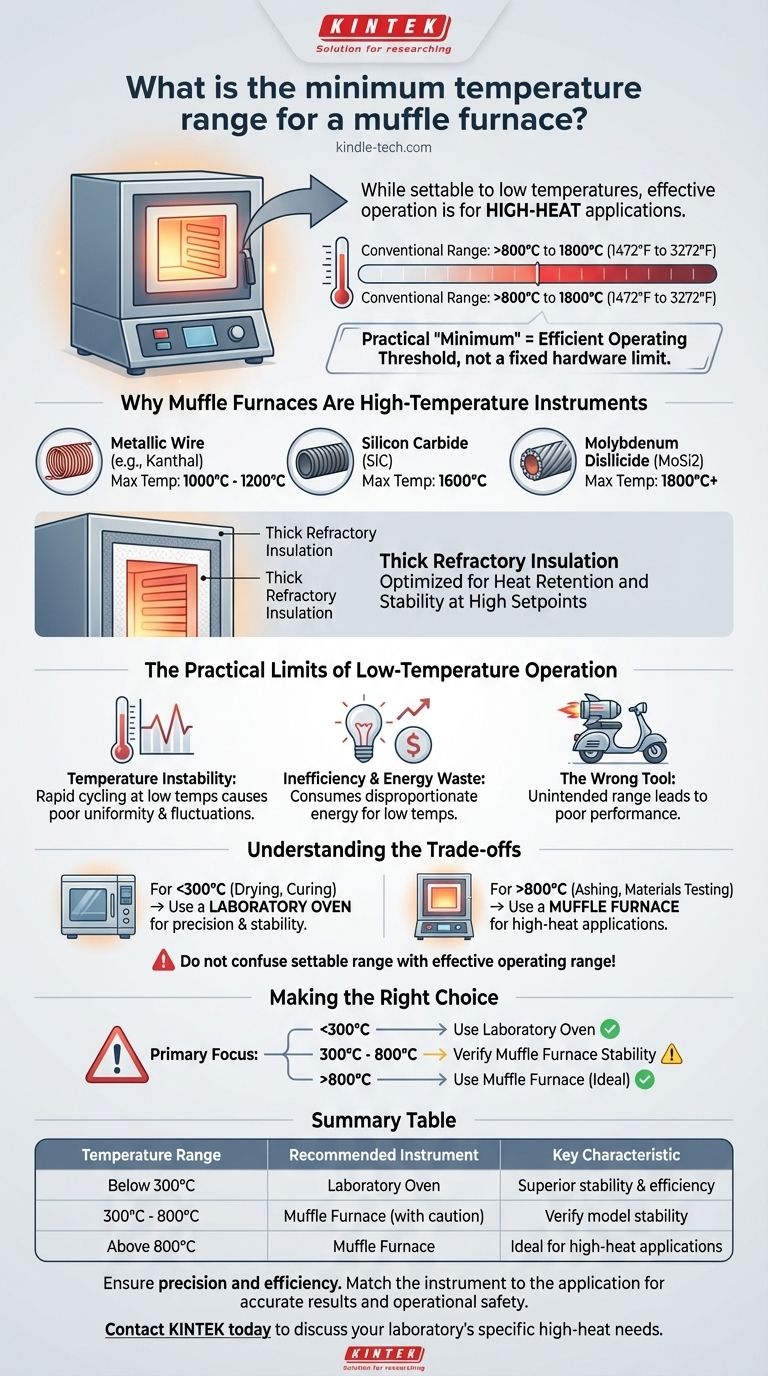

While a muffle furnace can often be set to a low temperature, its effective and practical operating range is designed for high-heat applications. The conventional temperature range for these devices typically starts around 800°C (1472°F) and extends upwards to 1800°C (3272°F), depending on the specific model and its components.

The concept of a "minimum temperature" for a muffle furnace is less about a fixed hardware limit and more about its practical, efficient operating threshold. These furnaces are engineered for high-temperature uniformity and stability, functions they perform poorly at the lower end of the temperature spectrum.

Why Muffle Furnaces Are High-Temperature Instruments

Muffle furnaces are not simply "ovens." Their entire design is optimized for creating and sustaining extreme heat in a controlled environment, which dictates their performance characteristics.

The Critical Role of Heating Elements

The maximum temperature of a furnace is determined by its heating elements.

- Metallic Wire: The most common elements, typically Kanthal (iron-chromium-aluminum alloy), are used for maximum temperatures between 1000°C and 1200°C.

- Silicon Carbide (SiC): For higher temperature needs, these elements allow the furnace to reach up to 1600°C.

- Molybdenum Disilicide (MoSi2): Used in the most advanced units, these elements enable top temperatures of 1800°C or more.

A Design Focused on Heat Retention

A muffle furnace is built with thick, multi-layered refractory insulation. This design is excellent for containing extreme heat and ensuring temperature stability at very high setpoints. This heavy insulation, however, also means the furnace heats and cools slowly.

Understanding the "Temperature Setpoint"

The temperature setpoint is simply the target temperature you program into the controller. While you can technically set this to a low value (e.g., 150°C), the furnace is not designed to maintain such a low temperature with any precision or efficiency.

The Practical Limits of Low-Temperature Operation

The real question isn't what the lowest settable temperature is, but what the lowest effective temperature is. Below its intended range, a muffle furnace becomes the wrong tool for the job.

Why There Isn't a Fixed "Minimum"

Most manufacturers do not specify a minimum operating temperature because the device's primary value is its high-temperature capability. The lower limit is dictated by performance degradation rather than a physical stop.

The Problem of Temperature Instability

At low temperatures, the powerful heating elements must cycle on and off rapidly to avoid overshooting the setpoint. This rapid cycling leads to poor temperature uniformity throughout the chamber and significant fluctuation around your target temperature.

Inefficiency and Energy Waste

Using a muffle furnace for a low-temperature task is highly inefficient. The massive insulation and powerful elements designed for 1000°C will consume a disproportionate amount of energy to maintain a temperature of 200°C, much like using a jet engine to power a scooter.

Understanding the Trade-offs

Choosing the right heating instrument is critical for accurate results and operational efficiency. Using a muffle furnace outside its intended range can lead to significant issues.

Using the Wrong Tool for the Job

For applications below approximately 300°C, such as drying glassware, dehydrating samples, or low-temperature curing, a standard laboratory oven is the correct instrument. These ovens are designed for precision, stability, and efficiency in that lower temperature range.

Misinterpreting the "Operating Range"

Do not confuse the controller's settable range with the furnace's effective operating range. Always refer to the manufacturer's specifications for the intended application, which is invariably high-temperature work like ashing, heat-treating metals, or materials research.

Making the Right Choice for Your Application

Select your heating device based on the temperature required by your process.

- If your primary focus is high-temperature work (>800°C): A muffle furnace is the ideal instrument for processes like ashing, melting metals, and advanced materials testing.

- If your primary focus is mid-range heat treatment (300°C - 800°C): A muffle furnace can function here, but you must verify the specific model's stability in this range.

- If your primary focus is low-temperature work (<300°C): You should use a dedicated laboratory or industrial oven for superior temperature stability and energy efficiency.

Ultimately, matching the instrument to the application ensures precision, repeatability, and operational safety.

Summary Table:

| Temperature Range | Recommended Instrument | Key Characteristic |

|---|---|---|

| Below 300°C | Laboratory Oven | Superior stability & efficiency |

| 300°C - 800°C | Muffle Furnace (with caution) | Verify model stability |

| Above 800°C | Muffle Furnace | Ideal for high-heat applications |

Ensure precision and efficiency in your lab heating processes. Muffle furnaces from KINTEK are engineered for superior performance in high-temperature applications like ashing and materials testing. If your work requires reliable, high-heat equipment, our experts can help you select the perfect model. Contact KINTEK today to discuss your laboratory's specific needs.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a muffle furnace used for burning? Mastering Controlled Thermal Processes

- What is the design and construction of a muffle furnace? A Guide to Its Isolated Heating Chamber

- What role does a high-temperature muffle furnace play in the evaluation of Inconel 625 coatings?

- What role does a laboratory box resistance furnace play in optimizing modified SA508 alloys? Enhance RPV Steel Research

- What is the refractory material in a muffle furnace? Discover the High-Temperature Ceramic System

- What is the necessity of a box-type furnace for UiO66-NH2-TiO2/NiF? Ensure High-Performance Composite Calcination

- How is a high-temperature muffle furnace utilized in RTAC for catalyst preparation? Master Thermal Shock Engineering

- What is sinter used for? Unlocking the Power of Fusing Materials Without Melting