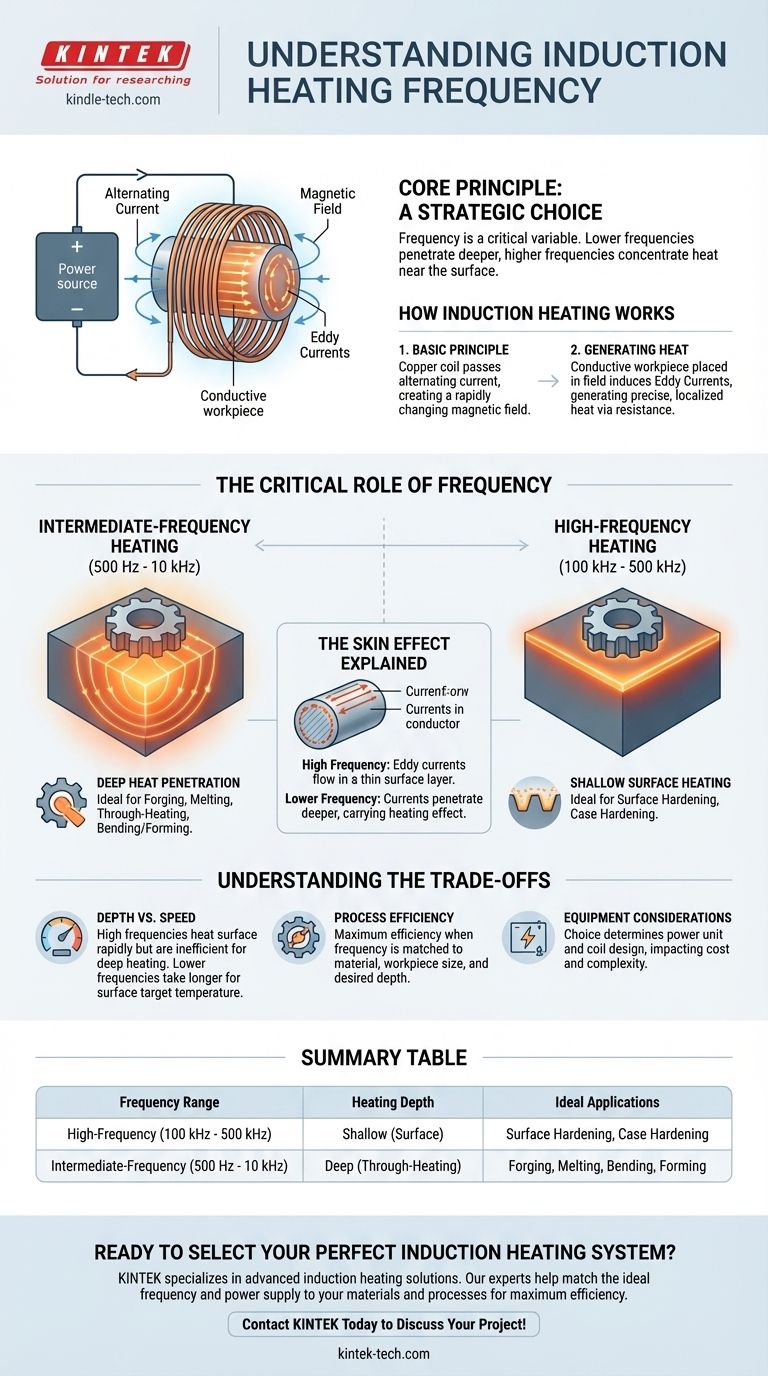

In induction heating, there is no single frequency; instead, the frequency is a critical variable chosen based on the application. Systems are typically categorized into intermediate-frequency, ranging from 500 Hz to 10 kHz, and high-frequency, which operates between 100 kHz and 500 kHz. The selection of a specific frequency directly controls the depth of heat penetration into the workpiece.

The core principle to understand is that frequency selection is a strategic choice. Lower frequencies penetrate deeper into the material, while higher frequencies concentrate the heat near the surface. This relationship is the key to controlling the outcome of the heating process.

How Induction Heating Works

The Basic Principle

An induction heating system uses a copper coil, through which an alternating current is passed. This current generates a rapidly changing magnetic field around the coil.

Generating Heat

When a conductive workpiece is placed within this magnetic field, the field induces electrical currents, known as eddy currents, inside the part. The material's resistance to the flow of these eddy currents generates precise, localized heat without any physical contact.

The Critical Role of Frequency

High-Frequency Heating (100 kHz - 500 kHz)

High-frequency currents are used for applications that require heat to be generated very close to the surface of the part. This is ideal for processes like surface hardening, where you need a hard outer layer while keeping the core of the material ductile.

Intermediate-Frequency Heating (500 Hz - 10 kHz)

Intermediate or medium frequencies are used when deeper heat penetration is necessary. These applications include forging, melting, or through-heating a component before it is bent or formed. The lower frequency allows the magnetic field to penetrate further into the material, generating heat more uniformly throughout its cross-section.

The "Skin Effect" Explained

The reason frequency controls heating depth is a phenomenon called the skin effect. At higher frequencies, the induced eddy currents are forced to flow in a thin layer on the surface of the conductor. As the frequency is lowered, these currents can penetrate deeper into the part, carrying the heating effect with them.

Understanding the Trade-offs

Depth vs. Speed

While high frequencies heat the surface very rapidly, they are inefficient for heating an entire component through to its core. Conversely, a lower frequency that heats deeply may take longer to bring the surface to a target temperature compared to a high-frequency system.

Process Efficiency

Maximum efficiency is achieved when the frequency is properly matched to the material, the size of the workpiece, and the desired heating depth. Using the wrong frequency can lead to wasted energy and inconsistent results, either by not heating deeply enough or by overheating the surface.

Equipment Considerations

High-frequency and intermediate-frequency power supplies are different technologies. The choice of frequency fundamentally determines the type of power unit and coil design required for the system, which has direct implications for equipment cost and complexity.

Selecting the Right Frequency for Your Application

Choosing the correct frequency is essential for achieving the desired metallurgical properties in your workpiece.

- If your primary focus is surface hardening or case hardening: A high-frequency (100 kHz+) system is the correct choice to concentrate energy on the surface.

- If your primary focus is through-heating for forging, forming, or melting: An intermediate-frequency (below 10 kHz) system is required for deep and uniform heat penetration.

- If you are working with small parts or require very shallow heating: You will likely need to operate at the higher end of the frequency spectrum.

Ultimately, understanding frequency transforms induction heating from a simple process into a precisely controlled manufacturing tool.

Summary Table:

| Frequency Range | Heating Depth | Ideal Applications |

|---|---|---|

| High-Frequency (100 kHz - 500 kHz) | Shallow (Surface) | Surface Hardening, Case Hardening |

| Intermediate-Frequency (500 Hz - 10 kHz) | Deep (Through-Heating) | Forging, Melting, Bending, Forming |

Ready to select the perfect induction heating system for your application?

Choosing the right frequency is critical for achieving precise results, whether you need a hardened surface or a uniformly heated component. KINTEK specializes in providing laboratory equipment and consumables, including advanced induction heating solutions tailored to your specific needs.

Our experts will help you match the ideal frequency and power supply to your materials and processes, ensuring maximum efficiency and consistent performance.

Contact KINTEK today to discuss your project and discover how our induction heating systems can enhance your lab's capabilities!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Non Consumable Vacuum Arc Induction Melting Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is the role of an industrial vacuum induction furnace in melting 12% Cr martensitic steel? Pure & Tough Alloys

- What are the advantages of coreless induction furnace? Achieve Clean, Precise, and Efficient Metal Melting

- Can gold be induction heated? Yes, and it's the superior method for high-purity melting.

- What is the efficiency of an aluminum melting furnace? Unlock High Thermal Performance for Your Foundry

- What is the function of vacuum induction melting? Precision Preparation for Ni–20Cr–5Al Model Alloys

- What does induction heating depend on? Master the 4 Key Factors for Precision Heating

- What advantages does gas-blown induction heating (GBIH) offer for titanium nitriding over traditional systems?

- How can we increase the efficiency of induction furnace? Optimize Power, Heat, and Yield for Maximum Performance