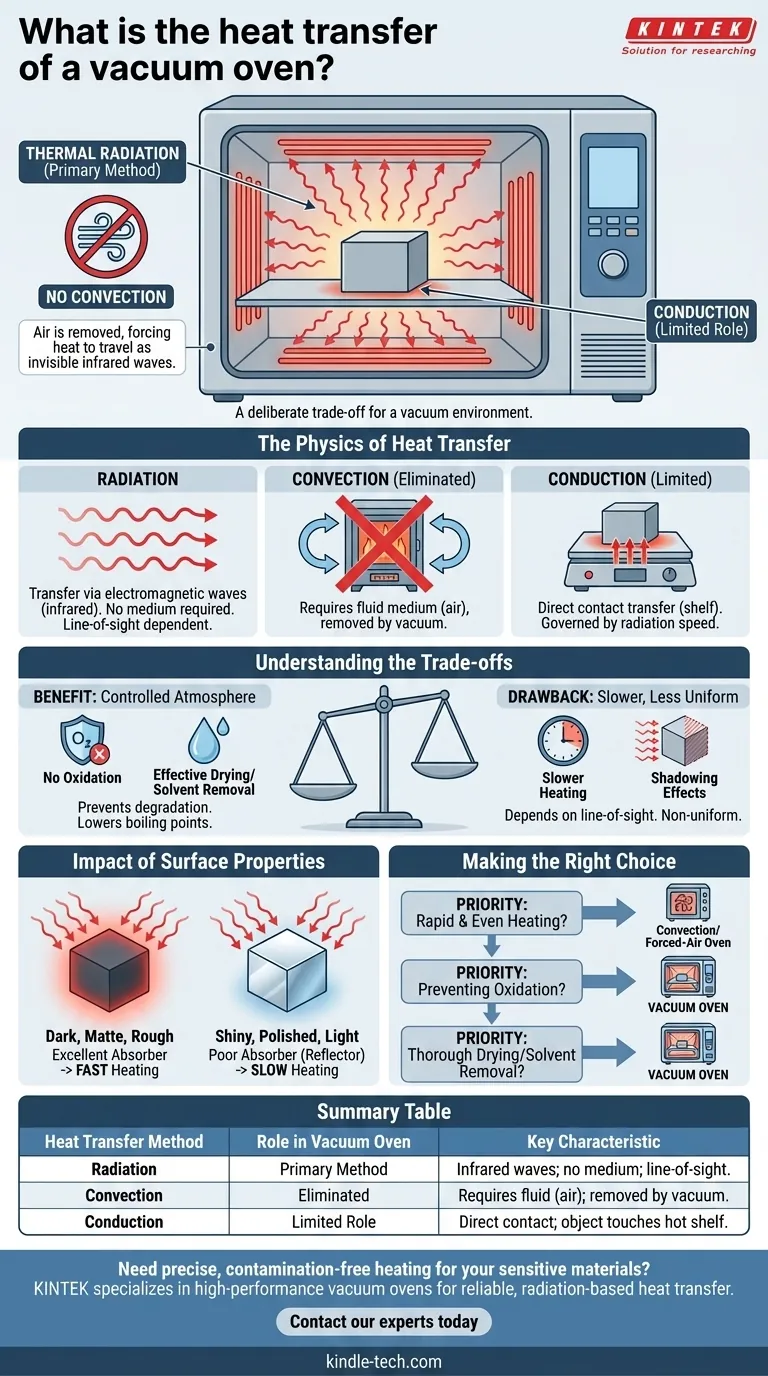

In short, a vacuum oven transfers heat almost exclusively through thermal radiation. Unlike a conventional oven that uses air to circulate warmth, a vacuum oven removes the air, forcing heat to travel as invisible infrared waves from the hot interior walls directly to the object being heated.

The critical takeaway is that removing air fundamentally changes how heat moves. A conventional oven relies on air movement (convection) for fast, even heating, while a vacuum oven depends on the much slower and line-of-sight-dependent process of radiation. This is not a flaw, but a deliberate trade-off to gain the benefits of a vacuum environment.

The Physics of Heat Transfer in a Vacuum

To understand how a vacuum oven works, it's essential to grasp the three ways heat can move. Standard furnaces and ovens use a combination of all three, but a vacuum oven intentionally eliminates one to achieve its purpose.

How Radiation Takes Over

Radiation is the transfer of heat through electromagnetic waves, primarily in the infrared spectrum. It requires no medium to travel. The heating elements and hot inner walls of the oven radiate this energy in all directions, just as the sun radiates heat through the vacuum of space to the Earth. Any object placed inside absorbs this energy, causing its molecules to vibrate faster and its temperature to rise.

Why Convection Disappears

Convection is heat transfer through the movement of fluids (like air or water). In a conventional oven, air is heated, becomes less dense, rises, and circulates, efficiently transferring heat to all surfaces of the object inside. By creating a vacuum, you remove the vast majority of the air, thereby eliminating convection as a significant heat transfer method.

The Limited Role of Conduction

Conduction is heat transfer through direct physical contact. This still occurs in a vacuum oven, but its role is limited. The object will heat up where it touches the hot shelf, and heat will conduct through the object itself. However, because the primary heating mechanism for the shelves is also radiation, the overall process is governed by the speed of radiative heat transfer.

Understanding the Trade-offs

Choosing a vacuum oven means accepting a specific set of advantages and disadvantages driven entirely by its method of heat transfer.

The Benefit: A Controlled Atmosphere

The primary reason for using a vacuum oven is not for heating itself, but for the environment it creates. Removing air prevents oxidation and other chemical reactions that would degrade sensitive materials at high temperatures. It is also exceptionally effective at removing moisture and solvents, as the low pressure drastically reduces their boiling point, allowing them to evaporate quickly and completely.

The Drawback: Slower, Less Uniform Heating

The trade-off for this controlled atmosphere is less efficient heat transfer. Radiation is generally slower than convection. Furthermore, heating can be less uniform because it depends on an object's line-of-sight to the hot surfaces. Areas of an object "shadowed" from the radiating walls will heat much more slowly, relying only on conduction through the material itself.

The Impact of Surface Properties

How well an object heats up in a vacuum oven is highly dependent on its surface.

- Dark, matte, or rough surfaces are excellent at absorbing radiant energy and will heat up relatively quickly.

- Shiny, polished, or light-colored surfaces are poor absorbers (and good reflectors) of radiant energy and will take significantly longer to reach the target temperature.

Making the Right Choice for Your Goal

Selecting the right tool depends entirely on your priority.

- If your primary focus is rapid and even heating: A convection or forced-air oven is far more effective because it uses moving air to quickly transfer heat to all surfaces.

- If your primary focus is preventing oxidation or material degradation: A vacuum oven is the correct choice, as it removes the reactive oxygen that causes these issues during heating.

- If your primary focus is thoroughly drying materials or removing solvents: A vacuum oven is superior because the low pressure accelerates evaporation far beyond what is possible at atmospheric pressure.

By understanding that a vacuum oven heats by radiation, you can leverage its unique atmospheric benefits while properly managing the slower, line-of-sight nature of its heat transfer.

Summary Table:

| Heat Transfer Method | Role in Vacuum Oven | Key Characteristic |

|---|---|---|

| Radiation | Primary Method | Heat transfer via infrared waves; no medium required; line-of-sight dependent. |

| Convection | Eliminated | Requires a fluid medium (air); removed by the vacuum environment. |

| Conduction | Limited Role | Heat transfer through direct contact; occurs where the object touches the hot shelf. |

Need precise, contamination-free heating for your sensitive materials?

KINTEK specializes in high-performance laboratory equipment, including vacuum ovens designed for reliable, radiation-based heat transfer. Our solutions are ideal for applications requiring oxidation prevention, thorough drying, or gentle processing of delicate samples.

Contact our experts today to find the perfect vacuum oven for your laboratory's unique needs and ensure the integrity of your most critical processes.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Benchtop Laboratory Vacuum Freeze Dryer

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is gas nitriding typically conducted in a vacuum resistance heating furnace? Unlock Superior Metal Hardening

- What is the electrical arc in a vacuum? Harnessing Plasma for High-Voltage Tech

- Why is a laboratory vacuum oven necessary for LIPS preparation? Unlock ZIF-8 Pore Activation & Lubricant Infusion

- What is vacuum furnace brazing? Achieve Superior Metal Joining with Unmatched Purity

- What materials are used in calcination? Unlock the Power of Thermal Decomposition

- Which metals cannot be hardened by heat treatment? Understand the limits of thermal hardening.

- What is the rule of thumb for sintering temperature? Achieve the Perfect Balance for Your Materials

- What is plasma arc technology in waste disposal? A Guide to High-Temperature Waste Conversion