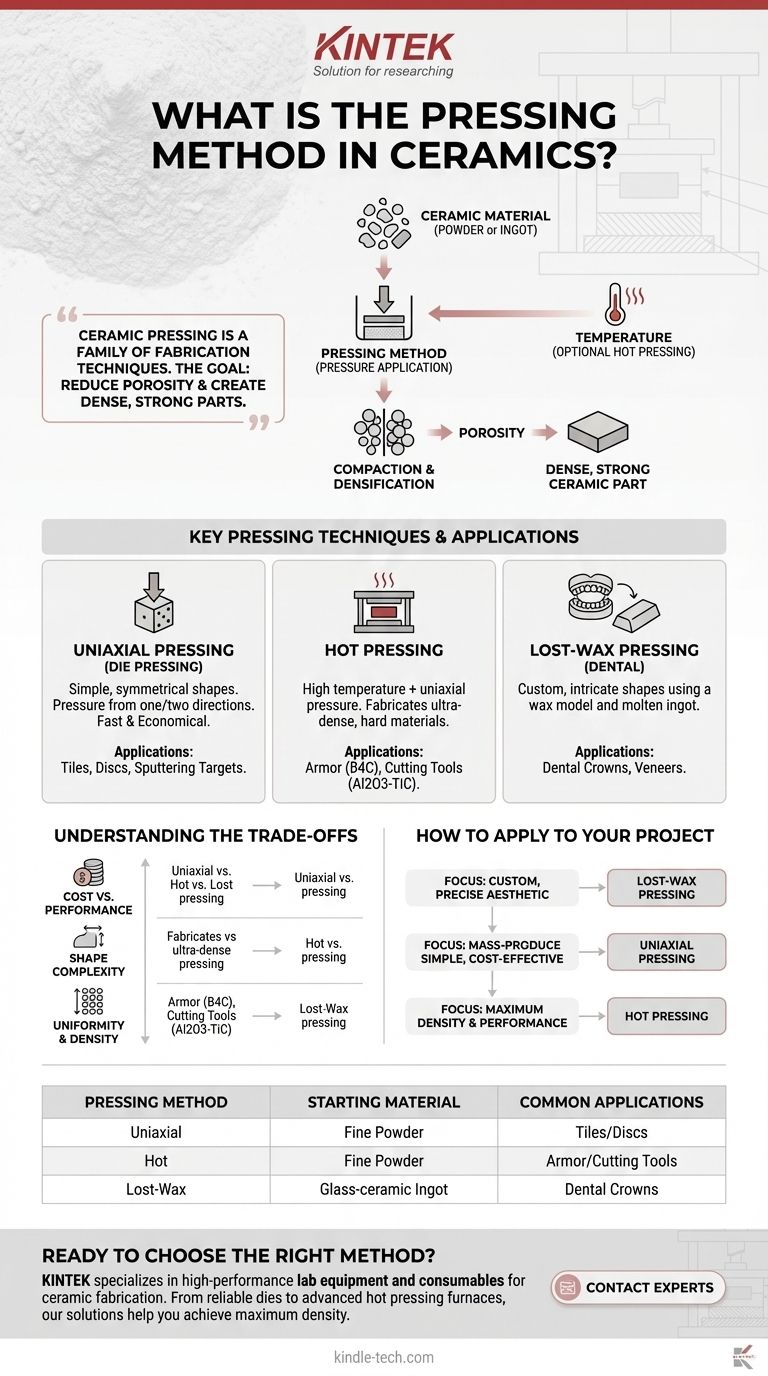

At its core, the pressing method in ceramics is a process used to shape and consolidate ceramic materials by applying high pressure. This can involve compacting a fine powder into a desired form within a mold (a die) or, in other cases, forcing a molten ceramic ingot into a pre-made cavity, such as in the lost-wax technique common in dentistry.

Ceramic pressing is not a single process, but a family of fabrication techniques. The fundamental goal is always the same: to reduce porosity and create a dense, strong ceramic part by forcing particles into intimate contact, often with the aid of heat.

The Fundamental Principle: Compaction and Densification

Ceramic pressing is a foundational process in modern materials science, used to transform loose or molten material into a solid, functional object.

The Starting Material

The process begins with the ceramic material, which can be in the form of a fine, dry powder or a pre-formed glass-ceramic ingot. The choice of starting material depends entirely on the specific pressing technique being used.

The Role of Pressure

Pressure is the primary force in this method. It compacts the powder or drives the molten material, eliminating the empty spaces (porosity) between particles. This densification is critical for achieving the strength, hardness, and other performance characteristics expected of a finished ceramic component.

The Importance of Temperature

In many advanced applications, pressure is combined with high temperature. Heat softens the ceramic particles, allowing them to deform and bond more easily under pressure. This process, known as hot pressing, enables the fabrication of ultra-dense, high-performance materials that would be impossible to create with pressure alone.

Key Pressing Techniques and Their Purpose

The term "pressing" covers several distinct methods, each designed for specific applications and outcomes.

Uniaxial Pressing (Die Pressing)

This is the most common and straightforward method. Ceramic powder is placed in a rigid die, and pressure is applied from one or two directions (uniaxially) by a plunger. It is fast, economical, and ideal for producing simple, symmetrical shapes like tiles, discs, and sputtering targets.

Hot Pressing

As mentioned in advanced applications, hot pressing involves applying uniaxial pressure to the ceramic powder at a high temperature, simultaneously heating and pressing it. This is essential for fabricating extremely hard, non-oxide ceramics like silicon nitride, boron carbide (B4C) for armor, and advanced cutting tools from materials like Al2O3-TiC.

Lost-Wax Pressing (for Dental Ceramics)

This highly specialized technique is used to create custom-fitted restorations like crowns and veneers. A wax model of the final part is made, encased in an investment material, and then burned out in a furnace, leaving a precise mold. A ceramic ingot and plunger are inserted, and the furnace presses the now-molten ceramic into the mold cavity.

Understanding the Trade-offs

No single pressing method is universally superior. The choice involves a calculated balance of cost, complexity, and desired material properties.

Cost vs. Performance

Uniaxial pressing is the most cost-effective method for high-volume production of simple parts. Hot pressing, conversely, requires expensive equipment and significant energy but is necessary for achieving the peak performance and density required in technical ceramics like wear parts or cutting tools.

Shape Complexity

Die pressing is limited to relatively simple geometries due to the rigid die and unidirectional pressure. The lost-wax technique, while complex, allows for the creation of intricate, custom-fit shapes required in dentistry.

Uniformity and Density

Uniaxial pressing can sometimes result in slight density variations within the part. Methods that apply pressure more uniformly, such as isostatic pressing (a related technique), are used when consistent density throughout a complex shape is critical.

How to Apply This to Your Project

Your choice of pressing method must be dictated by the end goal for your ceramic component.

- If your primary focus is creating custom, high-precision aesthetic parts (like dental restorations): The lost-wax pressing method is the industry standard for its unmatched ability to replicate detailed shapes.

- If your primary focus is mass-producing simple, cost-effective shapes (like basic insulators or substrates): Uniaxial (die) pressing offers the most economical and high-volume solution.

- If your primary focus is achieving maximum density and performance in advanced materials (like armor or cutting tools): Hot pressing is essential for consolidating difficult-to-sinter technical ceramics and achieving superior mechanical properties.

Understanding these distinct pathways empowers you to select the precise fabrication process required to achieve your desired ceramic properties.

Summary Table:

| Pressing Method | Starting Material | Key Feature | Common Applications |

|---|---|---|---|

| Uniaxial Pressing | Fine Powder | Cost-effective, high-volume | Tiles, discs, sputtering targets |

| Hot Pressing | Fine Powder | High temperature + pressure | Armor (B4C), cutting tools (Al2O3-TiC) |

| Lost-Wax Pressing | Glass-ceramic Ingot | Custom, intricate shapes | Dental crowns, veneers |

Ready to choose the right ceramic pressing method for your project? KINTEK specializes in providing high-performance lab equipment and consumables for materials science and ceramic fabrication. Whether you need reliable dies for uniaxial pressing or advanced furnaces for hot pressing, our solutions are designed to help you achieve maximum density and superior material performance. Contact our experts today to discuss how we can support your laboratory's specific ceramic processing needs!

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What role does an industrial-grade omnidirectional press play in the preparation of ultra-fine grained VT6 titanium?

- What is the cold isostatic pressing method? Achieve Uniform Density in Complex Parts

- For which types of components and materials is semi-isostatic pressing particularly suitable? Optimize Your Production

- What is isostatic pressing method for ceramics? Achieve Uniform Density for Complex Parts

- What is the purpose of using a sealed laminated bag in CIP for battery components? Ensure Purity and High Density.

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What are the advantages of isostatic pressing? Achieve Superior Material Integrity and Design Freedom

- Why is a cold isostatic press preferred over a uniaxial press for tungsten powder? Achieve Uniform Powder Compaction