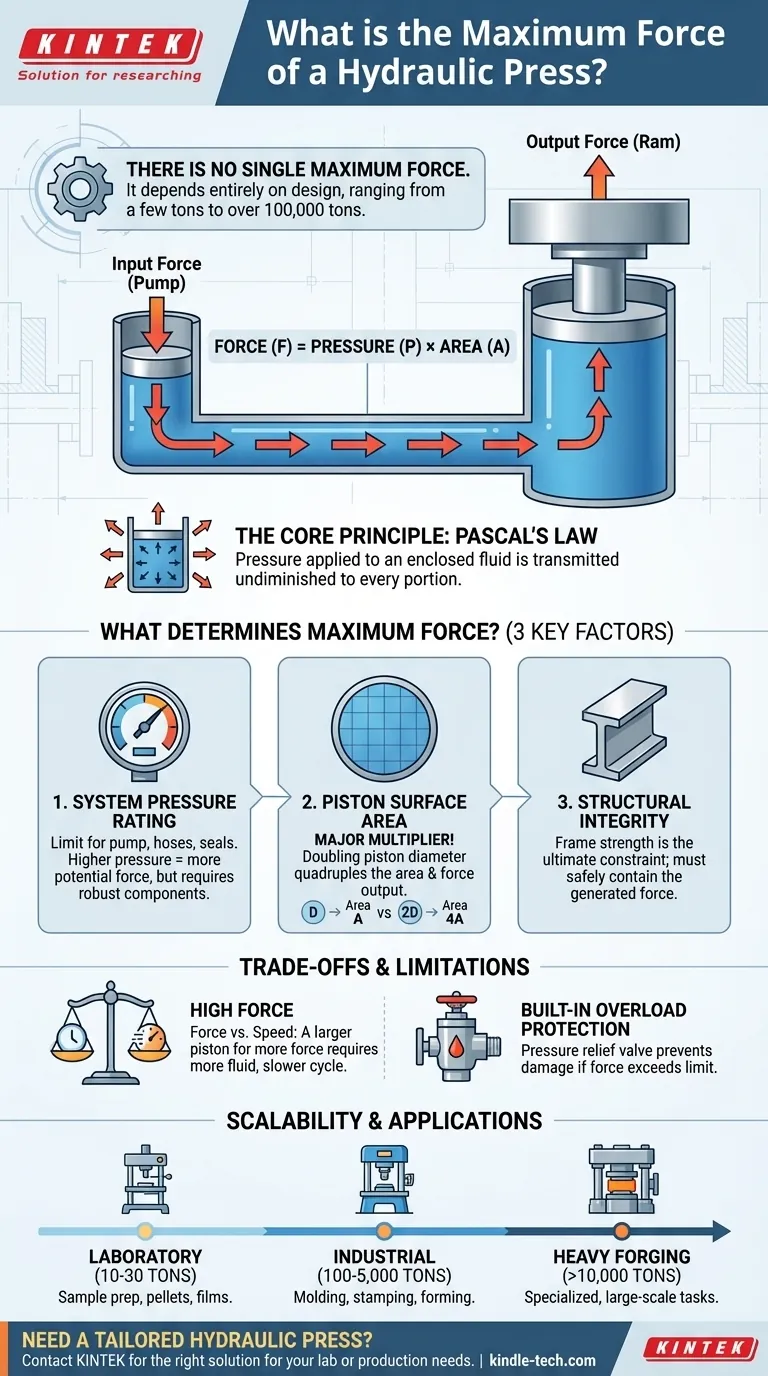

There is no single maximum force for a hydraulic press. Instead, the force a press can generate is determined entirely by its design, ranging from small benchtop units producing a few tons of force to massive industrial machines capable of exerting over 100,000 tons. The immense power of a hydraulic press comes from a simple principle: multiplying a small amount of pressure into a massive amount of force.

The core concept to understand is that the maximum force of any hydraulic press is a direct product of two factors: the pressure of the hydraulic fluid and the surface area of the piston it pushes against. Its ultimate limit is not a universal constant but a specific engineering and structural constraint.

How a Hydraulic Press Generates Force

A hydraulic press operates on a fundamental principle of fluid dynamics, allowing it to convert a small input force into a massive output force with relatively few moving parts.

The Core Principle: Pascal's Law

The entire system works because of Pascal's Law. This law states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simpler terms, any pressure created by the pump is applied equally across the entire system.

The Key Components

A basic hydraulic press consists of a few essential parts mentioned in the references:

- A Pump: This creates the initial flow and pressure in the hydraulic fluid (typically oil).

- Hydraulic Cylinders: The system uses two interconnected cylinders of different sizes. The smaller one is often called the plunger, and the larger one is the ram.

- A Piston: Located inside the main cylinder (the ram), this is the component that moves to press the object.

- A Frame: This rigid structure holds all components and must withstand the immense forces being generated.

The Force Multiplication Formula

The "magic" of the hydraulic press happens at the piston. The force it exerts is calculated with a simple formula: Force = Pressure × Area.

Because the pressure is consistent throughout the fluid, a large piston surface area will multiply that pressure into a huge output force. This is how a small pump can power a machine that crushes metal.

What Determines a Press's Maximum Force?

The theoretical maximum force is a function of the system's design parameters. Three primary factors define this limit.

System Pressure Rating

The hydraulic pump and all associated hoses and seals are rated for a maximum operating pressure. Pushing beyond this limit risks catastrophic failure. Higher-pressure systems can generate more force but require more robust and expensive components.

Piston Surface Area

This is the most significant force multiplier. Doubling the diameter of the main piston (the ram) quadruples its surface area, and therefore quadruples the potential output force for the same amount of fluid pressure. The largest industrial presses have enormous pistons.

Structural Integrity

The frame of the press must be able to safely contain the force being generated. The maximum force rating is as much about the strength of the steel frame as it is about the hydraulic system itself. This is often the ultimate limiting factor.

Understanding the Trade-offs and Limitations

While capable of immense force, hydraulic presses are not without their operational constraints. Understanding these trade-offs is key to appreciating their design.

Force vs. Speed

There is a direct trade-off between force and speed. A very large piston requires a massive volume of hydraulic fluid to move it. This means that extremely high-force presses are often relatively slow to complete a full cycle.

Built-in Overload Protection

A key advantage is their inherent overload protection. Unlike a mechanical press that can break if overloaded, a hydraulic press uses a pressure relief valve. If the force exceeds the design limit, the valve opens, preventing damage to the machine.

Complexity and Maintenance

While the design is simple in principle, high-pressure hydraulic systems require careful maintenance. Leaks in seals or hoses can reduce efficiency and create safety hazards. The hydraulic fluid must also be kept clean to prevent damage to the pump and valves.

How to Apply This to Your Goal

The "maximum force" you need is entirely dependent on your application. The focus should be on matching the press's tonnage to the task at hand.

- If your primary focus is laboratory sample preparation: A small benchtop press with a capacity of 10-30 tons is typically more than sufficient for creating pellets or films.

- If your primary focus is industrial manufacturing (molding, stamping, forming): You will need a press specifically designed for your material and part size, likely in the range of 100 to 5,000 tons.

- If your primary focus is heavy forging or extrusion: You are in the realm of highly specialized, often custom-built presses that can exceed 10,000 tons of force.

Ultimately, the power of a hydraulic press lies in its elegant use of fluid pressure to create a scalable and controllable force for nearly any application.

Summary Table:

| Key Factor | Role in Determining Maximum Force |

|---|---|

| System Pressure Rating | Defines the hydraulic fluid pressure limit; higher pressure enables greater force but requires robust components. |

| Piston Surface Area | Acts as the primary force multiplier; larger area significantly increases output force for the same pressure. |

| Structural Integrity | The frame must withstand generated forces; often the ultimate constraint on a press's maximum capacity. |

Need a Hydraulic Press Tailored to Your Specific Force Requirements?

Whether you're preparing laboratory samples or tackling large-scale industrial forming, KINTEK's expertise in lab equipment ensures you get the right press for your task. From benchtop models for precise pellet preparation to heavy-duty systems for manufacturing, we provide reliable solutions that match your force, speed, and safety needs.

Contact KINTEK today to discuss your application and find the perfect hydraulic press for your laboratory or production environment!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy