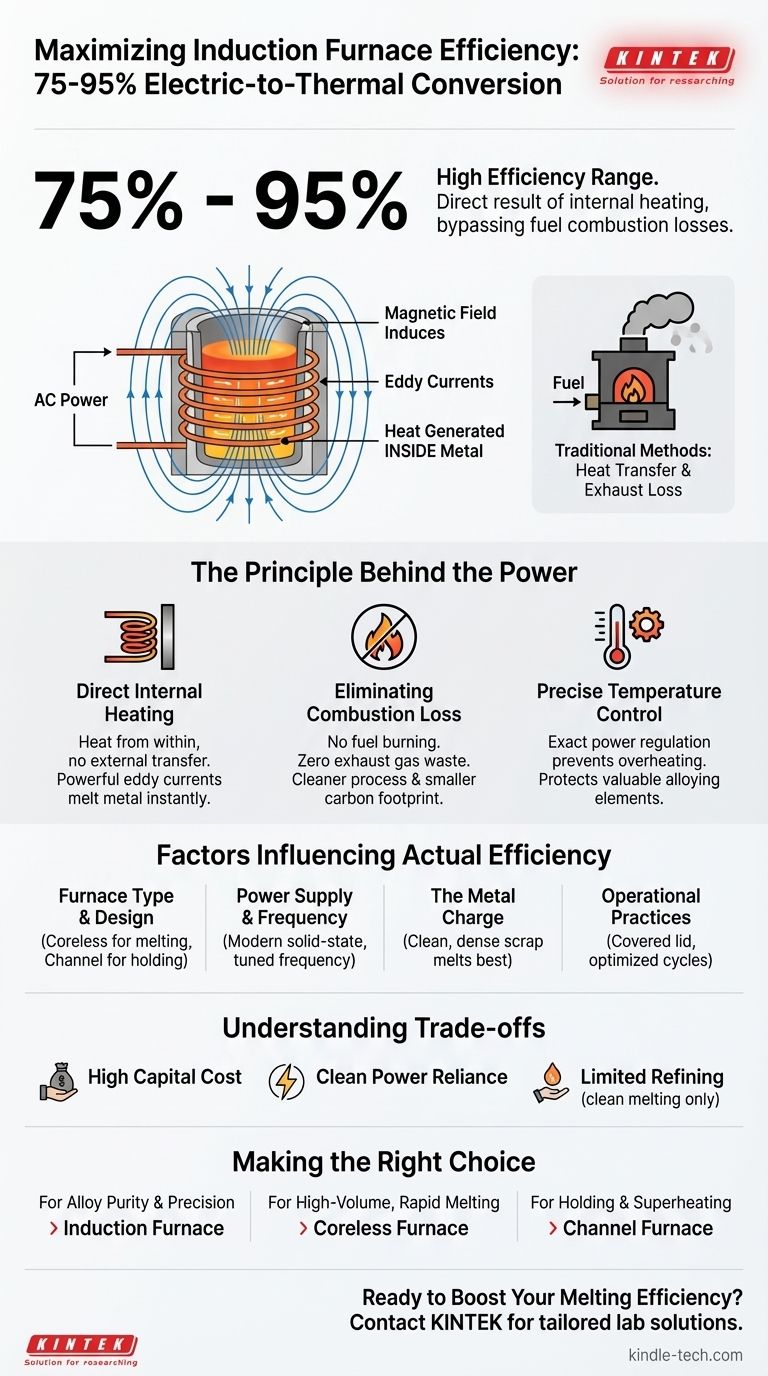

To be precise, the electrical-to-thermal efficiency of a modern induction furnace typically ranges from 75% to 95%. This high efficiency is a direct result of its unique heating mechanism, where heat is generated inside the metal itself, rather than being transferred from an external fuel source. However, this headline figure is influenced by the furnace type, its size, and operational practices.

The core reason for an induction furnace's high efficiency is its principle of direct heating. By inducing an electric current within the metal, it bypasses the massive heat losses associated with fuel combustion, exhaust gases, and heating the furnace structure common in traditional methods.

The Principle Behind Induction Furnace Efficiency

To understand why an induction furnace is so effective, we need to look at how it fundamentally differs from fuel-fired furnaces. Its efficiency isn't just an incremental improvement; it's the result of a completely different approach to generating heat.

Direct Internal Heating

An induction furnace operates like a powerful, specialized transformer. An alternating current passes through a water-cooled copper coil, creating a strong electromagnetic field.

When conductive metal is placed inside this field, the field induces powerful secondary currents, known as eddy currents, directly within the metal charge. The metal's natural electrical resistance causes these currents to generate immense heat, melting it from the inside out.

This is fundamentally more efficient than heating the air or walls of a chamber and waiting for that heat to radiate into the metal.

Eliminating Combustion Loss

Traditional furnaces burn fuel like coke or natural gas. A significant portion of the energy from this combustion is immediately lost as hot exhaust gases going up a flue.

An induction furnace has no combustion. This completely eliminates that primary source of energy waste, contributing to a cleaner working environment and a smaller carbon footprint.

Precise Temperature Control

The power supplied to the induction coil can be regulated with extreme precision. This allows for tight control over the metal's temperature.

This prevents overheating, which not only wastes energy but can also burn off valuable and expensive alloying elements. The ability to hold a specific temperature accurately is a form of process efficiency.

Factors That Influence Actual Efficiency

The 75-95% range is not static. Several factors determine where a specific furnace will perform on that scale.

Furnace Type and Design

There are two main types of induction furnaces: coreless and channel. Coreless furnaces are well-suited for rapidly melting solid scrap and are common in foundries. Channel furnaces, which maintain a loop of molten metal, are exceptionally efficient for holding large volumes of metal at a constant temperature or for superheating.

Power Supply and Frequency

The efficiency of energy transfer depends on the design of the power supply. Modern, solid-state power supplies using large-scale integrated circuits are far more efficient than older technologies.

The frequency of the alternating current is also tuned to the type and amount of metal being melted to maximize energy coupling and heating effectiveness.

The Metal Charge

The physical characteristics of the metal being melted (the "charge") have a significant impact. A densely packed charge of clean, uniform-sized scrap will melt more efficiently than a loose charge of oily, dirty, or oddly shaped material.

Operational Practices

How the furnace is operated day-to-day matters. Keeping the lid on minimizes heat radiation loss, and optimizing charging and pouring cycles reduces the time the furnace spends losing heat while waiting for the next step.

Understanding the Trade-offs

While highly efficient, induction furnaces are not the solution for every application. Their advantages come with specific considerations.

High Initial Capital Cost

The furnace, its advanced power supply, and the necessary water-cooling infrastructure represent a significant upfront investment compared to some simpler fuel-fired alternatives.

Reliance on Clean Power

Induction furnaces are sensitive to the quality and stability of the electrical grid. They require a robust power supply, and fluctuations can disrupt operation.

Limited Refining Capability

The melting process inside an induction furnace is very clean, but it does not refine the metal. Unlike an electric arc furnace, it cannot remove unwanted elements like sulfur and phosphorus. Therefore, the input material must be of high quality and cleanliness.

Making the Right Choice for Your Application

Selecting the right melting technology depends entirely on your primary goal.

- If your primary focus is alloy purity and precise composition: An induction furnace is the superior choice due to its clean, non-contaminating, and highly controllable melting process.

- If your primary focus is high-volume, rapid melting for a foundry: A coreless induction furnace offers an unmatched combination of speed, energy efficiency, and a clean working environment.

- If your primary focus is holding large amounts of molten metal at temperature: A channel induction furnace provides exceptional thermal efficiency for holding and superheating applications.

Ultimately, an induction furnace's efficiency is not just a number, but a direct result of its fundamentally superior method of transferring energy into metal.

Summary Table:

| Factor | Impact on Efficiency |

|---|---|

| Heating Method | Direct internal heating via eddy currents (90-95% efficient) |

| Combustion Losses | Eliminated (no exhaust gases) |

| Temperature Control | Precise regulation prevents overheating waste |

| Furnace Type | Coreless (melting) vs. Channel (holding) have different optimal efficiencies |

| Charge Material | Clean, dense scrap melts more efficiently |

Ready to Boost Your Melting Efficiency?

Choosing the right induction furnace is critical for maximizing energy savings and productivity in your lab or foundry. KINTEK specializes in high-efficiency lab equipment and consumables, providing solutions tailored to your specific melting needs—whether for alloy purity, rapid melting, or precise temperature holding.

Contact our experts today to discuss how our induction furnaces can reduce your energy costs and enhance your process control.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance