Ultimately, there is no single, universal factor of safety for a hydraulic press. This value is not a standardized industry number but a specific engineering decision made by the manufacturer for each machine model. It is determined by the quality of materials used for the frame and cylinders, the intended application, and the governing safety regulations of the region where it is sold.

The true safety of a hydraulic press is not defined by a single factor but by a system of overlapping protections. This includes the structural over-engineering of its frame, the hard limits set by its hydraulic pressure relief valves, and the strict operational procedures followed by trained personnel.

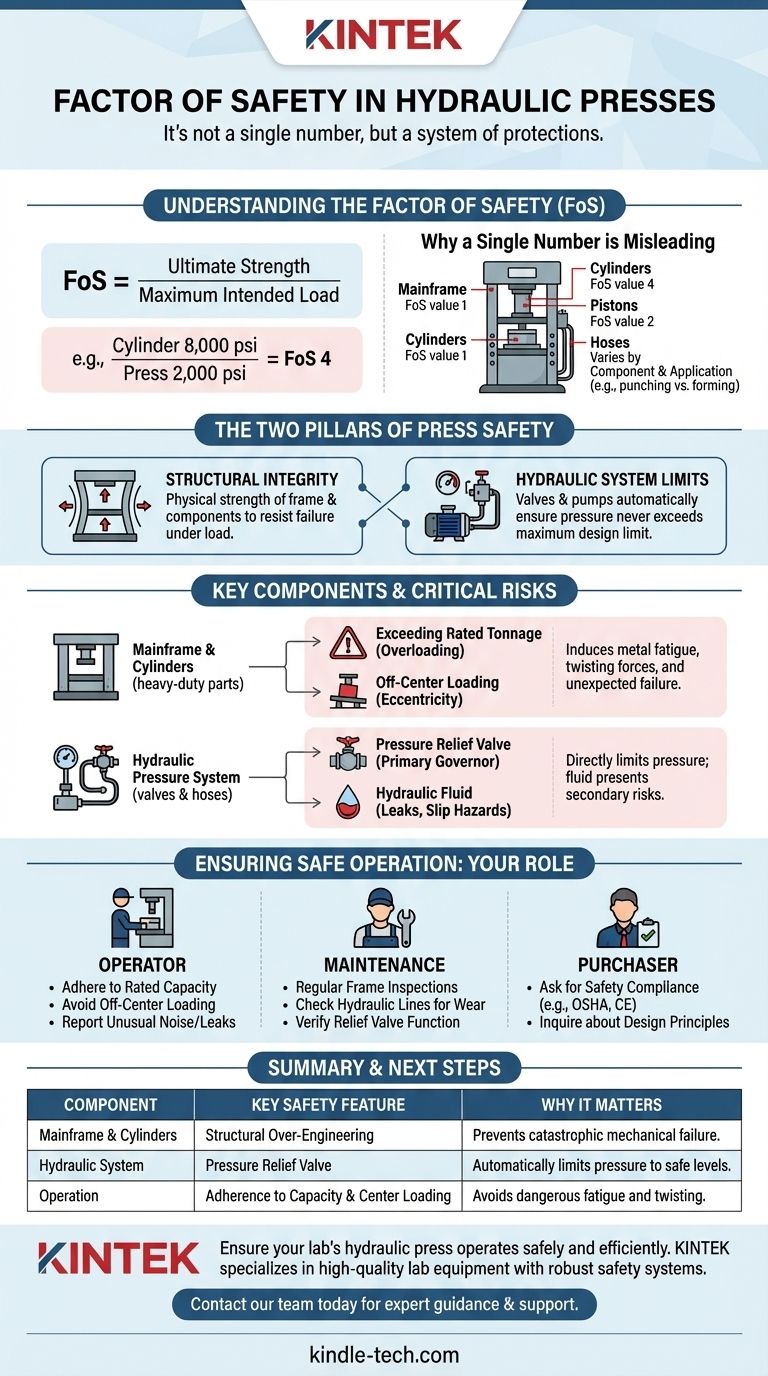

Deconstructing "Factor of Safety" in a Hydraulic Press

To understand why there isn't one answer, we must first clarify what a factor of safety (FoS) truly is and how it applies to a complex machine like a hydraulic press.

What a Factor of Safety Represents

In engineering, the Factor of Safety is a simple ratio: the ultimate strength of a component divided by the maximum intended load it will experience.

For example, if a steel cylinder is designed to withstand 8,000 psi of pressure before bursting and the press is rated to operate at a maximum of 2,000 psi, the FoS for that cylinder is 4 (8,000 / 2,000).

Why a Single Number is Misleading

A hydraulic press is a system of components, not a single part. The FoS can be different for the mainframe, the cylinders, the pistons, and the hydraulic hoses.

Manufacturers calculate these values based on material science, expected wear, and the type of work the press will do. A press designed for rapid punching will require a different safety consideration than one used for slow, gentle forming.

The Two Pillars of Press Safety

Instead of focusing on one number, it's more accurate to think of press safety as a combination of two distinct but related systems:

- Structural Integrity: The physical strength of the frame and components to resist bending, twisting, and breaking under load.

- Hydraulic System Limits: The use of valves and pumps to ensure the hydraulic fluid pressure never exceeds a predetermined maximum.

Key Components That Define Safety Limits

The overall safety of the press is determined by the design and condition of its core parts. The references correctly identify these essential components.

The Mainframe and Cylinders

This is where the structural FoS resides. The mainframe, which holds the material, and the cylinders, which contain the hydraulic fluid and pistons, are heavily over-engineered. They are built to withstand forces far greater than the machine's rated tonnage to prevent catastrophic mechanical failure.

The Hydraulic Pressure System

This system acts as the machine's primary governor. A pressure relief valve is a critical safety component. If the pressure in the system approaches a dangerous level, this valve automatically opens to divert hydraulic fluid back to the tank, preventing the force from exceeding the machine's design limit.

This is a much more direct and reliable safety mechanism than relying solely on the structural FoS of the frame.

The Role of Hydraulic Fluid

As the references note, the fluid itself is a safety consideration. It's the medium that transfers force, but a leak can cause a loss of pressure or create a slip hazard. Furthermore, some hydraulic fluids can be flammable, adding another layer of risk that must be managed.

Understanding the Trade-offs and Risks

A high design FoS from the factory means little if the machine is used improperly or maintained poorly. Understanding the risks is crucial for safe operation.

Exceeding Rated Tonnage

While a press has a built-in FoS, intentionally operating it beyond its rated capacity is dangerous. This practice, known as "overloading," induces metal fatigue and can lead to sudden, unexpected failure of the frame or cylinder over time.

Off-Center Loading (Eccentricity)

This is a critical operational risk. A hydraulic press is designed to have the load applied to the center of the ram. Placing work off-center, as noted in the references as a key safety rule, creates immense twisting forces on the frame and guides.

These forces are not what the machine was engineered to handle and can cause damage or failure even at tonnages well below the machine's rating.

Maintenance and Wear

A factor of safety is calculated for a new machine. Over time, wear and tear degrade components. Worn seals can lead to leaks, old hoses can burst, and microscopic cracks can form in the frame. Regular maintenance is essential to uphold the machine's original safety standards.

How to Ensure Safe Operation

Your approach to safety depends on your role. The goal is to respect the machine's engineered limits and follow established procedures.

- If your primary focus is operating the press: Adhere strictly to the manufacturer's rated capacity and avoid off-center loading. Stop immediately and report any unusual noise, vibration, or leaks.

- If your primary focus is maintenance: Conduct regular inspections of the frame for cracks, check all hydraulic lines for wear or leaks, and verify the correct function of the pressure relief valve.

- If your primary focus is purchasing a press: Ask the manufacturer for documentation on compliance with safety standards (e.g., OSHA, CE) and inquire about the design principles used for the frame and hydraulic system.

True operational safety is an active process, relying on a well-designed machine being used correctly by a knowledgeable operator.

Summary Table:

| Component | Key Safety Feature | Why It Matters |

|---|---|---|

| Mainframe & Cylinders | Structural Over-Engineering | Prevents catastrophic mechanical failure under load. |

| Hydraulic System | Pressure Relief Valve | Automatically limits pressure to prevent exceeding design limits. |

| Operation | Adherence to Rated Capacity & Center Loading | Avoids dangerous metal fatigue and twisting forces. |

Ensure your lab's hydraulic press operates safely and efficiently. KINTEK specializes in high-quality lab equipment, including hydraulic presses designed with robust safety systems. Our experts can help you select the right press for your application and provide guidance on safe operation and maintenance. Contact our team today to discuss your laboratory needs and how we can support your work with reliable, safe equipment.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is the function of a hydraulic forging press? Shape Metal with Unmatched Force and Control

- What are the advantages of a power press? High-Speed, High-Volume Manufacturing Solution

- What makes a hydraulic press so powerful? Unlocking the Physics of Force Multiplication

- What is the function of an ultra-high pressure hydraulic press in ceramic composites? Achieving High-Density Densification

- How does the hydraulic press create a mechanical advantage? Amplify Force with Pascal's Principle

- What damage will be caused by overloading the hydraulic system? Avoid Costly System Failures and Downtime

- What is the ISO standard for XRF analysis? Find the Right Standard for Your Material

- What are some of the problems related to hydraulic power? Manage Leaks, Contamination, and Inefficiency