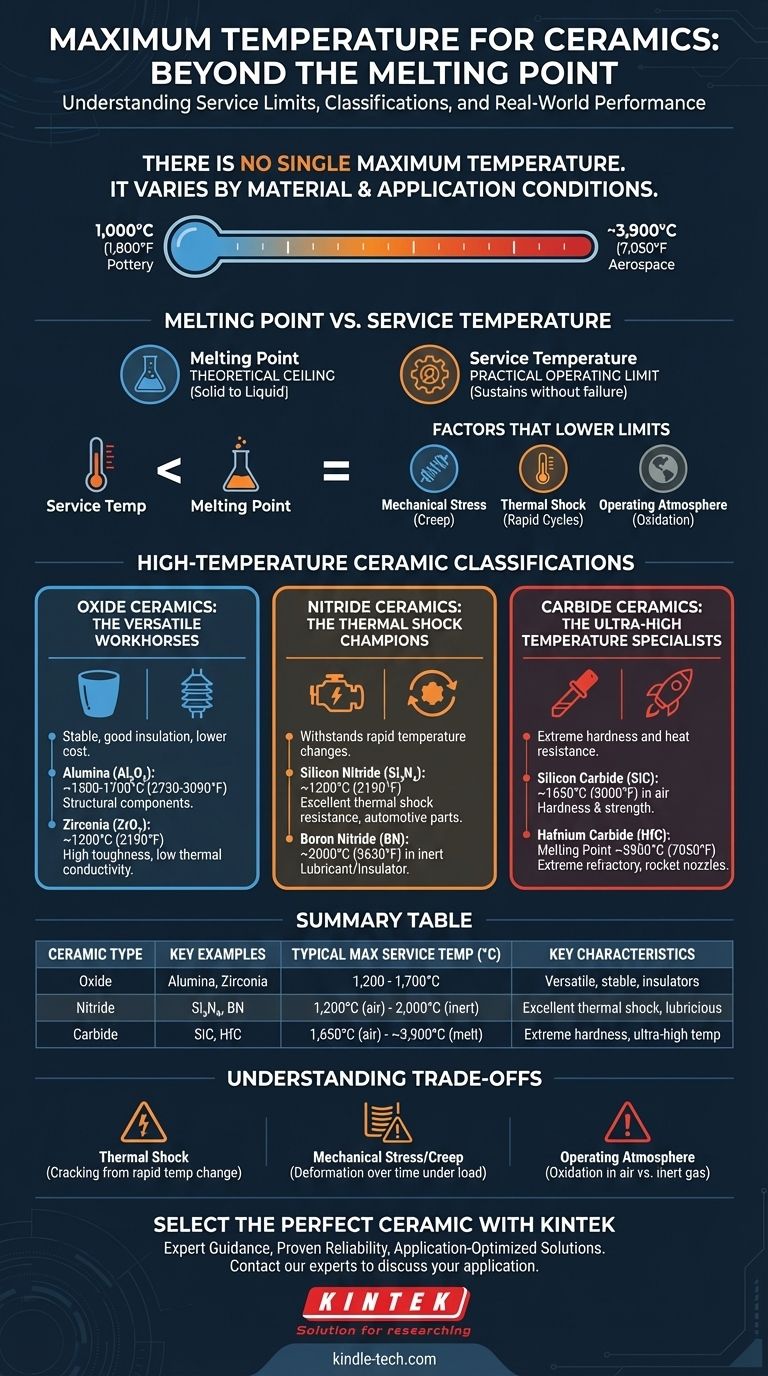

There is no single maximum temperature for ceramics. This is because "ceramic" is a broad category of materials, not a single substance. The maximum temperature a ceramic can withstand ranges from around 1,000°C (1,800°F) for common pottery to nearly 4,000°C (7,200°F) for advanced, exotic materials used in aerospace. The practical limit depends entirely on the specific ceramic composition and the conditions of its use.

A ceramic's melting point is only a theoretical ceiling. The true operational limit, or maximum service temperature, is always lower and is determined by crucial factors like mechanical load, the rate of temperature change (thermal shock), and the chemical environment.

Why "Maximum Temperature" is a Misleading Question

When selecting a material for a high-temperature application, focusing only on the melting point can lead to catastrophic failure. You must instead focus on the maximum service temperature, which accounts for real-world conditions.

Melting Point vs. Service Temperature

The melting point is the temperature at which a material turns from a solid to a liquid. It's a useful benchmark but not a practical operating limit.

The maximum service temperature is the highest temperature a material can sustain in a specific application without degrading or failing. This is the number that truly matters for design and engineering.

Factors That Lower the Service Temperature

Several environmental factors dramatically reduce a ceramic's effective temperature limit. These include mechanical stress, rapid temperature cycles, and the surrounding atmosphere. Ignoring them is the most common reason for failure in high-temperature ceramic applications.

A Practical Classification of High-Temperature Ceramics

To find the right material, you must understand the main families of technical ceramics and their distinct properties. They are generally classified as oxides, nitrides, and carbides.

Oxide Ceramics: The Versatile Workhorses

Oxide ceramics are the most widely used due to their stability, electrical insulation properties, and relatively low cost.

- Alumina (Aluminum Oxide, Al₂O₃): Often the first choice for high-temp structural components. It has a maximum service temperature around 1500-1700°C (2730-3090°F).

- Zirconia (Zirconium Dioxide, ZrO₂): Known for exceptional fracture toughness and low thermal conductivity. Its service temperature is typically below that of high-purity Alumina, around 1200°C (2190°F), but specialized forms can go higher.

Nitride Ceramics: The Thermal Shock Champions

Nitride ceramics are engineered to withstand rapid and extreme temperature changes that would shatter most other materials.

- Silicon Nitride (Si₃N₄): A top performer for applications involving thermal cycling, like automotive engine parts. It maintains high strength up to about 1200°C (2190°F) and has outstanding thermal shock resistance.

- Boron Nitride (BN): Has a structure similar to graphite, making it an excellent high-temperature lubricant and electrical insulator. It is stable in inert atmospheres up to 2000°C (3630°F) but oxidizes in air above 850°C.

Carbide Ceramics: The Ultra-High Temperature Specialists

Carbide ceramics are among the hardest and most heat-resistant materials known to science, often used in cutting tools, armor, and aerospace components.

- Silicon Carbide (SiC): Offers a superb combination of hardness and high-temperature strength, with a service limit approaching 1650°C (3000°F) in air before it begins to oxidize.

- Hafnium Carbide (HfC): One of the most refractory materials known, with a melting point of approximately 3900°C (7050°F). It is reserved for extreme applications like rocket nozzles and nuclear reactor cladding.

Understanding the Trade-offs and Failure Points

Choosing the right ceramic means being aware of its limitations. The highest-melting-point material is rarely the best choice if it fails for other reasons.

Thermal Shock: The Silent Killer

A material with a 2000°C melting point can easily crack at just 300°C if the temperature changes too quickly. Materials with low thermal expansion and high thermal conductivity, like Silicon Nitride, are far superior in resisting thermal shock.

Mechanical Stress and Creep

Applying a physical load to a ceramic at high temperatures can cause it to slowly deform over time, a phenomenon called creep. This deformation can lead to failure far below the theoretical service temperature. Your material choice must account for any load-bearing requirements.

The Operating Atmosphere

The chemical environment is critical. For example, non-oxide ceramics like carbides and nitrides will oxidize (chemically burn) in an oxygen-rich atmosphere at high temperatures, significantly lowering their service limit. In a vacuum or inert gas, they can operate at much higher temperatures.

Making the Right Choice for Your Application

Selecting the correct ceramic is a process of matching the material's complete profile—not just its melting point—to the demands of your specific environment.

- If your primary focus is general-purpose, cost-effective high-temperature use: Start by evaluating Alumina.

- If your primary focus is surviving rapid heating and cooling cycles: Silicon Nitride is the superior choice for its thermal shock resistance.

- If your primary focus is pushing the absolute limits of temperature in an inert environment: Explore ultra-high temperature ceramics like Hafnium Carbide.

- If you need a high-temperature electrical insulator and solid lubricant: Boron Nitride is the leading candidate.

Ultimately, a successful design comes from understanding that the application environment dictates the true limits of the material.

Summary Table:

| Ceramic Type | Key Examples | Typical Max Service Temperature (°C) | Key Characteristics |

|---|---|---|---|

| Oxide Ceramics | Alumina (Al₂O₃), Zirconia (ZrO₂) | 1,200 - 1,700°C | Versatile, stable, good electrical insulators |

| Nitride Ceramics | Silicon Nitride (Si₃N₄), Boron Nitride (BN) | 1,200°C (in air) to 2,000°C (inert) | Excellent thermal shock resistance, lubricious |

| Carbide Ceramics | Silicon Carbide (SiC), Hafnium Carbide (HfC) | 1,650°C (in air) to ~3,900°C (melting point) | Extreme hardness, ultra-high temperature specialists |

Select the Perfect High-Temperature Ceramic with KINTEK

Choosing the right ceramic is critical to the success and safety of your high-temperature process. The wrong material can lead to premature failure, downtime, and costly repairs. KINTEK specializes in providing high-performance lab equipment and consumables, including components made from advanced ceramics precisely matched to demanding thermal, mechanical, and chemical environments.

We help you navigate the complexities of material selection by providing:

- Expert Guidance: Our technical specialists will help you analyze your application's specific requirements—including temperature, thermal cycling, mechanical load, and atmosphere—to recommend the optimal ceramic material.

- Proven Reliability: Source durable, high-quality ceramic components from trusted manufacturers, ensuring your lab equipment operates at peak performance.

- Application-Optimized Solutions: Whether you need the versatility of Alumina crucibles, the thermal shock resistance of Silicon Nitride setters, or the extreme temperature capability of Hafnium Carbide components, we have the solution.

Don't let material limitations constrain your innovation. Contact our experts today to discuss your application and discover how KINTEK's ceramic solutions can enhance the efficiency, safety, and longevity of your laboratory processes.

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- Where are ceramics used in the body? Key Applications in Orthopedics, Dentistry & Bone Repair

- What is the process of making silicon carbide? From Raw Materials to Advanced Ceramics

- What are the 4 main classes of ceramic materials? A Guide to Their Functions and Applications

- Is silicon carbide corrosion-resistant? Unlock Its Power in Extreme Chemical & Thermal Environments

- Are crowns made of ceramic? A Guide to the Best Material for Your Smile

- What role does a carbon template play in nanocasting magnesium oxide? Master Porous Material Precision

- What is the purpose of using ceramic fiber insulation in molten salt pipelines? Ensure Fluidity and Energy Efficiency

- What are the characteristics of sintering in ceramics? Unlock Superior Strength and Durability