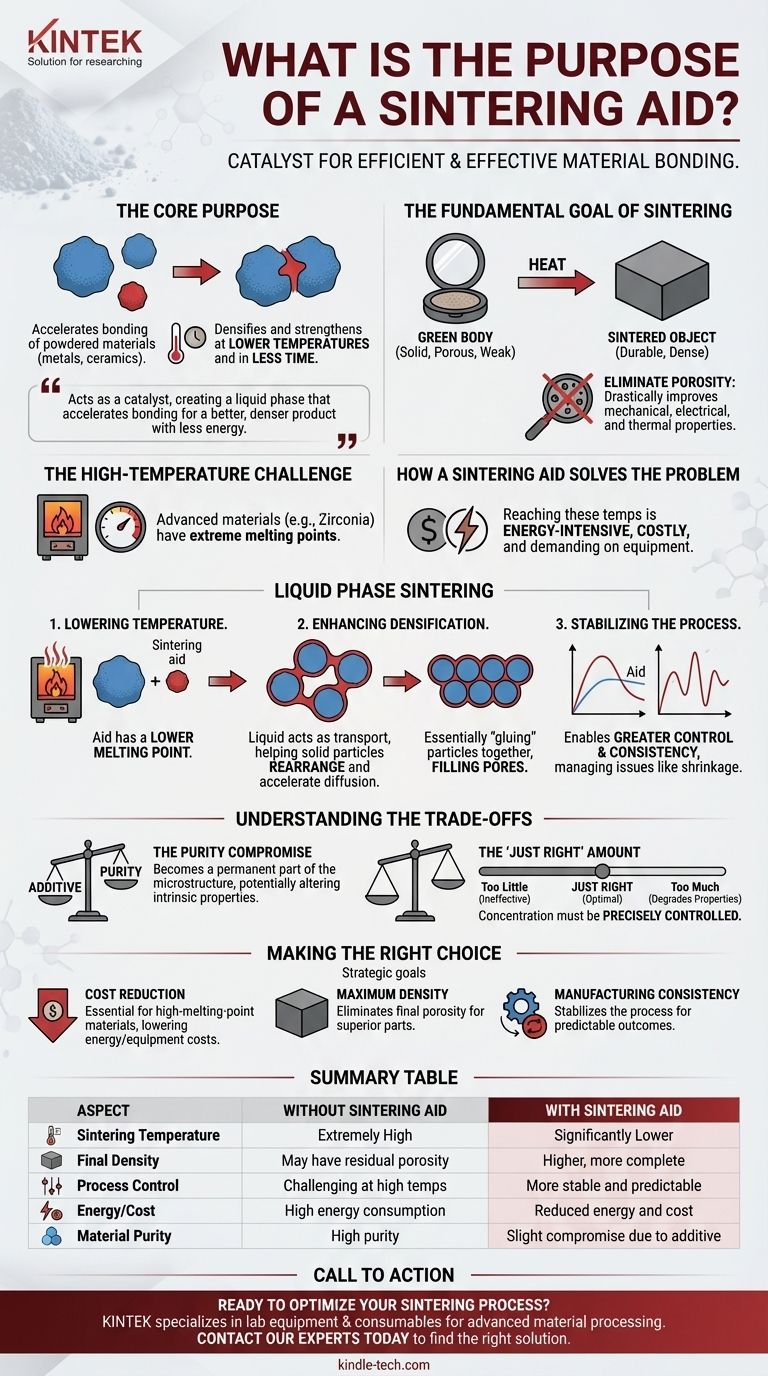

The primary purpose of a sintering aid is to make the process of bonding powdered materials together more efficient and effective. It is an additive that, when mixed with a primary metal or ceramic powder, allows the material to densify and strengthen at a lower temperature and often in less time than would otherwise be required.

The core challenge with high-performance materials is that they require extreme, costly temperatures to sinter properly. A sintering aid acts as a catalyst, creating a liquid phase that accelerates the bonding of solid particles, enabling a better, denser final product with less energy.

The Fundamental Goal of Sintering

To understand why an aid is necessary, we must first understand the core process it is designed to improve. Sintering is a thermal treatment for compacting and forming a solid mass of material from powder.

From Powder to Solid

The process begins with a compressed powder, often called a "green body," which is solid but porous and mechanically weak. Sintering applies heat below the material's melting point to fuse these individual particles together, transforming the fragile powder compact into a durable, dense object.

The Enemy: Porosity

The primary goal of sintering is to eliminate the empty spaces, or pores, between the powder particles. Removing this porosity drastically improves the material's properties, such as its mechanical strength, electrical conductivity, and thermal performance.

The High-Temperature Challenge

Many advanced materials, like technical ceramics (e.g., zirconia) or high-strength metals, have exceptionally high melting points. Reaching the temperatures required to sinter them effectively is energy-intensive, expensive, and places extreme demands on furnace equipment.

How a Sintering Aid Solves the Problem

A sintering aid directly addresses the high-temperature challenge by fundamentally changing how the particles bond. It introduces a mechanism called liquid phase sintering.

Lowering the Sintering Temperature

Most sintering aids are chosen because they have a lower melting point than the primary material. As the furnace heats up, the aid melts first, creating a liquid that coats the solid particles of the main material.

Enhancing Densification

This newly formed liquid acts as a transport medium. It helps the solid particles rearrange themselves into a more tightly packed structure and accelerates the diffusion of atoms, effectively "gluing" the particles together and pulling them closer to fill the pores.

Stabilizing the Process

By enabling sintering at lower, more manageable temperatures, aids provide greater control and consistency. This helps manage common issues like the significant shrinkage that occurs in materials like zirconia, leading to more predictable and reliable final components.

Understanding the Trade-offs

While highly effective, the use of a sintering aid is a calculated engineering decision that involves a critical compromise.

The Purity Compromise

By definition, a sintering aid is an additive. It becomes a permanent part of the final material's microstructure. This can alter the intrinsic properties of the primary material, such as its electrical resistivity, thermal conductivity, or high-temperature performance.

The "Just Right" Amount

The concentration of the sintering aid must be precisely controlled. Too little, and it won't be effective at reducing temperature or improving density. Too much, and the excess secondary material can degrade the final properties of the component, undermining the entire purpose.

Making the Right Choice for Your Goal

Selecting a sintering aid is a strategic decision based on the desired outcome and the limitations of the primary material.

- If your primary focus is cost reduction: A sintering aid is essential for working with high-melting-point materials, as it significantly lowers the energy and equipment costs.

- If your primary focus is achieving maximum density: An aid can help eliminate the final traces of porosity that are difficult to remove with heat and pressure alone, yielding a superior final part.

- If your primary focus is manufacturing consistency: Aids stabilize the sintering process, leading to more repeatable outcomes and better control over the final dimensions and properties.

Ultimately, a sintering aid is a strategic tool for achieving superior material properties with greater efficiency and control.

Summary Table:

| Aspect | Without Sintering Aid | With Sintering Aid |

|---|---|---|

| Sintering Temperature | Extremely High | Significantly Lower |

| Final Density | May have residual porosity | Higher, more complete densification |

| Process Control | Challenging at high temperatures | More stable and predictable |

| Energy/Cost | High energy consumption | Reduced energy and cost |

| Material Purity | High purity | Slight compromise due to additive |

Ready to optimize your sintering process? KINTEK specializes in providing the lab equipment and consumables you need for advanced material processing. Whether you're working with technical ceramics or high-strength metals, our expertise can help you achieve superior results with greater efficiency and control. Contact our experts today to discuss your specific application and find the right solution for your laboratory.

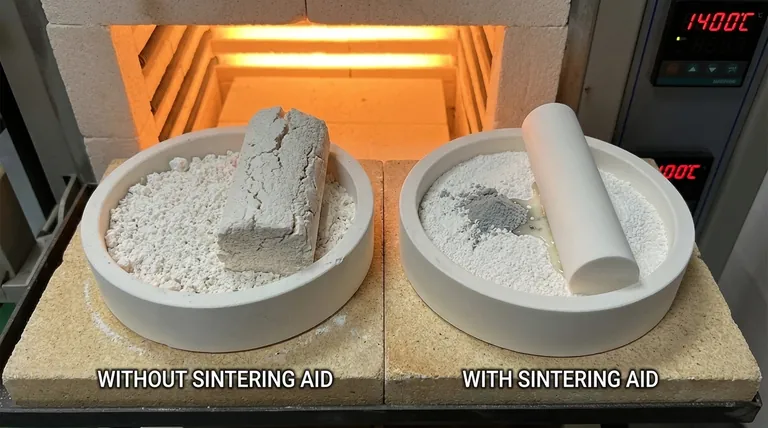

Visual Guide

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Warm Isostatic Press for Solid State Battery Research

- Laboratory CVD Boron Doped Diamond Materials

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What is the maximum operating temperature of alumina? The Critical Role of Purity and Form

- What are the high temperature properties of alumina? Discover Its Stability, Strength, and Limits

- Why are high-purity alumina rods used in LOCA experiments? Simulating Nuclear Fuel Gap and Steam Starvation

- Why is an alumina insulation disk required in a CCPD reactor? Enhance Coating Quality with Floating Potential

- Why are ceramics more resistant to corrosion? Unlock the Secret to Unmatched Chemical Stability