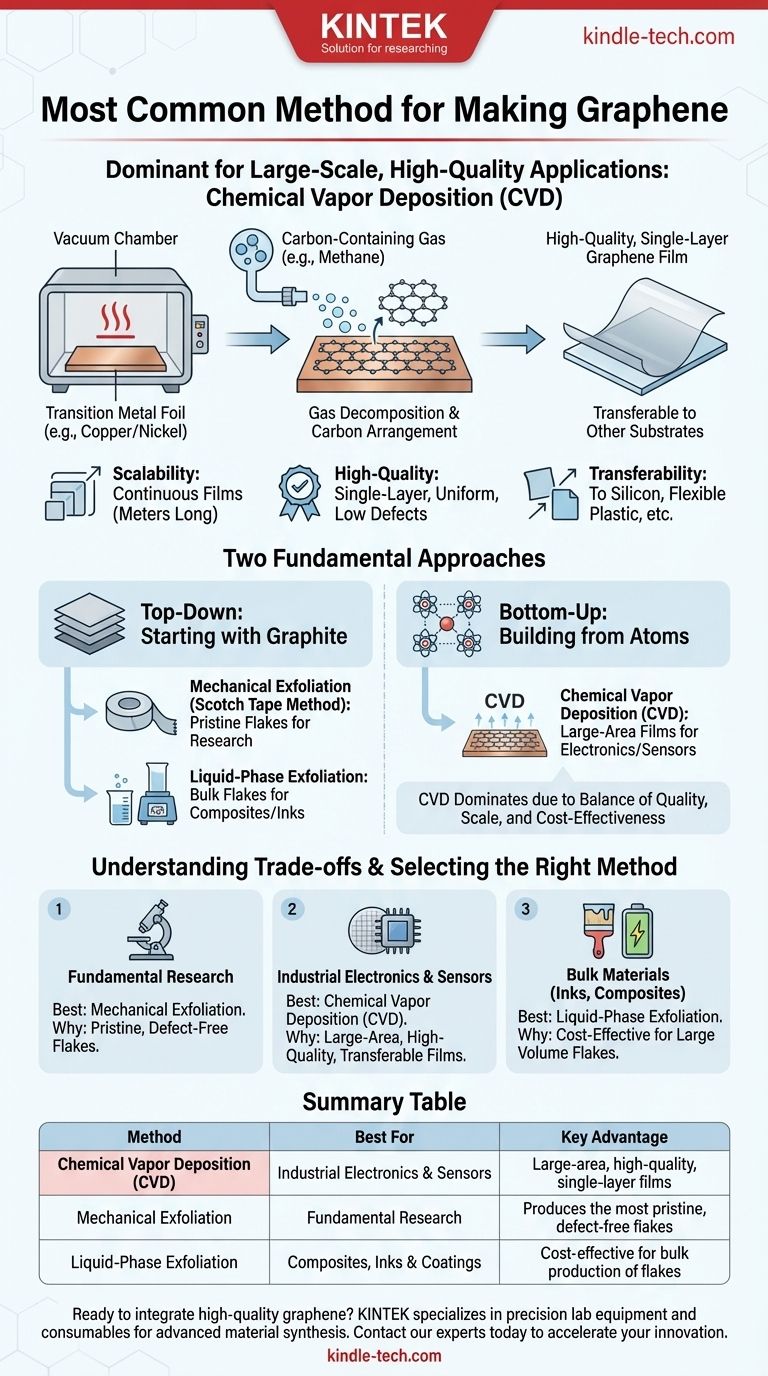

For large-scale, high-quality applications, the most common and commercially viable method for producing graphene is Chemical Vapor Deposition (CVD). While other methods exist for research and bulk production, CVD has become the standard for industries that require large, continuous sheets of graphene for advanced electronics and other technologies.

The "best" method for making graphene is entirely dependent on the end goal. Chemical Vapor Deposition (CVD) is dominant for producing high-quality, large-area films for electronics, while exfoliation methods are better suited for fundamental research or creating bulk graphene for composites and inks.

The Two Fundamental Approaches to Graphene Synthesis

To understand why a specific method is chosen, it's helpful to categorize them into two primary strategies: starting big and going small, or starting small and building up.

Top-Down: Starting with Graphite

The top-down approach begins with bulk graphite—essentially a stack of countless graphene layers—and separates those layers.

This category includes mechanical exfoliation, the original Nobel Prize-winning "Scotch tape" method used to isolate single layers for research.

It also includes liquid-phase exfoliation, where graphite is suspended in a liquid and broken apart using energy (like sonication) to create a dispersion of graphene flakes.

Bottom-Up: Building from Atoms

The bottom-up approach constructs graphene atom by atom on a substrate. This provides greater control over the final structure and quality.

Chemical Vapor Deposition (CVD) is the leading bottom-up method. It involves growing graphene directly onto a substrate from carbon-containing precursor gases.

Why Chemical Vapor Deposition (CVD) Dominates

CVD is considered the most promising technique for industrial adoption because it uniquely balances quality, scale, and cost-effectiveness.

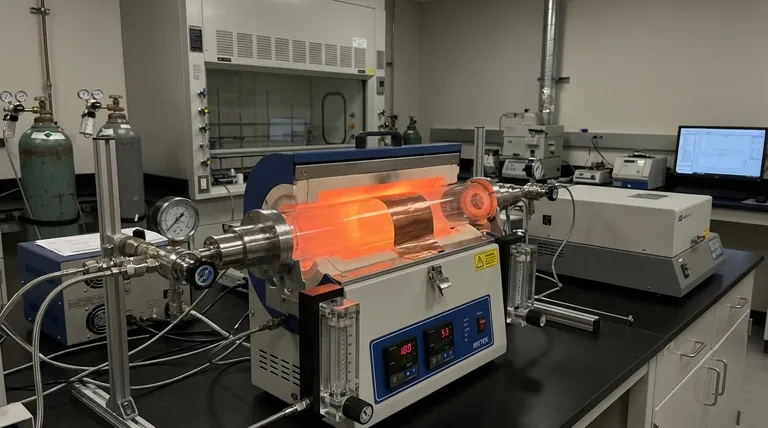

The CVD Process at a Glance

The process involves heating a substrate, typically a transition metal foil like copper or nickel, inside a vacuum chamber.

A carbon-containing gas, such as methane, is then introduced. At high temperatures, the gas decomposes, and carbon atoms arrange themselves into the honeycomb lattice of graphene on the surface of the metal catalyst.

Scalability for Industrial Use

Unlike exfoliation methods that produce small, discrete flakes, CVD can produce continuous graphene films that are meters long. This large-area production is essential for applications like transparent conductive films, electronic wafers, and sensors.

High-Quality, Single-Layer Films

CVD allows for precise control over the growth process, enabling the production of high-quality, uniform, single-layer graphene. This is critical for electronic applications where defects can drastically impair performance.

Transferability to Other Substrates

A key advantage of CVD is that the graphene film can be detached from its growth substrate (e.g., the copper foil) and transferred to virtually any other surface, such as a silicon wafer or flexible plastic. This transferability is vital for integrating graphene into existing manufacturing processes.

Understanding the Trade-offs

No single method is perfect for every application. The dominance of CVD in industry doesn't negate the importance of other techniques in their specific niches.

The Role of Mechanical Exfoliation

While not scalable, mechanical exfoliation is still the gold standard for fundamental research. It produces the most pristine, highest-quality graphene flakes, free from the chemical residues or structural defects that can arise in other methods.

Liquid-Phase Exfoliation for Bulk Composites

For applications that don't require perfect, single-layer sheets, liquid-phase exfoliation is highly effective. It is a cost-effective way to produce large volumes of graphene flakes for use in conductive inks, battery electrodes, polymer composites, and coatings. The electrical quality is lower, but the quantity is high.

The High Cost of Niche Methods

Other methods, such as the thermal decomposition of silicon carbide (SiC), can produce extremely high-quality graphene directly on an insulating substrate. However, the high cost of SiC wafers currently limits this technique to highly specialized, high-performance electronic applications.

Selecting the Right Method for Your Goal

Your choice of graphene synthesis method should be guided entirely by your project's specific requirements for quality, quantity, and cost.

- If your primary focus is fundamental research: Mechanical exfoliation remains the best method for producing small, ultra-high-quality flakes for scientific discovery.

- If your primary focus is industrial-scale electronics or sensors: Chemical Vapor Deposition (CVD) is the established standard for creating large, high-quality, and transferable graphene films.

- If your primary focus is bulk materials like inks, composites, or coatings: Liquid-phase exfoliation offers the most cost-effective path to producing large quantities of graphene flakes.

Ultimately, understanding the trade-offs between these methods empowers you to select the right tool for the job.

Summary Table:

| Method | Best For | Key Advantage |

|---|---|---|

| Chemical Vapor Deposition (CVD) | Industrial Electronics & Sensors | Large-area, high-quality, single-layer films |

| Mechanical Exfoliation | Fundamental Research | Produces the most pristine, defect-free flakes |

| Liquid-Phase Exfoliation | Composites, Inks & Coatings | Cost-effective for bulk production of flakes |

Ready to integrate high-quality graphene into your lab's research or product development? The right equipment is critical for success. KINTEK specializes in precision lab equipment and consumables, including systems tailored for advanced material synthesis. Our expertise can help you select the optimal tools for your specific graphene application, whether you're scaling up for production or pushing the boundaries of research. Contact our experts today to discuss how we can support your laboratory's needs and accelerate your innovation.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques