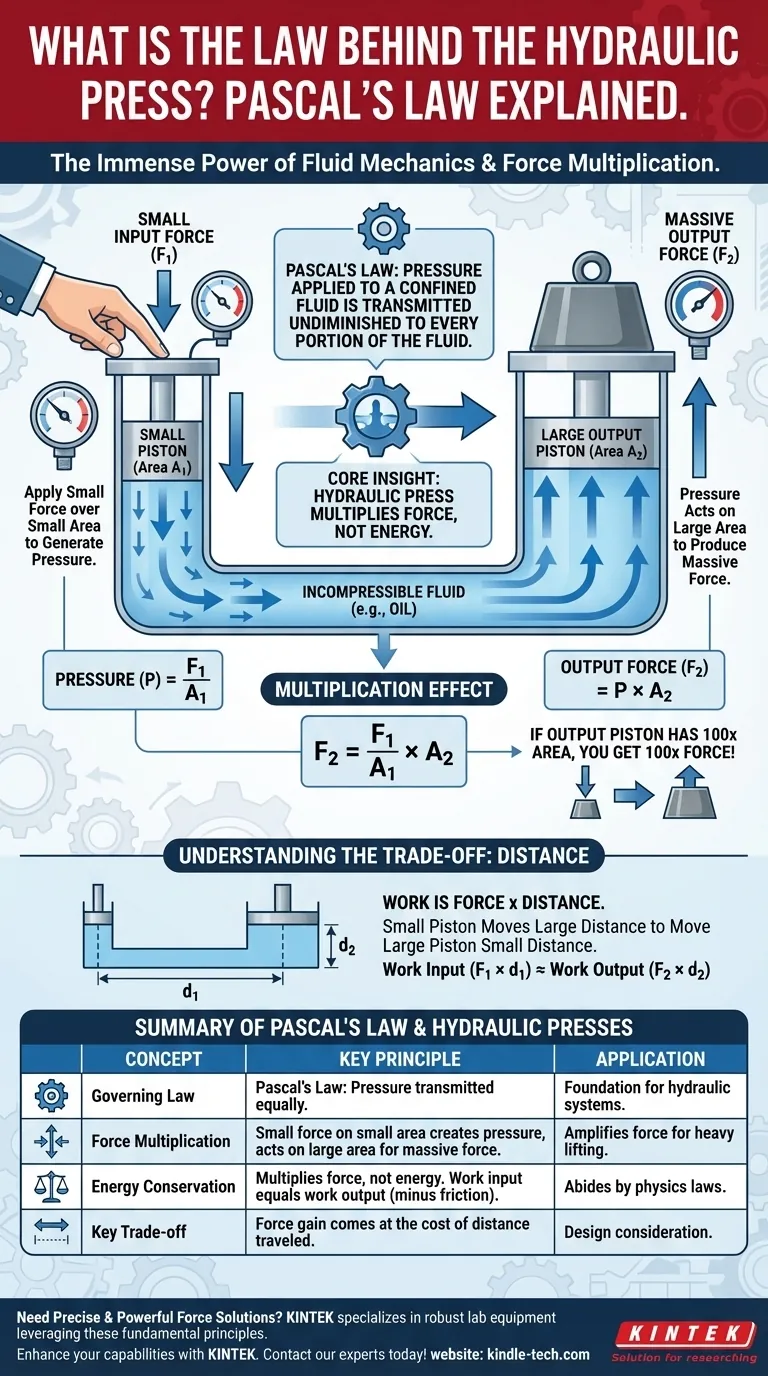

The immense power of a hydraulic press is governed by a fundamental principle of fluid mechanics known as Pascal's Law. This law states that any pressure applied to the surface of a confined, incompressible fluid is transmitted undiminished to every portion of the fluid. This simple concept is what allows a small force applied to one point to be converted into a vastly larger force at another.

The core insight is that a hydraulic press does not create energy, but rather multiplies force. It achieves this by applying a small input force over a small area to generate pressure, which then acts on a much larger area to produce a massive, work-performing output force.

Deconstructing Pascal's Law

To truly grasp how a hydraulic press works, it's essential to understand the difference between force and pressure and how a fluid acts as the medium for their transfer.

Pressure vs. Force

Force is a direct push or pull on an object. Pressure, however, is that force distributed over a specific area.

The formula is simple: Pressure = Force / Area. This distinction is the absolute key to the entire hydraulic system.

The Role of an Incompressible Fluid

Hydraulic systems use a liquid (typically oil) because it is nearly incompressible.

This means that when you apply pressure, the fluid doesn't just get squeezed into a smaller volume. Instead, it efficiently transmits that pressure to every other part of the container.

Transmitting Pressure Equally

According to Pascal's Law, if you increase the pressure by 10 PSI (pounds per square inch) at one point in a sealed hydraulic system, the pressure will increase by exactly 10 PSI everywhere else in that system, regardless of the container's shape.

How Force Multiplication Actually Happens

The genius of the hydraulic press lies in its mechanical design, which consists of two pistons of different sizes connected by a cylinder filled with fluid.

The Two-Piston System

Imagine a small piston, which we'll call the input piston, and a much larger piston, the output piston.

A small force is applied to the input piston, and the resulting work is performed by the large output piston.

The Input Side (Small Piston)

When you apply a small force (F₁) to the input piston with its small area (A₁), you generate a specific amount of pressure in the fluid.

This pressure is calculated as P = F₁ / A₁.

The Output Side (Large Piston)

This exact same pressure (P) is transmitted throughout the fluid and now pushes up on the bottom of the large output piston, which has a much larger area (A₂).

The resulting output force (F₂) is this pressure multiplied by the larger area: F₂ = P * A₂.

The Multiplication Effect

By substituting the first equation into the second, we see the magic: F₂ = (F₁ / A₁) * A₂.

Since the area of the output piston (A₂) is much larger than the area of the input piston (A₁), the output force (F₂) will be proportionally much greater than the input force (F₁). If the output piston has 100 times the area, you get 100 times the force.

Understanding the Trade-offs

This principle may seem like getting something for nothing, but it operates in perfect compliance with the laws of physics, specifically the conservation of energy.

No Free Energy

A hydraulic press multiplies force, but it cannot multiply or create energy. The work done on the system must equal the work performed by the system (ignoring minor losses from friction).

The Distance Trade-off

The trade-off for force multiplication is distance. Work is defined as Force x Distance.

To lift the large output piston by just one inch, the small input piston must travel a much greater distance. The work done (F₁ x d₁) on the input side equals the work done (F₂ x d₂) on the output side. This is the price paid for amplifying the force.

Applying This Principle

Understanding the core concepts allows you to see why hydraulic systems are so fundamental to modern machinery.

- If your primary focus is the core law: The system is governed by Pascal's Law, which states that pressure in a confined fluid is transmitted equally and undiminished.

- If your primary focus is the mechanism: A small force on a small piston creates pressure, and that same pressure acting on a large piston generates a massive, multiplied output force.

- If your primary focus is the limitation: The significant multiplication of force comes at the direct cost of distance; the small piston must move much farther to move the large piston a small amount.

By manipulating the relationship between force, pressure, and area, Pascal's Law provides a foundational principle for modern engineering and force amplification.

Summary Table:

| Concept | Key Principle |

|---|---|

| Governing Law | Pascal's Law: Pressure in a confined fluid is transmitted equally and undiminished. |

| Force Multiplication | A small input force on a small area creates pressure, which acts on a larger area to produce a massive output force. |

| Key Trade-off | Force is multiplied, but the input piston must travel a much greater distance than the output piston moves. |

| Energy Conservation | The system multiplies force, not energy; work input equals work output (minus friction). |

Need precise and powerful force for your lab or production process?

The principles of Pascal's Law are at the heart of reliable hydraulic equipment. At KINTEK, we specialize in supplying robust lab equipment and consumables that leverage these fundamental engineering concepts for accuracy and efficiency. Whether you need custom hydraulic solutions or standard laboratory apparatus, our expertise ensures you get the right tool for the job.

Enhance your capabilities with equipment designed for performance and durability. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples