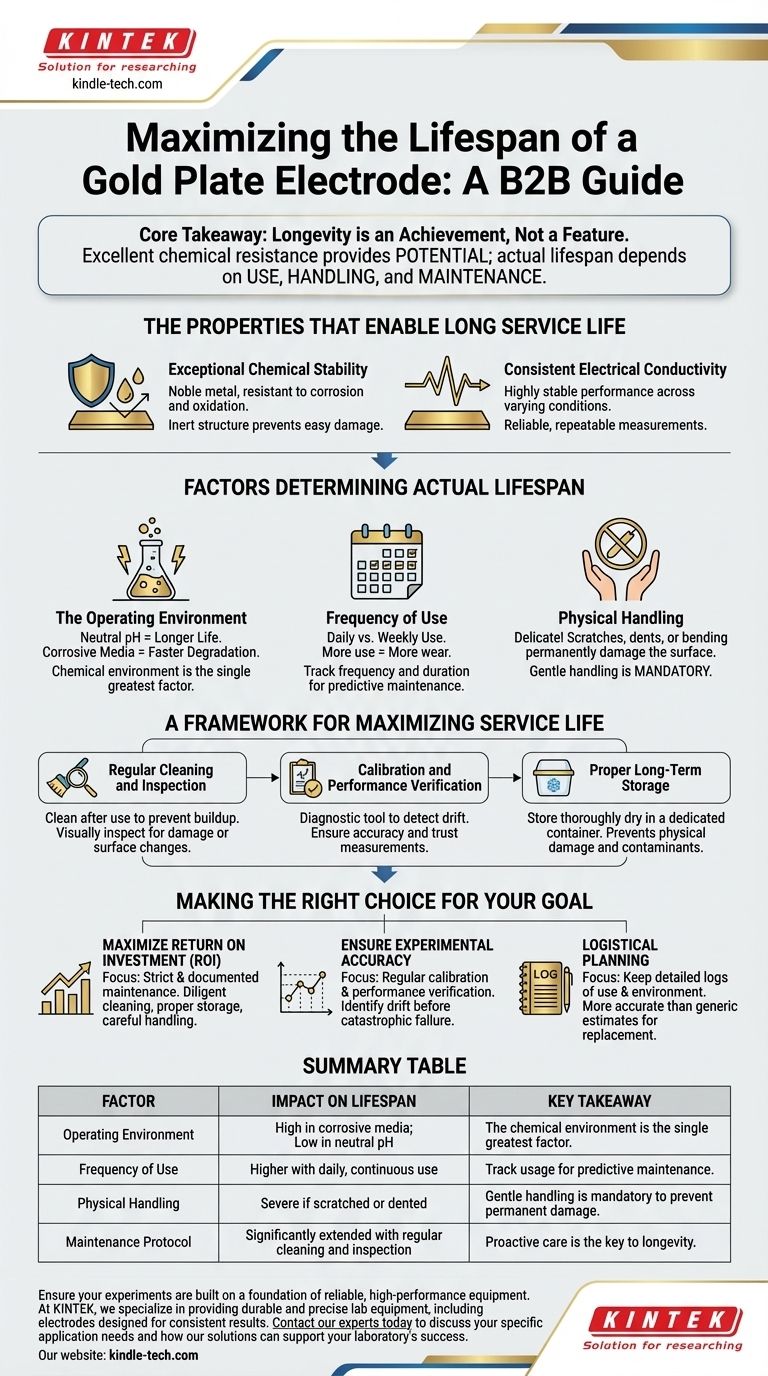

Ultimately, the lifespan of a gold plate electrode is not defined by a fixed number of years or cycles. Instead, it is almost entirely dependent on its specific application, the chemical environment it operates in, and the rigor of its maintenance protocol. With proper care, it is designed for a long service life due to gold's inherent stability.

The core takeaway is that a gold plate electrode's longevity is not a feature you buy, but a result you achieve. Its excellent chemical resistance provides the potential for a long life, but its actual lifespan is determined by how it is used, handled, and maintained.

The Properties That Enable a Long Service Life

A gold plate electrode's potential for longevity stems from the fundamental properties of gold itself. Understanding these characteristics is key to maximizing its use.

Exceptional Chemical Stability

Gold is a noble metal, meaning it has outstanding resistance to corrosion and oxidation. This chemical inertness prevents it from being easily damaged in most electrochemical environments, ensuring the electrode's structure is not compromised over time.

Consistent Electrical Conductivity

The electrode exhibits highly stable electrical conductivity. This performance remains consistent with minimal variation even when subjected to different temperatures or environmental conditions, ensuring reliable and repeatable measurements throughout its life.

Factors That Determine Actual Lifespan

While the material properties provide potential, real-world conditions dictate the actual service life. The phrase "proper use and maintenance" is the most critical variable.

The Operating Environment

An electrode used intermittently in a neutral pH solution will last significantly longer than one used continuously in an aggressive or highly corrosive medium. The specific chemistry of your application is the single greatest factor in its degradation rate.

Frequency of Use

An electrode used daily will naturally experience more wear than one used weekly. Tracking the frequency and duration of use is essential for creating a predictive maintenance schedule.

Physical Handling

The references note that the electrode is delicate. Scratches, dents, or bending can permanently damage the surface, altering its electrochemical properties and leading to failure far sooner than any chemical degradation would. Gentle handling is mandatory.

A Framework for Maximizing Service Life

A proactive maintenance strategy is the most effective way to extend the electrode's lifespan from a theoretical potential to a practical reality.

Regular Cleaning and Inspection

After use, the electrode must be cleaned according to established procedures to prevent the buildup of contaminants that could affect performance. Visual inspection for any signs of physical damage or surface changes is also critical.

Calibration and Performance Verification

Regular calibration against a known standard is not just about ensuring accuracy. It is a diagnostic tool that can reveal a slow degradation in performance, signaling that the electrode may be nearing the end of its reliable life.

Proper Long-Term Storage

For storage, the electrode should be thoroughly dried and placed in a dedicated, protective container. This prevents accidental physical damage and minimizes exposure to airborne contaminants.

Making the Right Choice for Your Goal

Instead of focusing on a fixed lifespan, align your operational strategy with your primary objective.

- If your primary focus is maximizing return on investment: Implement a strict and documented maintenance protocol. Diligent cleaning, proper storage, and careful handling are the most effective ways to extend service life.

- If your primary focus is ensuring experimental accuracy: Prioritize a schedule of regular calibration and performance verification. This allows you to trust your measurements and identify performance drift long before catastrophic failure.

- If your primary focus is logistical planning: Keep detailed logs of use, including the chemical environments and duration of each experiment. This data will provide a far more accurate basis for predicting replacement needs than any generic manufacturer estimate.

By shifting focus from a predetermined expiry date to a proactive management strategy, you can ensure the electrode delivers consistent, reliable performance for as long as possible.

Summary Table:

| Factor | Impact on Lifespan | Key Takeaway |

|---|---|---|

| Operating Environment | High in corrosive media; Low in neutral pH | The chemical environment is the single greatest factor. |

| Frequency of Use | Higher with daily, continuous use | Track usage for predictive maintenance. |

| Physical Handling | Severe if scratched or dented | Gentle handling is mandatory to prevent permanent damage. |

| Maintenance Protocol | Significantly extended with regular cleaning and inspection | Proactive care is the key to longevity. |

Ensure your experiments are built on a foundation of reliable, high-performance equipment.

At KINTEK, we specialize in providing laboratory professionals with durable and precise lab equipment, including electrodes designed for consistent results. Our expertise can help you select the right tools and establish maintenance protocols to maximize your investment and ensure data integrity.

Contact our experts today to discuss your specific application needs and how our solutions can support your laboratory's success.

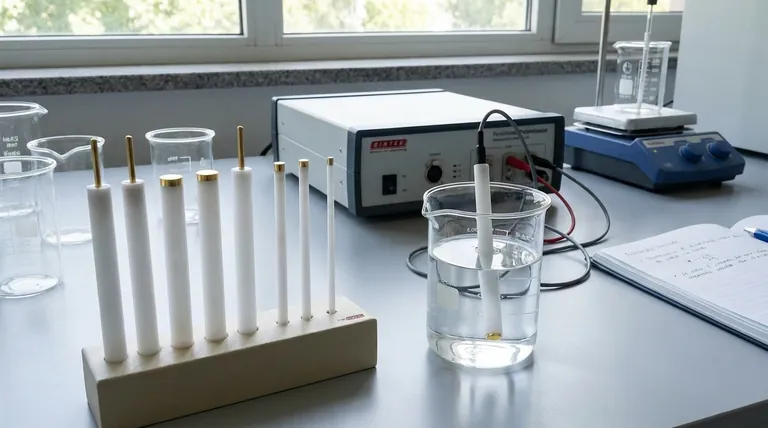

Visual Guide

Related Products

- Gold Disc Electrode

- Gold Electrochemical Sheet Electrode Gold Electrode

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

- Metal Disc Electrode Electrochemical Electrode

People Also Ask

- What are the necessary pre-treatment steps for a platinum disk electrode before an experiment? Achieve Reliable Electrochemical Data

- Why is the physical grinding process prohibited for plated electrodes? Protect Your Gold and Platinum Lab Equipment

- What does the regular maintenance inspection of a carbon fiber brush entail? Ensure Peak Performance and Longevity

- How should a graphite electrode be pre-treated before use? Ensure Reliable Electrochemical Data

- What are the functions of a Saturated Calomel Electrode and a salt bridge in acidic corrosion inhibition experiments?

- What maintenance procedures are required for a glassy carbon electrode? A Step-by-Step Guide to Reliable Performance

- What is the role of platinum electrodes in electrolytic etching? Reveal Precise Stainless Steel Microstructure

- How do three-dimensional metal foam cathodes improve metal electrowinning efficiency? Triple Your Deposition Rates