In short, a vacuum is non-negotiable for sputter coating. Its primary purpose is to remove air and other unwanted gases from the deposition chamber. This step is critical for two fundamental reasons: it prevents the contamination of the film you are creating and it makes the physical process of sputtering possible in the first place.

Sputtering is a process of atomic-scale transport. Think of the vacuum chamber as a highway. The vacuum's job is to clear all traffic (air molecules) so that sputtered atoms can travel directly from the source target to the destination substrate without collisions or chemical reactions.

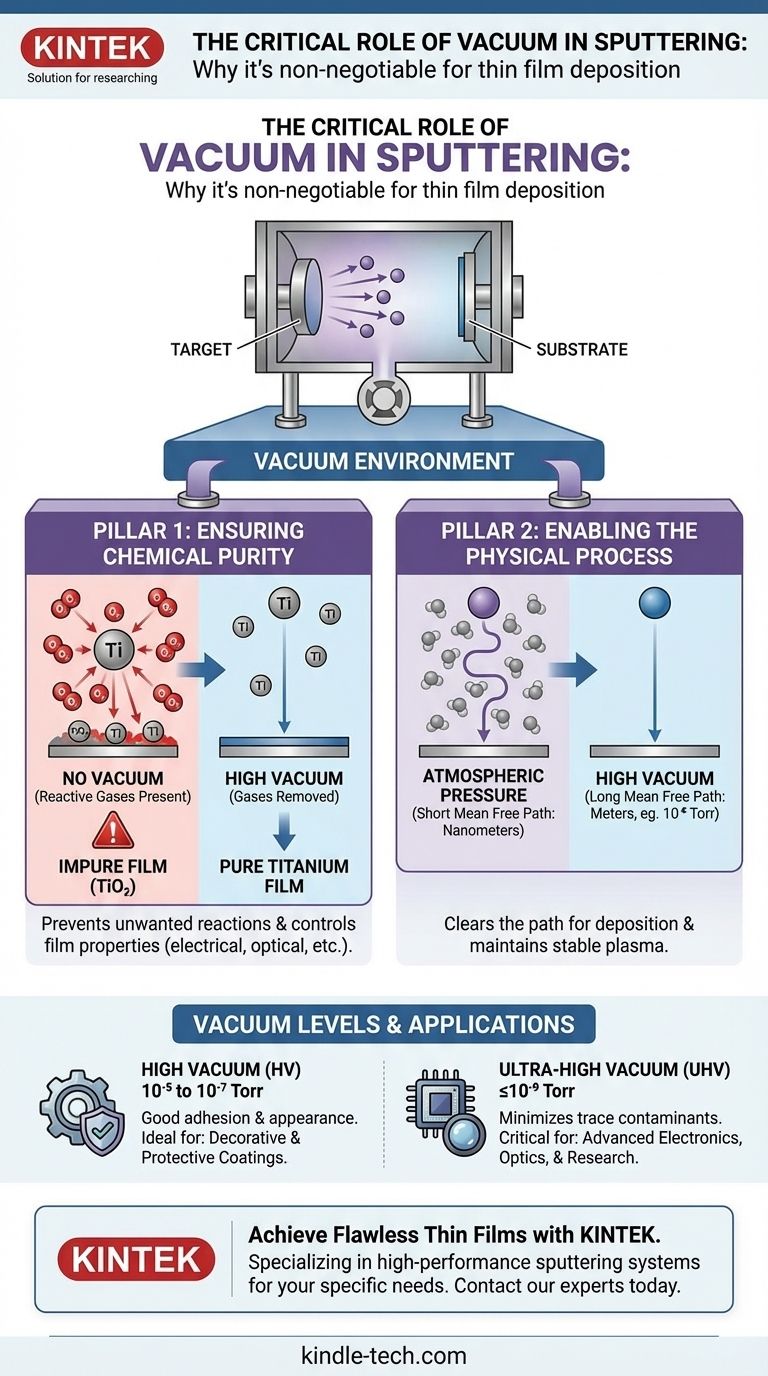

The Dual Role of Vacuum in Sputtering

To understand the necessity of a vacuum, we must look at how it solves two distinct problems: one chemical (purity) and one physical (transport). Failing to address either one will result in a failed deposition.

Pillar 1: Ensuring Chemical Purity

The most intuitive reason for a vacuum is to prevent contamination. The air around us is a mixture of reactive gases, primarily nitrogen (~78%) and oxygen (~21%), along with water vapor and other trace elements.

Preventing Unwanted Reactions

When you deposit a thin film of a material like titanium (Ti), you want the final film to be pure titanium. If oxygen molecules are present in the chamber, they will readily react with the energetic titanium atoms to form titanium oxide (TiO₂), fundamentally changing the film's properties.

Controlling Film Properties

This "contamination" can drastically alter the electrical, optical, and mechanical characteristics of your film. An unwanted oxide or nitride layer can turn a conductive film into an insulator or change the color and refractive index of an optical coating. A high vacuum ensures the film you deposit is the material you intended.

Pillar 2: Enabling the Physical Process

Perhaps more critically, a vacuum is required for the sputtering process to even function efficiently. This is governed by a principle known as the mean free path.

Understanding Mean Free Path

The mean free path is the average distance an atom can travel before it collides with another atom or molecule. At normal atmospheric pressure, this distance is incredibly short—on the scale of nanometers.

Clearing the Path for Deposition

A sputtered atom ejected from the target would collide with billions of air molecules almost instantly. It would lose its energy and never reach the substrate. By pumping the chamber down to a high vacuum (e.g., 10⁻⁶ Torr), we increase the mean free path to tens or even hundreds of meters, far longer than the chamber dimensions.

Maintaining a Stable Plasma

Sputtering relies on creating a plasma, typically from an inert gas like Argon. The presence of other gases like oxygen or nitrogen can interfere with the generation and stability of this plasma, making the sputtering process inefficient and difficult to control. Removing the air ensures a pure, stable Argon plasma can be sustained.

Understanding the Trade-offs and Nuances

Not all vacuums are created equal. The quality of the vacuum directly impacts the quality of the film, and achieving a better vacuum comes at a cost of time and equipment complexity.

High Vacuum (HV) vs. Ultra-High Vacuum (UHV)

For most industrial and decorative coatings, a high vacuum (HV) in the range of 10⁻⁵ to 10⁻⁷ Torr is sufficient. This level is good enough to ensure a long mean free path and reduce reactive gas contamination to an acceptable level for many applications.

For highly sensitive applications, such as semiconductor manufacturing or advanced optical coatings, an ultra-high vacuum (UHV) is required (10⁻⁹ Torr or lower). This minimizes even trace contaminants like water vapor, which can be critical for achieving specific electronic or optical performance.

The Problem of Outgassing

Even in a perfectly sealed chamber, molecules adsorbed on the chamber's internal surfaces (especially water vapor) can be released into the vacuum, acting as a source of contamination. This is why sputtering systems are often pumped for extended periods or "baked out" at high temperatures to drive off these trapped molecules before deposition begins.

Making the Right Choice for Your Goal

The required vacuum level is dictated entirely by the sensitivity of your final application.

- If your primary focus is decorative or protective coatings: A standard high vacuum (HV) is perfectly adequate to ensure good adhesion and the desired appearance.

- If your primary focus is high-performance electronics or optics: A high-quality HV or an entry-level UHV system is critical to prevent performance degradation from chemical impurities.

- If your primary focus is fundamental materials science research: A UHV system is non-negotiable to ensure the properties you are measuring are intrinsic to the material itself, not an artifact of contamination.

Ultimately, controlling the vacuum environment is the foundation upon which all high-quality thin film deposition is built.

Summary Table:

| Role of Vacuum | Key Benefit | Typical Pressure Range |

|---|---|---|

| Chemical Purity | Prevents reactions with air (O₂, N₂, H₂O) | 10⁻⁵ to 10⁻⁷ Torr (HV) |

| Physical Process | Enables atom transport via long mean free path | 10⁻⁹ Torr or lower (UHV) |

| Plasma Stability | Maintains a pure, stable argon plasma | Varies by application |

Achieve Flawless Thin Films with KINTEK

Your research and production quality depend on a controlled vacuum environment. KINTEK specializes in high-performance sputtering systems and vacuum solutions tailored for laboratories and industrial coating applications. Whether you need reliable high-vacuum for protective coatings or ultra-high-vacuum for sensitive electronics, our expertise ensures your films are pure, consistent, and high-performing.

Let us help you build the foundation for superior results. Contact our experts today to discuss your specific needs and how our lab equipment can advance your projects.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition