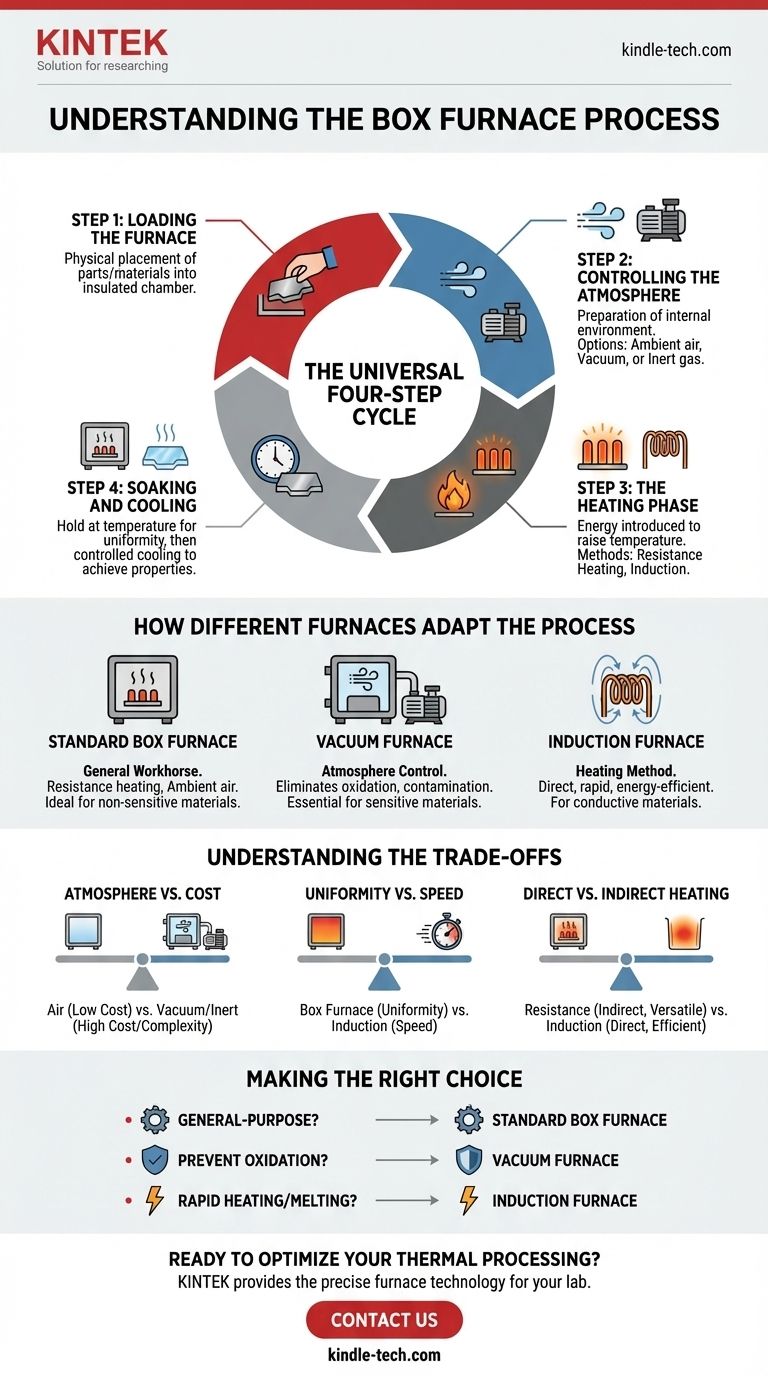

At its core, a box furnace operates on a fundamental four-step process. The material is loaded into an insulated chamber, heated to a precise temperature using internal elements, held at that temperature for a specific duration (soaking), and finally cooled under controlled conditions to achieve the desired material properties.

The specific technology—whether it's a standard box furnace, a vacuum furnace, or an induction furnace—is simply an adaptation of this universal cycle. The key differences lie in how the furnace controls the atmosphere and generates heat to meet the specific needs of the material being processed.

The Universal Four-Step Furnace Cycle

Nearly all thermal processing follows a consistent, logical sequence. Understanding this cycle is the key to understanding how any furnace, including a box furnace, functions.

Step 1: Loading the Furnace

This is the physical placement of the parts, tools, or raw materials into the furnace chamber.

The method can be as simple as opening a door on a standard box furnace or involve an automated, electrically operated elevator for heavy loads in a bottom-loading furnace.

Step 2: Controlling the Atmosphere

Before heating begins, the internal environment of the furnace is prepared. This is one of the most critical differentiators between furnace types.

A standard box furnace often operates in ambient air. However, for materials sensitive to oxidation or contamination, a vacuum is created by pumping out all the oxygen, or the chamber is filled with an inert gas like argon.

Step 3: The Heating Phase

This is where energy is introduced to raise the temperature of the material. The method used to generate this heat is another key distinction between furnace designs.

Most box furnaces use resistance heating, where electrical elements inside the chamber walls glow hot, heating the chamber and the parts inside through radiation and convection.

Other systems, like induction furnaces, use a powerful alternating current in a copper coil to create an electromagnetic field. This field induces electrical currents directly within the conductive metal part, causing it to heat itself from the inside out.

Step 4: Soaking and Cooling

Once the target temperature is reached, the material is often "soaked"—held at that temperature for a set period to ensure the entire part is uniformly heated.

The final cooling step is critical for locking in desired material properties. Cooling can be slow (shutting the furnace off and letting it cool naturally) or rapid, often achieved by cycling pressurized inert gas through the chamber to pull heat away from the part without causing chemical reactions.

How Different Furnaces Adapt the Process

The four-step cycle is the blueprint. The specific type of furnace is the implementation, each optimized for different outcomes.

The Standard Box Furnace

This is the general workhorse. It typically uses resistance heating elements and operates in ambient air. It is ideal for processes where surface oxidation is not a critical concern.

The Vacuum Furnace

The key adaptation here is atmosphere control. By removing virtually all air and reactive gases before heating, it eliminates oxidation, decarburization, and other surface contamination, making it essential for high-performance alloys and medical-grade components.

The Induction Furnace

The key adaptation here is the heating method. By generating heat directly within the material, induction is extremely fast and energy-efficient. It is primarily used for melting metals and for heat-treating specific areas of a part with high precision.

Understanding the Trade-offs

Choosing the right process requires understanding the benefits and limitations of each approach. There is no single "best" furnace, only the best one for a specific application.

Atmosphere vs. Cost

A simple box furnace operating in air is the most cost-effective solution. Introducing vacuum systems or inert gas controls adds significant complexity and cost but is non-negotiable for protecting sensitive materials.

Uniformity vs. Speed

A box furnace with heating elements on all sides provides excellent temperature uniformity, ensuring a large or complex part is heated evenly. Induction heating offers unparalleled speed but can be less uniform across a complex geometry.

Direct vs. Indirect Heating

Resistance elements use indirect heating—they heat the chamber, which then heats the part. This is versatile but less efficient. Induction is a form of direct heating, which is far more energy-efficient but only works on electrically conductive materials.

Making the Right Choice for Your Goal

Your final decision depends entirely on the material you are processing and the outcome you need to achieve.

- If your primary focus is general-purpose heat treatment without strict surface requirements: A standard box furnace using resistance heating in ambient air is the most straightforward and cost-effective solution.

- If your primary focus is preventing any oxidation or contamination on sensitive metals: A vacuum furnace is essential, as its process is designed specifically to remove reactive gases before heating.

- If your primary focus is rapidly melting or heating conductive metals with high efficiency: An induction furnace is the superior choice because it generates heat directly within the material itself.

Ultimately, understanding this core four-step cycle empowers you to see past specific furnace models and select the precise process your material requires.

Summary Table:

| Furnace Type | Key Feature | Primary Use Case |

|---|---|---|

| Standard Box Furnace | Resistance heating in ambient air | General-purpose heat treatment |

| Vacuum Furnace | Atmosphere control (no oxidation) | High-performance alloys, sensitive materials |

| Induction Furnace | Direct, rapid heating of conductive materials | Melting metals, localized heat treatment |

Ready to Optimize Your Thermal Processing?

Understanding the furnace process is the first step. Implementing the right solution is what drives results. KINTEK specializes in lab equipment and consumables, providing the precise furnace technology your laboratory needs.

Whether you require the cost-effectiveness of a standard box furnace, the contamination-free environment of a vacuum furnace, or the rapid heating of an induction system, our experts will help you select the perfect equipment for your material and desired outcome.

Contact us today using the form below to discuss your specific application and discover how KINTEK can enhance your lab's capabilities and efficiency.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout