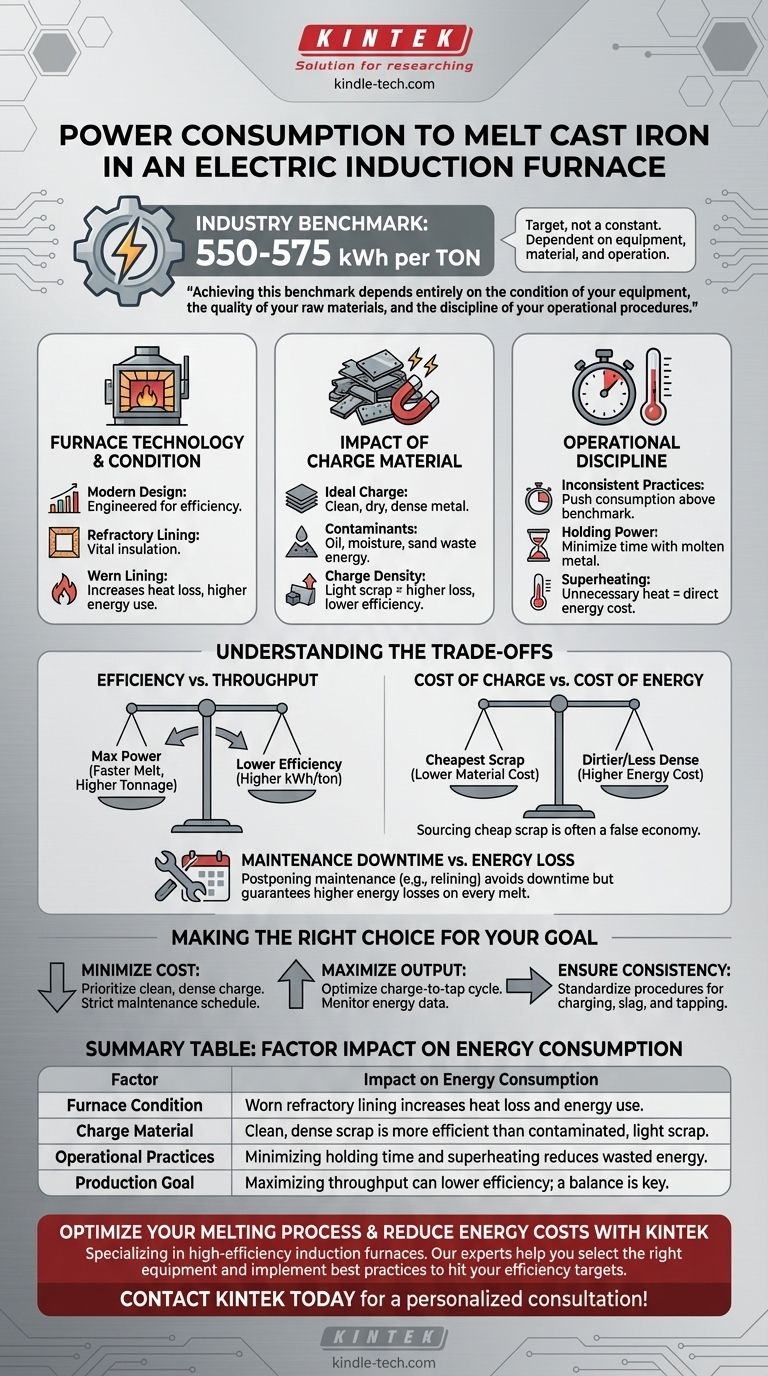

To melt one ton of cast iron in an electric induction furnace, the industry benchmark for power consumption is between 550 and 575 kWh. This figure represents the electrical energy required to take solid iron at room temperature, heat it past its melting point, and prepare it for pouring.

The specific energy consumption of 550-575 kWh/ton is not a fixed constant but an efficiency target. Achieving this benchmark depends entirely on the condition of your equipment, the quality of your raw materials, and the discipline of your operational procedures.

Deconstructing the Energy Requirement: Factors Beyond the Benchmark

The benchmark figure provides a vital starting point, but in practice, your actual energy consumption can vary significantly. Understanding the variables that influence this number is the key to managing costs and optimizing your melting process.

The Role of Furnace Technology and Condition

Modern, well-maintained induction furnaces are engineered to operate within this efficiency range. The furnace's condition is paramount.

The refractory lining of the furnace acts as insulation. As this lining wears down and becomes thinner, heat loss through the furnace walls increases dramatically, requiring more energy to maintain the target temperature.

The Critical Impact of Charge Material

The material you put into the furnace has a direct and significant effect on energy consumption. The ideal charge consists of clean, dry, and dense pieces of metal.

Contaminants like oil, moisture, sand, or excessive rust must be burned off or melted, consuming energy without contributing to the final molten iron yield.

Charge density is also crucial. Light, loose scrap (like machining turnings) has a large surface area, leading to higher metal loss from oxidation and less efficient energy transfer compared to heavy, dense scrap.

The Human Factor: Operational Discipline

How the furnace is operated from shift to shift is a major driver of energy efficiency. Inconsistent practices can easily push consumption well above the benchmark.

Holding power is the energy required simply to keep the metal molten without increasing its temperature. Minimizing the time the furnace holds liquid metal before tapping is a critical energy-saving practice.

Superheating, or raising the metal's temperature far above what is necessary for casting, is a common source of wasted energy. Every degree of unnecessary heat represents a direct energy cost.

Understanding the Trade-offs in Melting Operations

Optimizing for the lowest possible energy consumption often involves balancing competing operational goals. The ideal process is rarely the one that minimizes a single variable.

Efficiency vs. Throughput

Running a furnace at its maximum power rating can accelerate the melting process and increase production tonnage. However, this often comes at the cost of lower electrical efficiency, pushing the kWh/ton figure higher.

Conversely, a slower, more controlled melt cycle might be more energy-efficient but could fail to meet production demands.

Cost of Charge vs. Cost of Energy

Sourcing the cheapest available scrap metal is often a false economy. Low-cost scrap is frequently dirtier or less dense, which directly increases the energy required to melt it.

A smart operation constantly balances the price of raw materials against the utility cost needed to process them into a usable product.

Maintenance Downtime vs. Energy Loss

Postponing essential furnace maintenance, such as relining the refractory, avoids immediate downtime and labor costs.

However, continuing to run with a worn lining guarantees higher energy losses on every single melt. This deferred cost almost always outweighs the initial savings from delaying the maintenance.

Making the Right Choice for Your Goal

Controlling energy consumption requires a clear understanding of your primary operational objective. Your strategy should align with your specific goals.

- If your primary focus is minimizing operational cost: Prioritize sourcing clean, dense charge material and adhere to a strict preventative maintenance schedule for the furnace lining.

- If your primary focus is maximizing production output: Focus on optimizing the entire charge-to-tap cycle time, while monitoring energy data to prevent excessive waste from inefficient practices.

- If your primary focus is ensuring process consistency: Implement and enforce standardized operating procedures for charging methods, slag management, and final tapping temperatures.

Ultimately, treating electrical energy as a key raw material—one that can be measured, managed, and controlled—is the foundation of an efficient and profitable melting operation.

Summary Table:

| Factor | Impact on Energy Consumption |

|---|---|

| Furnace Condition | Worn refractory lining increases heat loss and energy use. |

| Charge Material | Clean, dense scrap is more efficient than contaminated, light scrap. |

| Operational Practices | Minimizing holding time and superheating reduces wasted energy. |

| Production Goal | Maximizing throughput can lower efficiency; a balance is key. |

Ready to optimize your melting process and reduce energy costs? KINTEK specializes in high-efficiency lab and foundry equipment, including induction furnaces designed for superior performance and cost control. Our experts can help you select the right furnace and implement best practices to hit your efficiency targets. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications