The history of the hydraulic press begins with a fundamental principle of physics and a single invention that became a cornerstone of the Industrial Revolution. Invented in 1795 by the English engineer Joseph Bramah, the machine was the first practical application of Pascal's Principle to create an immense, controllable force. This innovation provided a way to shape, mold, and compress materials with a power that was previously unimaginable.

The invention of the hydraulic press was not merely the creation of a new tool; it was the physical embodiment of a scientific law. This transformation of a fluid mechanics principle into industrial power fundamentally changed manufacturing and engineering forever.

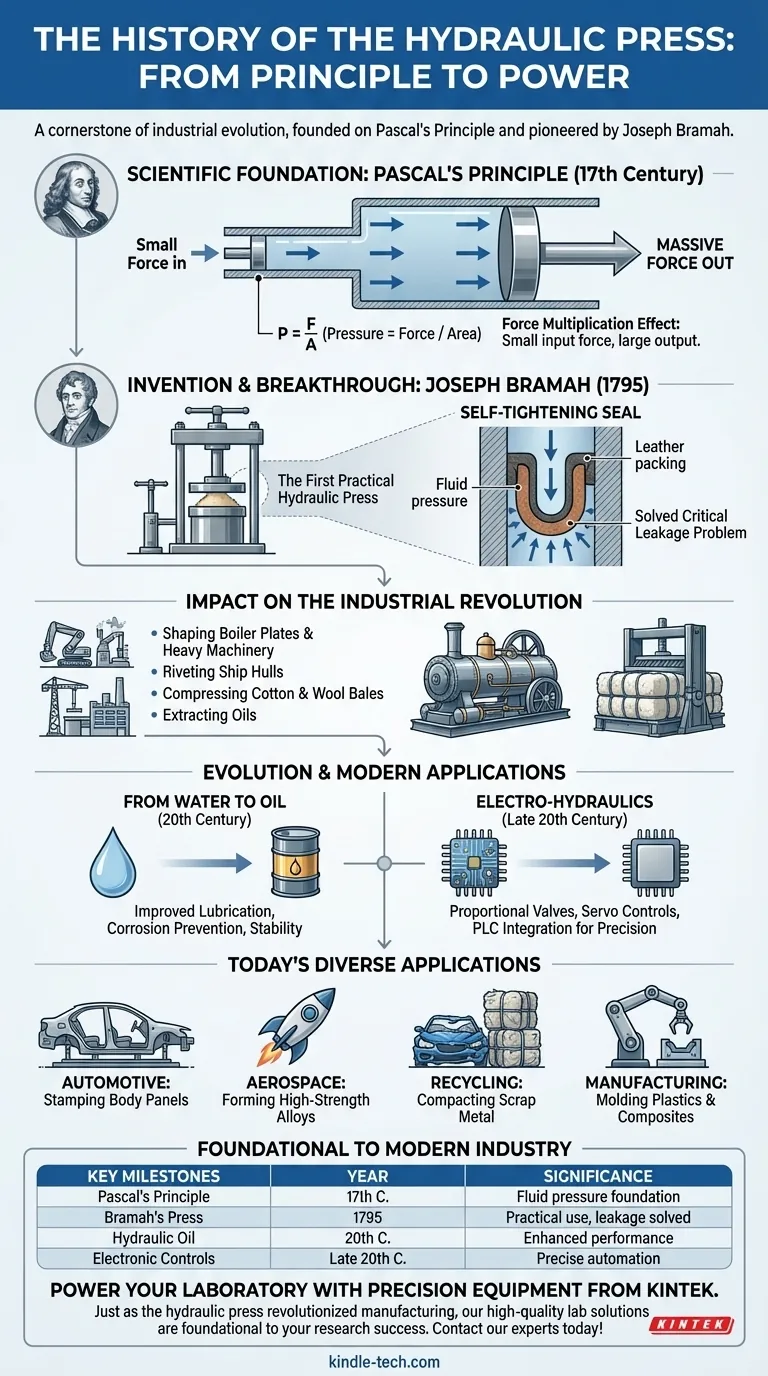

The Scientific Foundation: Pascal's Principle

The Core Concept

The entire operation of a hydraulic press is based on Pascal's Principle. This law, formulated by the French mathematician Blaise Pascal in the 17th century, states that pressure applied to an enclosed, incompressible fluid is transmitted equally to every portion of the fluid and the walls of the containing vessel.

The Force Multiplication Effect

In simple terms, this principle allows for force multiplication. A small amount of force applied to a small piston creates pressure in the hydraulic fluid. Because this pressure is distributed equally throughout the fluid, it pushes with the same force per square inch on a much larger piston, resulting in a massive increase in the total output force.

This is the essential mechanical advantage that makes the hydraulic press so powerful.

The Inventor and the Invention

Joseph Bramah's Breakthrough (1795)

While Pascal laid the theoretical groundwork, it was Joseph Bramah who harnessed it. An accomplished inventor and locksmith, Bramah saw the potential for applying fluid pressure to industrial tasks. His 1795 patent for the "Bramah Press" marked the birth of practical hydraulics.

Solving a Critical Problem

Previous attempts to build such a device had failed due to one persistent issue: leakage. The immense pressures required would force the fluid out of any existing seals.

Bramah's true genius was in his design of a self-tightening seal. He created a U-shaped leather packing that used the fluid pressure itself to press the seal's edges more tightly against the cylinder wall. The higher the pressure, the tighter the seal became, elegantly solving the leakage problem.

The Impact on the Industrial Revolution

A New Era of Manufacturing

The hydraulic press arrived at a pivotal moment. The Industrial Revolution demanded machines capable of working with iron and steel on a massive scale. Bramah's invention provided the "muscle" that was needed.

Powering Heavy Industry

Early presses were instrumental in shaping boiler plates for steam engines, forging heavy machinery parts, and riveting the iron hulls of ships. They could stamp, bend, and form metal with a precision and power that human or animal labor could never match.

Beyond Metalworking

The press's utility quickly expanded beyond metallurgy. It was used to compress cotton and wool into dense bales for shipping, extract oils from seeds, and later, to mold rubber and early plastics under heat and pressure.

Evolution and Modern Applications

From Water to Oil

The first hydraulic presses used water as the working fluid. Over time, industry shifted to specialized hydraulic oil, which offered superior lubrication, prevented corrosion, and had a more stable viscosity across different temperatures.

The Rise of Electro-Hydraulics

The 20th century saw the integration of sophisticated electronics with hydraulic systems. Proportional valves, servo controls, and computer-based controllers (PLCs) now allow for incredibly precise and automated control over the force, speed, and position of the press.

Today's Diverse Applications

The fundamental principle remains unchanged, but the applications are vast. Modern hydraulic presses are essential in nearly every major industry, used for:

- Automotive: Stamping body panels, frames, and engine components.

- Aerospace: Forming high-strength, complex alloy parts.

- Recycling: Compacting scrap metal, plastics, and paper into dense bales.

- Manufacturing: Molding plastic and composite parts, punching, and assembly operations.

Why the Hydraulic Press Remains Foundational

The history of the hydraulic press is a direct line from a scientific idea to a world-changing technology. Understanding its legacy is key to appreciating modern engineering.

- If your primary focus is mechanical engineering: The hydraulic press is the definitive real-world application of Pascal's Principle and the power of fluid mechanics.

- If your primary focus is industrial history: Its invention was a key catalyst of the Industrial Revolution, providing the immense force needed for mass production in heavy industry.

- If your primary focus is modern manufacturing: The core principle is timeless, but its evolution with advanced controls demonstrates the power of integrating foundational physics with automation.

From its simple 18th-century origins, the hydraulic press remains a cornerstone of modern industry, a testament to the immense power of a fundamental physical law.

Summary Table:

| Key Milestone | Year | Key Figure | Significance |

|---|---|---|---|

| Pascal's Principle Formulated | 17th Century | Blaise Pascal | Established the scientific foundation of fluid pressure transmission. |

| First Practical Hydraulic Press Invented | 1795 | Joseph Bramah | Solved the leakage problem with a self-tightening seal, enabling practical use. |

| Shift to Hydraulic Oil | 20th Century | Industry-wide | Improved lubrication, corrosion prevention, and temperature stability. |

| Integration of Electronic Controls | Late 20th Century | Industry-wide | Enabled precise, automated control over force, speed, and position. |

Power Your Laboratory with Precision Equipment from KINTEK

Just as the hydraulic press revolutionized manufacturing, the right lab equipment is foundational to your research and development success. KINTEK specializes in providing high-quality laboratory equipment and consumables that deliver the reliability, precision, and power your work demands.

Whether you are shaping new materials, testing compounds, or developing innovative products, our solutions are designed to enhance your efficiency and accuracy.

Contact our experts today to discuss how KINTEK can meet your specific laboratory needs and help you achieve your goals.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy