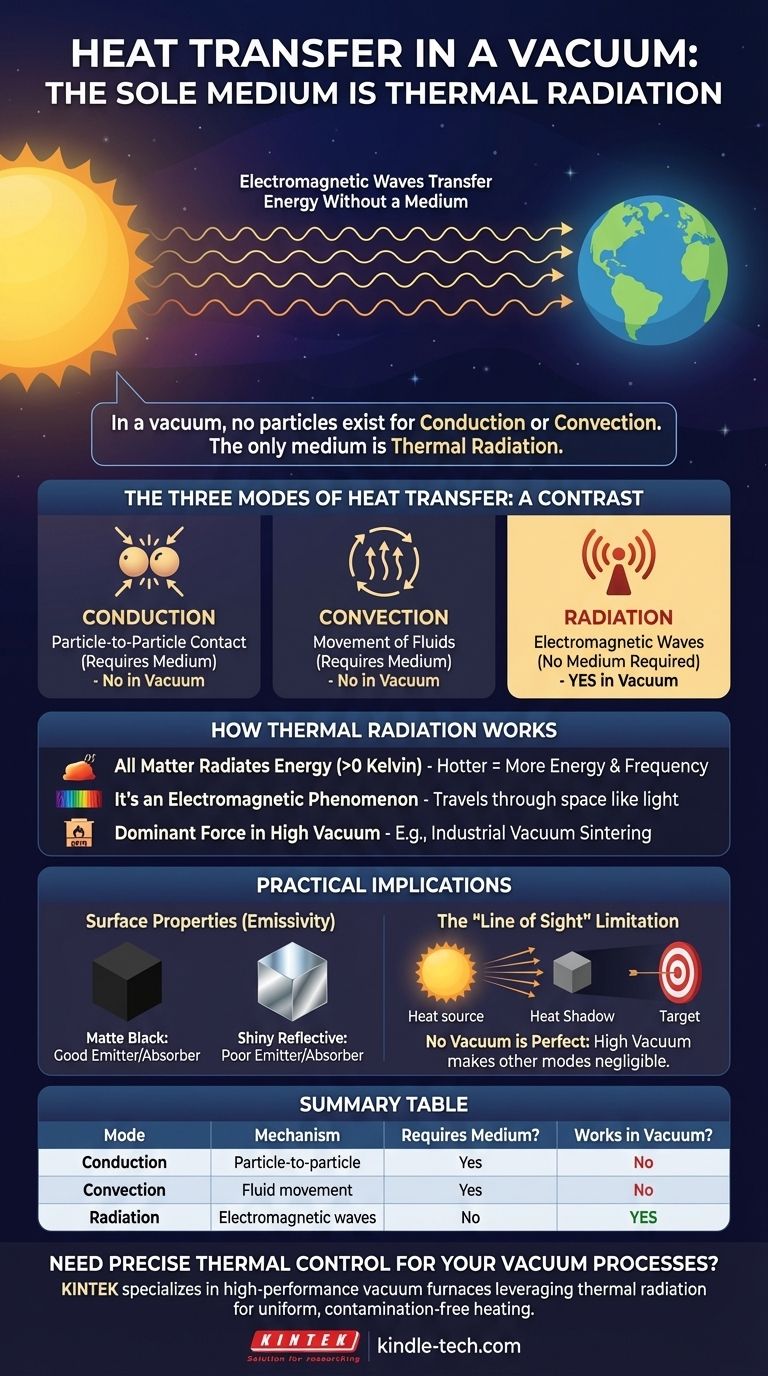

In a vacuum, the sole medium of heat transfer is thermal radiation. This process does not require any physical medium, like solids, liquids, or gases, because it transfers energy in the form of electromagnetic waves. The most intuitive example of this is the sun, which heats the Earth by radiating energy across the vast, empty vacuum of space.

While the familiar concepts of conduction and convection rely on the interaction of particles, a vacuum by definition lacks these particles. Therefore, the only way for heat to travel through this emptiness is through thermal radiation, the same fundamental process that allows light to travel from stars.

The Three Modes of Heat Transfer

To understand why radiation is unique, it's helpful to quickly contrast it with the other two modes of heat transfer.

Conduction: The Particle-to-Particle Transfer

Conduction is the transfer of heat through direct physical contact. Think of a metal spoon left in a hot cup of tea.

The fast-moving, energetic particles of the hot tea collide with the particles of the spoon, transferring their energy. This process requires a medium and cannot occur across a vacuum.

Convection: The Moving Current

Convection involves the transfer of heat through the movement of fluids (liquids or gases). When a portion of a fluid is heated, it becomes less dense and rises, while cooler, denser fluid sinks to take its place.

This creates a circulating current that distributes heat, as seen when boiling water or in a convection oven. It is entirely dependent on the presence of a fluid medium.

How Thermal Radiation Works in a Vacuum

Since a vacuum has no particles for conduction or convection, radiation becomes the only available mechanism.

All Matter Radiates Energy

Any object with a temperature above absolute zero (-273.15°C or 0 Kelvin) constantly emits thermal energy in the form of electromagnetic waves. Hotter objects simply radiate more energy, and at a higher frequency.

It's an Electromagnetic Phenomenon

This "thermal radiation" is part of the same electromagnetic spectrum that includes radio waves, microwaves, and visible light. Most of the heat we feel from a fire or a hot stove top is infrared radiation.

Because these are waves of pure energy, not vibrations of matter, they travel perfectly through the void of space. This is how a satellite in orbit can be heated by the sun on one side and be freezing cold on the other.

The Dominant Force When Other Modes Are Gone

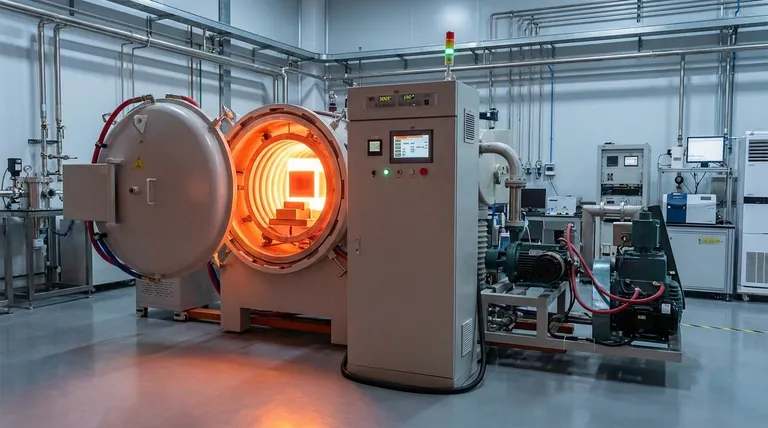

In industrial processes like vacuum sintering, a near-vacuum is created specifically to eliminate conduction and convection. This ensures that heat is transferred almost exclusively by radiation from a heating element to the target material, allowing for very precise and uniform temperature control.

Understanding the Practical Implications

The dominance of radiation in a vacuum has critical real-world consequences.

Surface Properties Are Everything

The rate of radiative heat transfer is heavily dependent on an object's surface characteristics, a property known as emissivity.

A matte, black surface is a near-perfect emitter and absorber of radiation. In contrast, a shiny, reflective surface (like the inside of a vacuum flask or an emergency space blanket) is a poor emitter and absorber, reflecting thermal energy instead.

The "Line of Sight" Limitation

Unlike convection, which can circulate heat around obstacles, thermal radiation travels in straight lines. If an object is not in the direct line of sight of the heat source, it will not receive heat via radiation.

This creates "heat shadows" and is a critical design consideration in everything from spacecraft thermal management to industrial vacuum furnaces.

No Vacuum is Perfect

In practice, achieving a perfect vacuum is impossible. There will always be some residual gas molecules present. However, in a "high vacuum," the number of molecules is so low that heat transfer from conduction and convection becomes negligible, leaving radiation as the overwhelmingly dominant mode.

Applying This to Your Goal

Your approach to thermal radiation will depend entirely on whether you want to encourage or prevent heat transfer.

- If your primary focus is insulation (e.g., in a thermos or cryogenics): Your goal is to minimize radiative heat transfer by using highly reflective surfaces (low emissivity) to bounce the thermal energy back to its source.

- If your primary focus is heating an object (e.g., in space or a vacuum furnace): Your goal is to maximize heat transfer by using surfaces with high emissivity and ensuring a clear line of sight from the heat source.

- If your primary focus is fundamental understanding: The key distinction is that conduction and convection require a material medium, while radiation is pure energy transfer via electromagnetic waves.

Mastering the principles of thermal radiation is essential for controlling energy in any environment where a vacuum is present.

Summary Table:

| Mode of Heat Transfer | Mechanism | Requires a Medium? | Works in a Vacuum? |

|---|---|---|---|

| Conduction | Particle-to-particle contact | Yes | No |

| Convection | Movement of fluids (liquids/gases) | Yes | No |

| Radiation | Electromagnetic waves | No | Yes |

Need precise thermal control for your vacuum processes?

At KINTEK, we specialize in high-performance lab equipment, including vacuum furnaces that leverage thermal radiation for uniform, contamination-free heating. Whether your application is materials research, sintering, or heat treatment, our solutions ensure optimal results.

Contact our experts today to discuss how our equipment can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is vacuum retorting? A Guide to High-Purity Material Processing

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- How does physical vapor deposition work? A Guide to High-Performance Thin Film Coating

- What role do furnaces play in argyrodite electrolytes? Essential Tools for High-Performance Phase Formation

- Can you anneal multiple times? Mastering the Cycle for Perfect Metalwork

- Why must a vacuum drying oven be used at 60°C for NZVI@SiO2-NH2? Protect Your Nanoparticle Integrity

- What are the advantages of multi-stage condensation vacuum equipment? Maximize Efficiency in Lead Anode Slime Processing

- What is vacuum hardening heat treatment? Achieve Superior Metallurgical Results