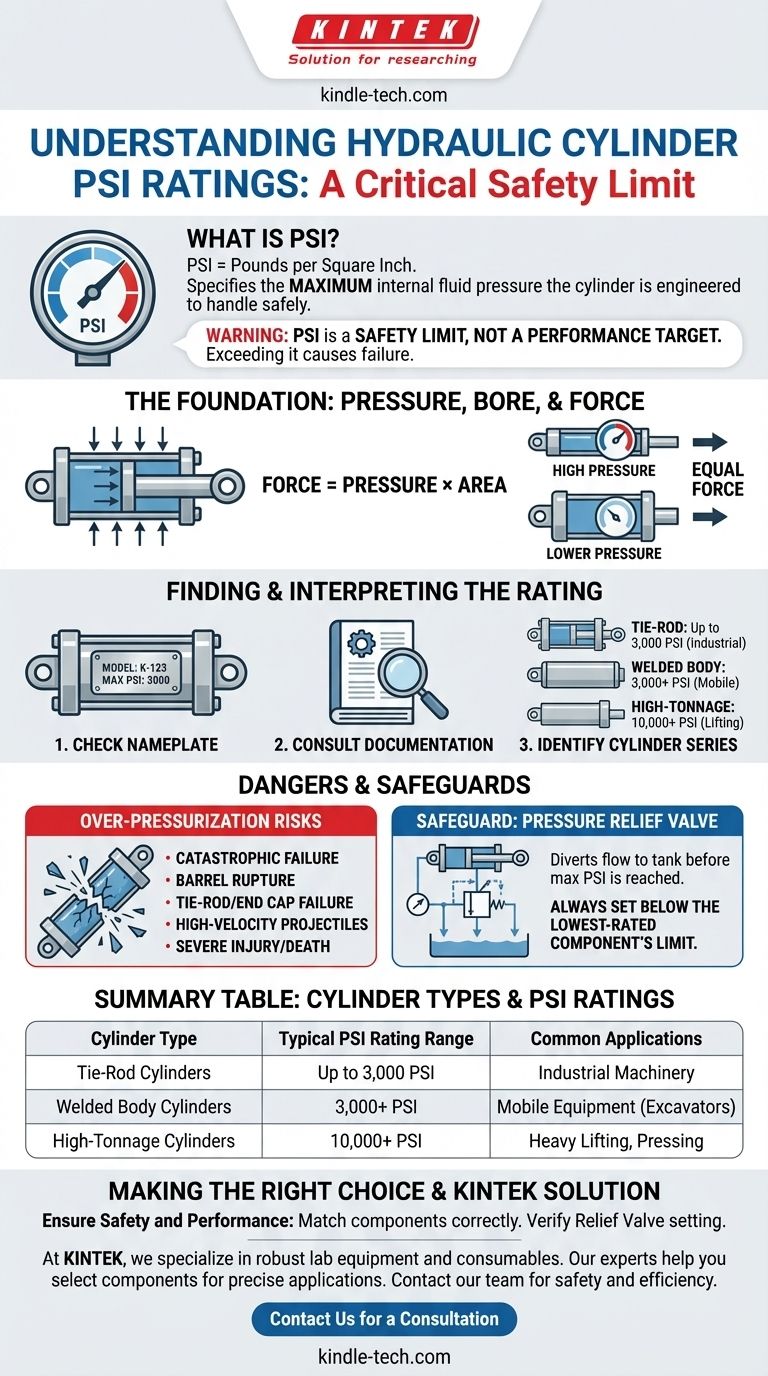

The PSI rating of a hydraulic cylinder, or Pounds per Square Inch, specifies the maximum internal fluid pressure the cylinder is engineered to safely handle during operation. While many standard industrial and mobile cylinders are rated for 2,500 to 3,000 PSI, specialized high-pressure models can be rated for 5,000 PSI, 10,000 PSI, or even higher for specific heavy-duty applications. This rating is the single most important factor for ensuring system safety and performance.

A cylinder's PSI rating is not a performance target; it is a critical safety limit. The core task for any engineer or technician is to ensure the cylinder's maximum pressure rating is comfortably above the hydraulic system's maximum operating pressure, which is typically controlled by a pressure relief valve.

Why Pressure Rating is the Foundation of Cylinder Design

A hydraulic system doesn't create force out of thin air. It uses a pump to create fluid flow, and the resistance to that flow generates pressure. This pressure is the key to how a cylinder produces work.

Defining PSI (Pounds per Square Inch)

PSI is the unit of measure for pressure within the hydraulic system. Think of it as the amount of force the hydraulic fluid exerts on every square inch of the cylinder's internal surfaces.

The Relationship Between Pressure, Bore, and Force

The output force of a cylinder is a direct result of the system pressure acting on the area of its internal piston. The formula is simple but fundamental: Force = Pressure × Area.

This means a cylinder with a larger internal diameter (bore size) can produce the same amount of force with less pressure than a cylinder with a smaller bore.

Nominal vs. Maximum Pressure

It is critical to distinguish between a cylinder's nominal (or working) pressure rating and its maximum (or proof) pressure. Manufacturers often list a nominal rating for continuous duty. The cylinder must be able to withstand occasional pressure spikes above this, but it should never exceed the absolute maximum rating stamped on its data plate.

How to Find and Interpret a Cylinder's PSI Rating

Identifying the correct pressure rating is a non-negotiable step before installing or operating any cylinder. Using an underrated cylinder is one of the most dangerous mistakes in hydraulics.

Checking the Nameplate or Data Tag

The most reliable source is the manufacturer's nameplate or data tag, which is typically stamped or engraved directly onto the cylinder's body or end cap. This tag will list the model number, serial number, and often the maximum pressure rating.

Consulting the Manufacturer's Documentation

If the data tag is missing or illegible, the next step is to use the model number to find the official technical datasheet from the manufacturer. This document will provide a comprehensive list of all specifications, including the definitive pressure rating.

Understanding Cylinder "Series" or "Class"

Experienced professionals can often estimate a cylinder's pressure class by its construction.

- Tie-Rod Cylinders: Common in industrial settings, often rated for up to 3,000 PSI.

- Welded Body Cylinders: Common in mobile equipment (like excavators), typically rated for 3,000 PSI or more due to their robust construction.

- High-Tonnage Cylinders: Used for lifting and pressing, these are compact, ram-style cylinders often rated for 10,000 PSI.

Understanding the Trade-offs and Dangers

Selecting a cylinder is not just about meeting a force requirement; it's about building a safe and efficient system. Understanding the consequences of mismatching pressure is essential.

The Danger of Over-Pressurization

Exceeding a cylinder's maximum PSI rating can lead to catastrophic failure. This can include the cylinder barrel rupturing, the tie-rods stretching or breaking, or the end caps being blown off. These failures release high-pressure fluid and can turn components into high-velocity projectiles, posing a severe risk of injury or death.

The Inefficiency of Over-Specification

Using a 5,000 PSI-rated cylinder in a system that only operates at 1,500 PSI is safe, but it is inefficient. The higher-pressure cylinder will be heavier, larger, and significantly more expensive than a component properly matched to the system's needs.

The Role of the Pressure Relief Valve

The system's pressure relief valve is the ultimate safeguard. This valve should always be set at a pressure below the maximum rating of the lowest-rated component in the system, which is very often the hydraulic cylinder. This ensures that in an overload condition, the valve will divert flow back to the tank before any component can fail.

Making the Right Choice for Your System

Your final selection must be guided by the demands of your system and an unwavering commitment to safety.

- If your primary focus is a standard industrial or mobile application: Select a cylinder with a nominal pressure rating that matches your system's design (e.g., 3,000 PSI) and ensure your relief valve is set below that limit.

- If your primary focus is generating very high force in a compact space: You will need a high-pressure system (5,000-10,000 PSI) and must use cylinders, pumps, hoses, and valves all specifically rated for that pressure.

- If your primary focus is evaluating existing equipment for safety: Your first step is to identify the cylinder's max PSI rating and then verify the system's pressure relief valve is set safely below that number.

Ultimately, treating the PSI rating as an absolute safety boundary is the mark of a true professional.

Summary Table:

| Cylinder Type | Typical PSI Rating Range | Common Applications |

|---|---|---|

| Tie-Rod Cylinders | Up to 3,000 PSI | Industrial Machinery |

| Welded Body Cylinders | 3,000+ PSI | Mobile Equipment (Excavators) |

| High-Tonnage Cylinders | 10,000+ PSI | Heavy Lifting, Pressing |

Ensure the safety and performance of your hydraulic systems. Choosing the right components with the correct pressure ratings is fundamental to preventing catastrophic failure. At KINTEK, we specialize in providing robust lab equipment and consumables, serving the precise needs of laboratories and industrial settings. Our experts can help you select the right components for your specific application requirements. Contact our team today for a consultation and let KINTEK be your partner in safety and efficiency.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What are the methods of infrared spectroscopy? A Guide to Solid, Liquid, and Gas Sample Prep

- What role does a laboratory hydraulic press play in the pre-preparation of TiB2-TiN-WC? Build a Solid Foundation

- What are the methods of cooling the hydraulic system? Choose the Right Cooler for Reliability & Longevity

- How do you explain XRF results? A Guide to Interpreting Elemental Analysis Data

- How is a hydraulic press so strong? Unlocking the Power of Force Multiplication

- What industry uses hydraulic press? Powering Manufacturing from Automotive to Aerospace

- Can you use a hydraulic press for blacksmithing? Unlock the Power of Controlled Force

- What is KBr disc method in IR spectroscopy? A Guide to Solid Sample Analysis