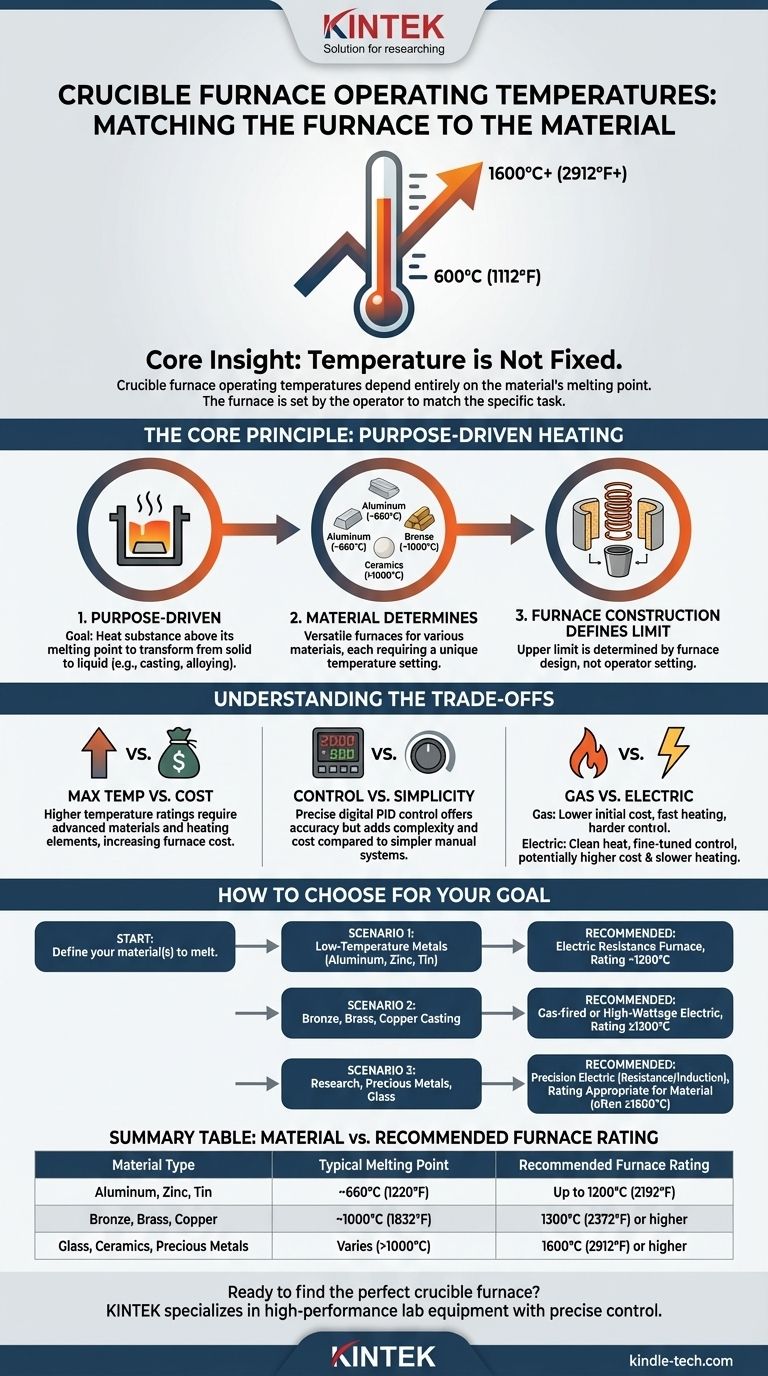

Crucible furnace operating temperatures are not fixed; they are variable and dictated entirely by the melting point of the material being processed. While some simple furnaces for low-temperature metals might operate around 600-1100°C (1112-2012°F), high-performance models for foundry work or ceramics can easily exceed 1600°C (2912°F). The furnace's temperature is set by the operator to match a specific task.

The core insight is that a crucible furnace doesn't have one "operating temperature." Instead, it has a maximum temperature rating. The crucial question is not what the furnace's temperature is, but whether its maximum rating is high enough for the specific material you need to melt.

The Core Principle: Match the Furnace to the Material

A crucible furnace is a tool designed for a specific purpose: to liquefy a solid material. The temperature required to do this is a property of the material itself, not the furnace.

Temperature is Purpose-Driven

The primary goal of a crucible furnace is to heat a substance above its melting point. This transforms it from a solid to a liquid state for casting, alloying, or refining.

This is fundamentally different from other heating processes. For example, a sintering furnace intentionally operates below the melting point to fuse particles together without liquefying the bulk material.

Material Determines the Target Temperature

The versatility of crucible furnaces means they are used for a vast range of materials, each with its own unique melting point.

A furnace melting aluminum will be set to just over 660°C (1220°F). The same foundry melting bronze would need to set its furnace to over 1000°C (1832°F). Specialized furnaces for glass or certain ceramics operate at even higher temperatures.

Furnace Construction Defines the Limit

While the operator sets the target temperature, the furnace's construction defines the maximum achievable temperature. This upper limit is determined by its heating elements, insulation, and, most critically, the crucible material.

Understanding the Trade-offs

Selecting a furnace involves balancing its capabilities against your specific needs and budget. There is no single "best" furnace, only the most appropriate one for the job.

Maximum Temperature vs. Cost

A direct correlation exists between a furnace's maximum temperature rating and its cost. Reaching higher temperatures requires more advanced heating elements, thicker insulation, and crucibles made from more exotic materials like pure silicon carbide or other ceramics, all of which increase the price.

Control vs. Simplicity

The references note the advantage of "precise temperature control." This is typically achieved with digital PID (Proportional-Integral-Derivative) controllers and thermocouples. While these systems offer superior accuracy, they add complexity and cost compared to simpler, manually adjusted gas furnaces or basic electric models.

Gas vs. Electric Power

Gas-fired furnaces often offer a lower initial cost and the ability to reach high temperatures very quickly. However, they can be harder to control with precision.

Electric resistance or induction furnaces provide exceptionally clean heat and fine-tuned temperature control, but may have a higher purchase price and slower heating cycles.

How to Choose for Your Goal

The right choice depends entirely on what you plan to melt. Define your materials first, then find a furnace that can safely and efficiently meet that temperature requirement.

- If your primary focus is low-temperature metals (e.g., aluminum, zinc, or tin): A simple and cost-effective electric resistance furnace with a maximum rating around 1200°C (2192°F) is more than sufficient.

- If your primary focus is bronze, brass, or copper casting: You need a more robust furnace, either gas-fired or a higher-wattage electric model, rated for at least 1300°C (2372°F) to provide a safe operating margin.

- If your primary focus is research, precious metals, or glass: A precision-controlled electric furnace (resistance or induction) with a high-purity crucible and a temperature rating appropriate for your specific material is essential.

Ultimately, selecting the right furnace begins with a clear understanding of the specific materials you intend to melt.

Summary Table:

| Material Type | Typical Melting Point | Recommended Furnace Rating |

|---|---|---|

| Aluminum, Zinc, Tin | ~660°C (1220°F) | Up to 1200°C (2192°F) |

| Bronze, Brass, Copper | ~1000°C (1832°F) | 1300°C (2372°F) or higher |

| Glass, Ceramics, Precious Metals | Varies (>1000°C) | 1600°C (2912°F) or higher |

Ready to find the perfect crucible furnace for your lab's needs? KINTEK specializes in high-performance lab equipment, offering a range of crucible furnaces with precise temperature control for materials from aluminum to advanced ceramics. Our experts will help you select a furnace that matches your material's melting point and your operational requirements. Contact our team today for a personalized consultation and enhance your melting processes with KINTEK reliability.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vertical Laboratory Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance