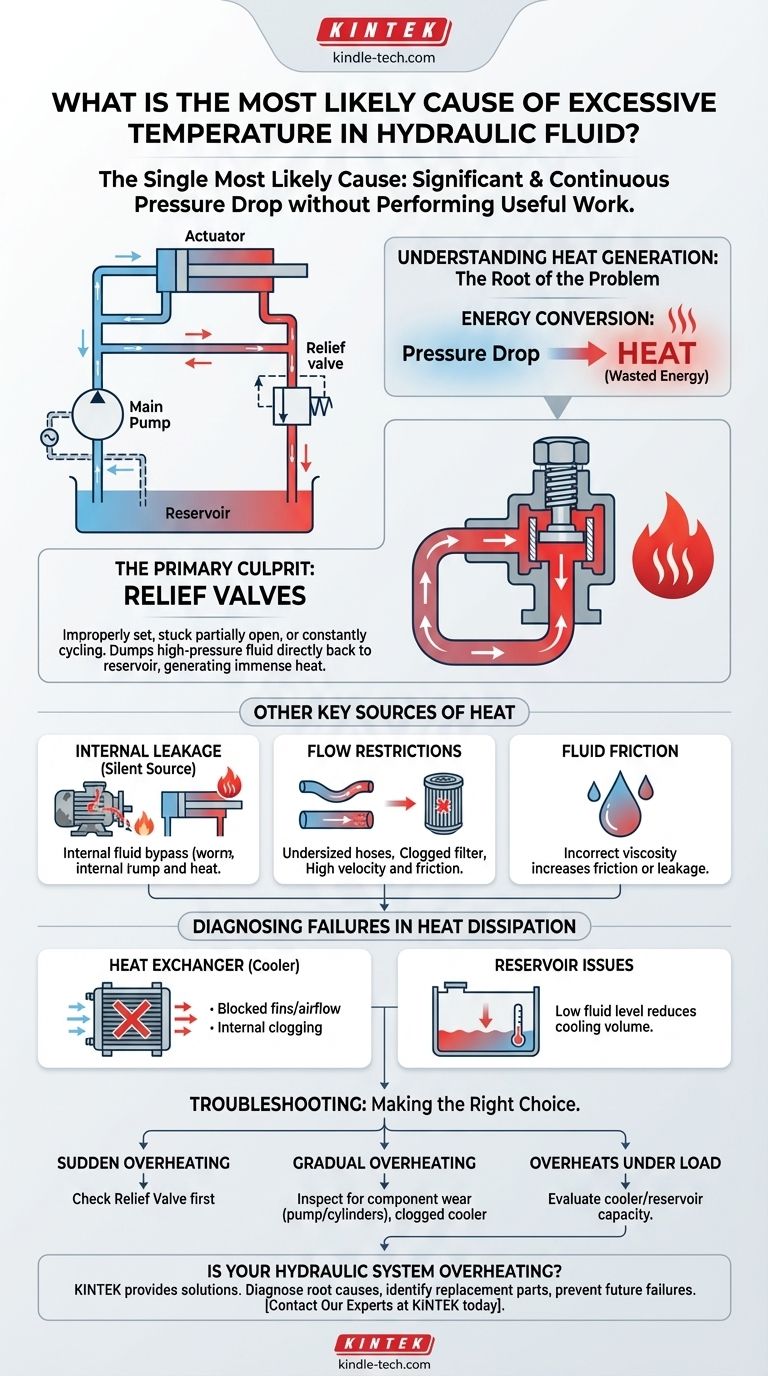

The single most likely cause of excessive temperature in hydraulic fluid is a significant and continuous pressure drop occurring without any useful work being performed. This is most often traced back to a system relief valve that is either improperly set, stuck partially open, or constantly cycling to dump high-pressure fluid directly back to the reservoir.

Overheating is not a root cause, but a symptom of wasted energy. Every unit of heat in your hydraulic system represents hydraulic power that was lost to inefficiency instead of being converted into mechanical force or motion.

Understanding Heat Generation: The Root of the Problem

Heat is the unavoidable byproduct of energy conversion. In a hydraulic system, any restriction to flow or drop in pressure that doesn't result in work generates heat. Identifying the source of this wasted energy is the key to solving an overheating problem.

The Principle of Pressure Drop

The foundational principle is simple: whenever hydraulic fluid moves from a high-pressure area to a low-pressure area without moving an actuator, the energy from that pressure drop is converted directly into heat.

The Primary Culprit: Relief Valves

The main system relief valve is designed to protect the system from over-pressurization. However, if it is set too low, is contaminated and stuck partially open, or if the system design causes it to open frequently, it becomes a massive source of heat.

A continuously operating relief valve acts as a direct, high-volume path for high-pressure oil to return to the tank, generating no work and immense heat. This is the first component to check in any sudden overheating scenario.

Internal Leakage: The Silent Heat Source

As components like pumps, motors, and cylinders wear over time, the internal seals and clearances degrade. This allows high-pressure fluid to leak internally back to a low-pressure side of the component or directly to the reservoir.

This internal leakage is another form of pressure drop without work. While a small amount is normal in many components, excessive leakage from a worn-out pump or cylinder is a very common cause of gradually increasing system temperatures.

Flow Restrictions and Fluid Friction

Other sources of heat come from the energy lost pushing fluid through the system. This includes:

- Undersized hoses or tubing, which create high fluid velocities and friction.

- Clogged filters or strainers, which create a significant pressure drop.

- Incorrect fluid viscosity. Fluid that is too thick increases friction, while fluid that is too thin can increase internal leakage.

Diagnosing Failures in Heat Dissipation

While excess heat generation is the primary problem, a failure in the system's ability to remove heat can expose or worsen the issue. A properly functioning cooling circuit is essential for thermal stability.

The Role of the Heat Exchanger (Cooler)

Most hydraulic systems rely on a heat exchanger (either air-over-oil or water-cooled) to remove heat from the fluid. Its job is to maintain a stable operating temperature, not to compensate for a massive, continuous source of heat generation like a faulty valve.

Common Cooler Failure Points

If the cooling system isn't working, even normal operational heat can become excessive. Check for:

- External blockage: Dirt, dust, or debris clogging the fins of an air cooler, preventing airflow.

- Internal blockage: Sludge or contaminants restricting fluid flow inside the cooler itself.

- No airflow: A failed fan motor or blocked fan shroud.

- No water flow: For water-cooled units, insufficient flow or high water temperature.

Reservoir Issues

The reservoir also plays a role in cooling. A low fluid level reduces the total volume of oil, meaning it cycles through the system more frequently and has less time to cool. It also reduces the surface area of the tank available to dissipate heat into the surrounding air.

Making the Right Choice for Your Goal

Troubleshooting should be a systematic process of elimination, starting with the most likely and easiest-to-check causes.

- If you experienced a sudden, significant temperature increase: Check the main system relief valve and any circuit relief valves first; a stuck or improperly set valve is the most common cause of rapid overheating.

- If the temperature has been gradually increasing over months or years: Focus on sources of wear, such as internal leakage in the main pump or heavily used actuators, and inspect for a slowly clogging cooler or filter.

- If the system only overheats under heavy load or in hot weather: Evaluate the capacity of your cooling system and reservoir; they may be undersized for the peak demand or ambient conditions.

By treating heat as a symptom of wasted energy, you can systematically diagnose and resolve the true root cause of inefficiency in your hydraulic system.

Summary Table:

| Primary Cause | Secondary Cause | Symptom / Action |

|---|---|---|

| Faulty Relief Valve (stuck open, wrong setting) | Clogged or failed heat exchanger | Sudden Overheating: Check relief valve first |

| Internal Leakage (worn pump, cylinders) | Low fluid level / small reservoir | Gradual Overheating: Inspect for component wear |

| Flow Restrictions (undersized lines, clogged filter) | High ambient temperature | Overheats Under Load: Evaluate cooler capacity |

Is your hydraulic system overheating and causing costly downtime?

At KINTEK, we understand that excessive heat is a symptom of inefficiency that can lead to equipment failure and lost productivity. Our expertise in lab and industrial equipment extends to the systems that power them.

Let us help you:

- Diagnose the root cause of your overheating issue, whether it's a faulty component or an undersized cooling system.

- Identify the right replacement parts or system upgrades to restore efficiency and reliability.

- Prevent future failures and protect your valuable equipment investment.

Don't let wasted energy and heat damage your operations. Contact our experts at KINTEK today for a professional assessment and solution tailored to your laboratory or industrial needs.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- High-Purity Titanium Foil and Sheet for Industrial Applications

- High Performance Laboratory Freeze Dryer for Research and Development

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application