Despite their immense power and versatility, hydraulic press machines are not without significant operational challenges. The core problems stem from their reliance on hydraulic fluid, leading to high maintenance demands from potential leaks, slower operational speeds compared to mechanical alternatives, and notable energy consumption.

The fundamental challenge of a hydraulic press isn't a single flaw, but a series of operational trade-offs. Its incredible force generation is balanced by higher maintenance demands, slower cycle times, and potential safety and environmental concerns related to its hydraulic fluid.

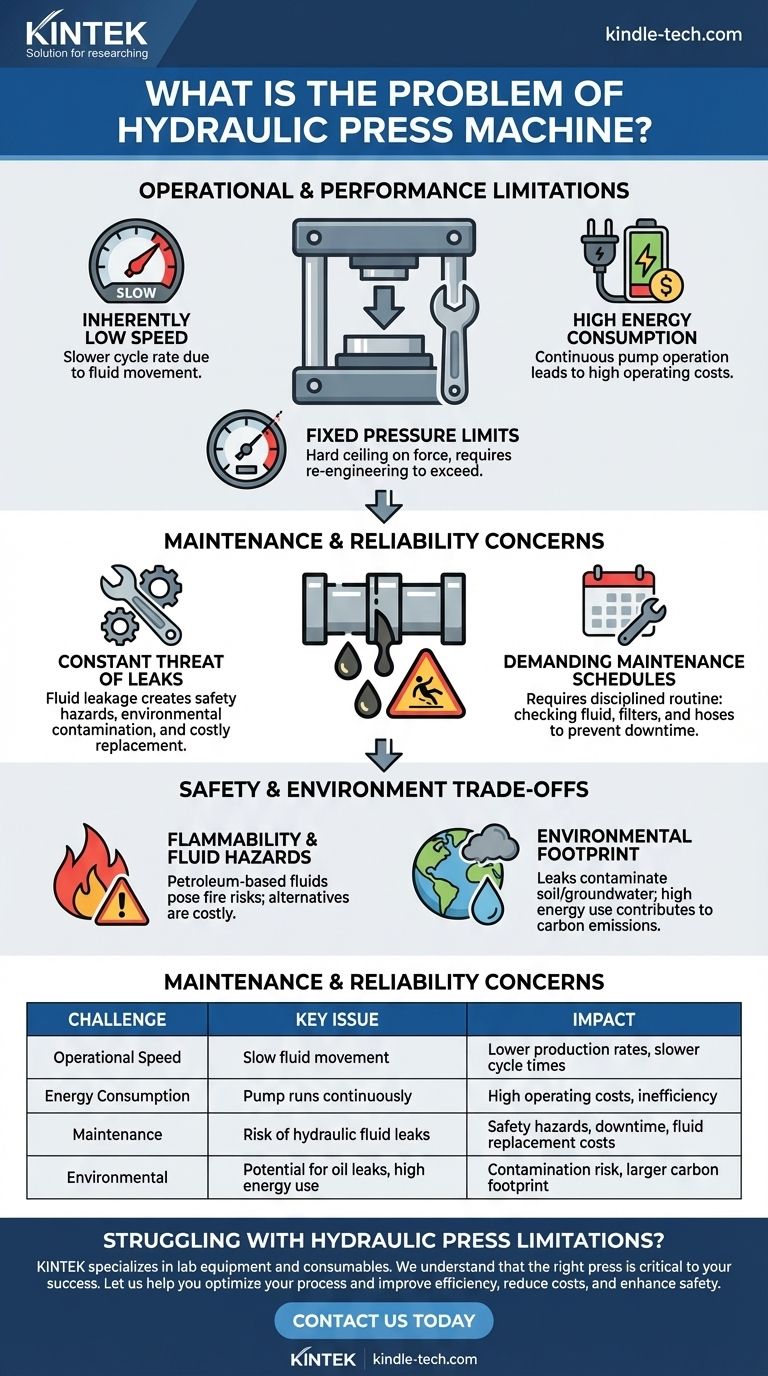

Operational and Performance Limitations

A hydraulic press generates force by moving fluid, a process that introduces inherent constraints on its performance and efficiency.

Inherently Low Speed

The operational speed, or cycle rate, of a hydraulic press is often low. This is because a significant volume of hydraulic fluid must be moved by a pump to build the required pressure, which is a fundamentally slower process than the direct crank motion of a mechanical press.

High Energy Consumption

Hydraulic systems can be inefficient. The pump motor often runs continuously to maintain system pressure, consuming considerable energy even when the press is idle between cycles. This leads to higher long-term operating costs.

Fixed Pressure Limits

Every hydraulic system is designed with a maximum pressure limit, regulated by a relief valve. While this is a critical safety feature, it also represents a hard ceiling on the force the machine can deliver, which cannot be exceeded without re-engineering the system.

Maintenance and Reliability Concerns

The defining component of a hydraulic press—its fluid—is also the source of its most common maintenance and reliability issues.

The Constant Threat of Leaks

Fluid leakage is the most persistent problem. Even minor leaks from seals, hoses, or fittings can lead to significant issues, including safety hazards (slip-and-fall), environmental contamination, costly fluid replacement, and a loss of system pressure and performance.

Demanding Maintenance Schedules

These machines are not "set it and forget it." They require a disciplined maintenance routine that includes regularly checking fluid levels, inspecting for leaks, changing filters, and monitoring the condition of hoses and seals to prevent unexpected downtime.

Understanding the Trade-offs: Safety and Environment

While powerful, a hydraulic press introduces specific risks and environmental considerations that must be managed.

Flammability and Fluid Hazards

Many standard hydraulic oils are petroleum-based and flammable, creating a fire risk in certain environments. While fire-resistant fluids are available, they are typically more expensive and may have different performance characteristics.

The Environmental Footprint

The combination of high energy consumption and the potential for oil leaks gives hydraulic presses a notable environmental footprint. A leak can contaminate groundwater and soil, requiring costly cleanup, while the machine's energy use contributes to its overall carbon emissions.

Making the Right Choice for Your Application

Ultimately, the "problems" of a hydraulic press are only problems if the machine is mismatched to the task.

- If your primary focus is immense, controllable force: The hydraulic press is often the superior choice for applications like deep drawing or forging where full tonnage is needed throughout the entire stroke.

- If your primary focus is high-speed production: A mechanical press is typically a more efficient solution for high-volume, repetitive tasks like blanking or stamping that require rapid cycle times.

- If your primary focus is cleanliness and low maintenance: An all-electric press may be the best alternative, as it completely eliminates the potential for fluid leaks and often provides greater energy efficiency.

Understanding these inherent challenges is the first step toward correctly matching the machine's capabilities to your specific operational needs.

Summary Table:

| Challenge | Key Issue | Impact |

|---|---|---|

| Operational Speed | Slow fluid movement | Lower production rates, slower cycle times |

| Energy Consumption | Pump runs continuously | High operating costs, inefficiency |

| Maintenance | Risk of hydraulic fluid leaks | Safety hazards, downtime, fluid replacement costs |

| Environmental | Potential for oil leaks, high energy use | Contamination risk, larger carbon footprint |

Struggling with Hydraulic Press Limitations?

While hydraulic presses are powerful, their operational challenges—like slow speeds, high energy bills, and persistent maintenance—can hinder your productivity and profitability.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. We understand that the right press is critical to your success. Whether you need a high-speed mechanical press for rapid production or a clean, efficient electric press to eliminate fluid leaks, our experts can help you find the perfect solution for your specific application.

Let us help you optimize your process. Contact us today for a consultation and discover how the right equipment can boost your efficiency, reduce costs, and improve safety.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy