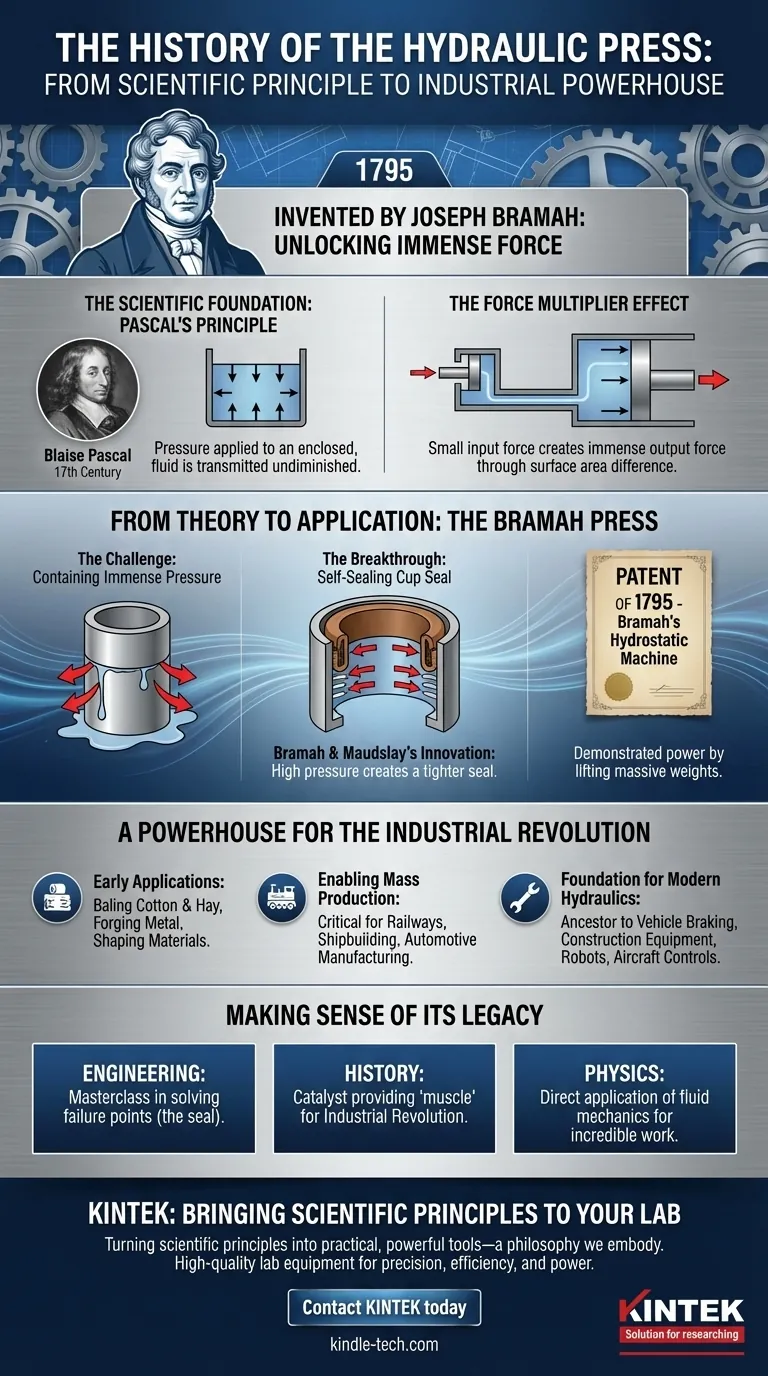

The modern hydraulic press was invented by Joseph Bramah in 1795. Building upon a scientific principle discovered over a century earlier, Bramah’s design solved a critical engineering challenge that unlocked the ability to multiply small inputs of force into immense outputs. This invention became a powerhouse of the Industrial Revolution, fundamentally changing manufacturing and engineering forever.

The history of the hydraulic press is not just about a machine, but about the translation of a fundamental law of physics into a practical tool. Its creation hinged on solving a single, critical problem: how to contain immense pressure.

The Scientific Foundation: Pascal's Principle

A Principle of Pressure

The story begins not with an inventor, but with a physicist: Blaise Pascal. In the 17th century, Pascal formulated the principle that now bears his name.

Pascal's Principle states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

The Force Multiplier Effect

This principle enables force multiplication. Imagine two connected cylinders, one with a small piston and one with a large piston.

If you apply a small force to the small piston, it creates pressure in the fluid. That same pressure acts on the large piston. Because the large piston has a much bigger surface area, the resulting force exerted by it is proportionally larger. This is the core concept that makes a hydraulic press possible.

From Theory to Application: The Bramah Press

The Inventor: Joseph Bramah

While Pascal provided the theory, it was English inventor and locksmith Joseph Bramah who brought it to life. A prolific inventor, Bramah recognized the potential of Pascal's Principle for practical work.

The Challenge of Sealing

The primary obstacle was not the concept, but the execution. Early designs failed because no available seal could withstand the immense internal pressures required. The fluid would simply leak out, rendering the machine useless.

The Breakthrough: The Self-Sealing Cup Seal

Bramah's genius, with assistance from his employee Henry Maudslay, was in creating a self-sealing leather cup seal. This U-shaped seal was designed so that the high-pressure fluid would get inside the cup, forcing the outer edges of the seal against the cylinder wall.

The higher the pressure, the tighter the seal became. This elegant solution used the problem (high pressure) to create the solution (a perfect seal).

The Patent of 1795

With the sealing problem solved, Bramah successfully patented his "hydrostatic machine" or Bramah Press in 1795. He publicly demonstrated his press by lifting massive weights and bending thick iron bars with minimal human effort, proving its immense power.

Understanding the Impact

A Powerhouse for the Industrial Revolution

The hydraulic press arrived at the perfect moment. It quickly replaced less efficient and weaker screw presses and hammers in workshops across Britain.

Its initial applications included pressing hay and cotton into dense bales for shipping, forging metal parts, and shaping materials with a level of force and precision that was previously unimaginable.

Enabling Mass Production

The ability to cold-form large sheets of metal and consistently stamp out identical parts was a critical enabler of mass production. Industries like railway construction, shipbuilding, and later, automotive manufacturing, relied heavily on the power of hydraulic presses.

A Foundation for Modern Hydraulics

The Bramah Press was the direct ancestor of all modern hydraulic systems. The principles of using a sealed, pressurized fluid to transmit force are now used in everything from vehicle braking systems and construction equipment to aircraft flight controls and industrial robots.

Making Sense of its Legacy

The history of the hydraulic press teaches a valuable lesson about the relationship between science, engineering, and innovation. Here is how to contextualize its importance based on your focus:

- If your primary focus is engineering: Recognize the Bramah press as a masterclass in solving a critical failure point (the seal) to unlock the full potential of a physical principle.

- If your primary focus is history: View the hydraulic press not merely as an invention, but as a key catalyst that provided the "muscle" for the Industrial Revolution's greatest achievements.

- If your primary focus is physics: See the press as the most direct and powerful application of Pascal's Principle, perfectly demonstrating how fluid mechanics can be harnessed to achieve incredible work.

Ultimately, this 18th-century invention was a triumph of applied science that continues to shape the world we build today.

Summary Table:

| Key Event | Year | Key Figure | Significance |

|---|---|---|---|

| Pascal's Principle | 17th Century | Blaise Pascal | Established the scientific foundation of fluid pressure transmission. |

| Invention of the Press | 1795 | Joseph Bramah | Solved the critical sealing problem, creating the first practical hydraulic press. |

| Key Innovation | 1795 | Bramah & Maudslay | Developed the self-sealing cup seal, enabling high-pressure operation. |

| Industrial Impact | 19th Century | - | Became a cornerstone of mass production in metalworking and manufacturing. |

Need reliable, powerful equipment for your laboratory or manufacturing processes?

The story of the hydraulic press is one of turning scientific principles into practical, powerful tools—a philosophy we embody at KINTEK. Just as Bramah's press revolutionized industry, our high-quality lab equipment and consumables are designed to bring precision, efficiency, and power to your work.

Whether you require robust presses, reliable ovens, or essential lab supplies, KINTEK specializes in serving your laboratory needs. Let us help you build the future.

Contact KINTEK today to discuss how our solutions can enhance your operations.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.