When it comes to heat treating, there is no single temperature range. The process is not a monolithic operation but a category of highly specific thermal treatments. While temperatures can reach as high as 2,400°F (1315°C), the precise temperature required is entirely dependent on the material being treated and the specific physical properties you intend to achieve.

The core principle to understand is that "heat treating" is a goal-oriented process. The correct temperature is not a generic value but a critical variable determined by the specific material and its intended transformation—whether that's to harden, soften, or relieve internal stress.

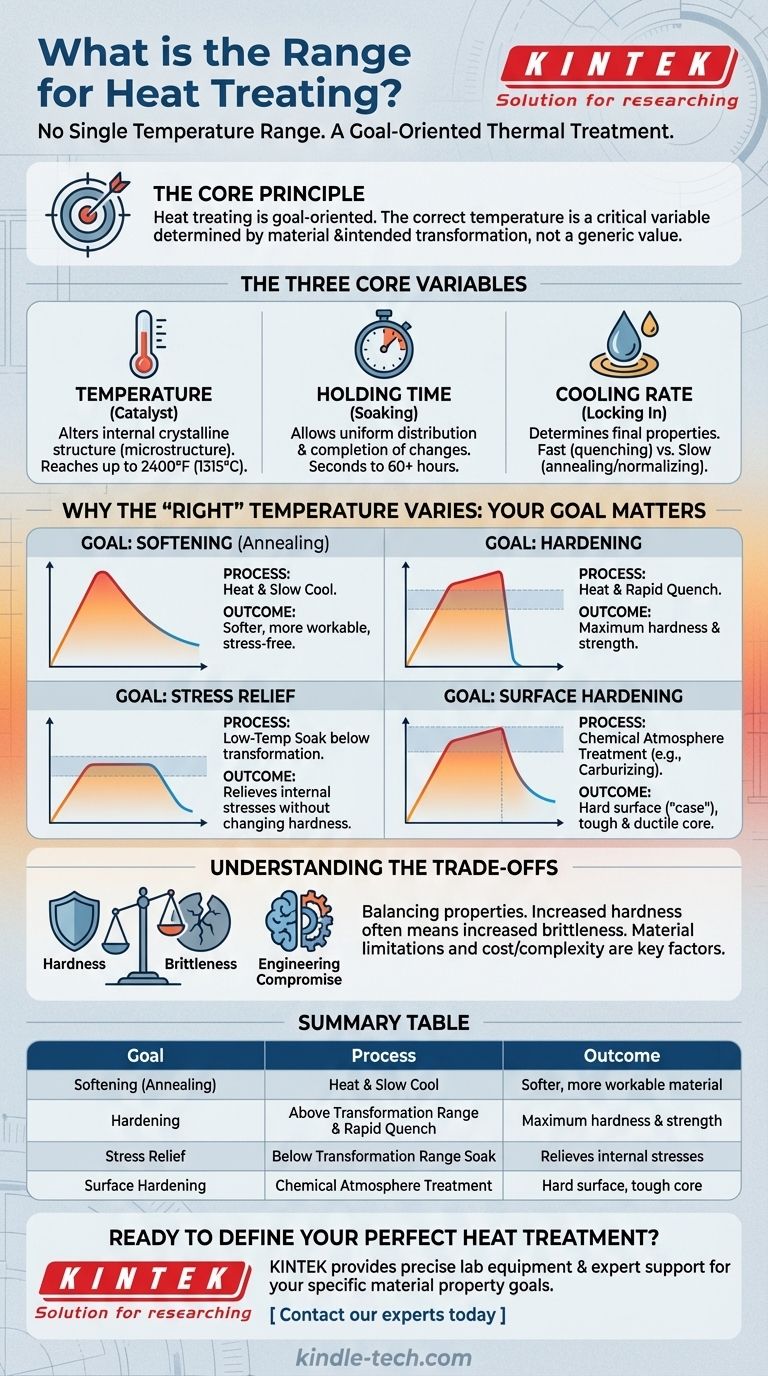

The Three Core Variables of Heat Treatment

Any heat treatment outcome is governed by a precise interplay of three factors. Understanding these variables is the key to understanding why temperature ranges vary so dramatically.

The Role of Temperature

Temperature is the catalyst for change. Heating a metal or polymer to a specific point alters its internal crystalline structure, known as its microstructure.

For many steels, this involves heating above a critical "transformation range" where the material's structure becomes receptive to change. Other processes, like stress relieving, intentionally use temperatures below this range to avoid altering the core properties.

The Importance of Holding Time

Once at the target temperature, the material is held there for a specific duration, a step often called "soaking." This allows the temperature to distribute evenly and the microstructural changes to complete throughout the entire part.

This holding time can range from a few seconds for surface treatments to over 60 hours for large components or specialized annealing processes.

The Critical Factor of Cooling Rate

The final properties of the material are locked in by the cooling process. The rate of cooling—whether it's done rapidly in water or brine (quenching), more slowly in oil, or very slowly in still air (normalizing)—is just as critical as the heating temperature.

A fast cool traps the new, hardened structure, while a slow cool allows a softer, more ductile structure to form.

Why the "Right" Temperature Varies So Drastically

The specific goal of the treatment is the primary factor that dictates the temperature, time, and cooling method. Different goals require fundamentally different thermal profiles.

Goal: Softening (Annealing)

To make a material softer and more workable, an annealing process is used. This involves heating the material to a specific temperature and then cooling it very slowly, allowing the internal structure to become uniform and stress-free.

Goal: Hardening

To achieve maximum hardness and strength, a material is heated above its transformation temperature and then cooled rapidly in a process called quenching. The high temperature creates a specific crystalline structure, and the fast cooling locks it into place.

Goal: Stress Relief

After processes like welding, forming, or heavy machining, a part can contain significant internal stresses. A lower-temperature heat treatment, well below the transformation range, can be applied to relieve these stresses without changing the material's fundamental hardness or strength.

Goal: Surface Hardening (Case Hardening)

Sometimes, only the surface of a part needs to be hard for wear resistance, while the core must remain tough and ductile. Processes like carburizing or nitriding heat the part in a specific chemical atmosphere to change the composition of the surface layer, creating a hard "case."

Understanding the Trade-offs

Choosing a heat treatment process is a matter of engineering compromises. You are always balancing competing properties to achieve the optimal performance for a specific application.

Hardness vs. Brittleness

A very common trade-off is that increasing hardness almost always increases brittleness. A fully hardened part may be extremely resistant to wear but could shatter under sharp impact. This is why a secondary, lower-temperature process called tempering is often performed after hardening to reduce brittleness and increase toughness.

Material Limitations

The specific alloy dictates the possibilities. A plain low-carbon steel cannot be significantly hardened by heat treatment alone because it lacks the necessary alloying elements (like carbon). Every material has a unique set of temperature thresholds and potential outcomes defined by its composition.

Cost and Complexity

Simple processes like stress relief or normalizing are relatively straightforward. In contrast, highly controlled processes like vacuum heat treating or nitriding offer superior results and control but require specialized equipment and significantly increase costs.

Making the Right Choice for Your Goal

To determine the correct heat treatment parameters, you must first define your primary objective.

- If your primary focus is softening a material for forming: You will likely use an annealing process, which involves controlled heating and very slow cooling.

- If your primary focus is achieving maximum surface hardness and wear resistance: You need a case-hardening process like carburizing or nitriding, which modifies the surface chemistry.

- If your primary focus is achieving high strength and hardness throughout a part: You will use a through-hardening process that involves heating above the transformation range followed by a rapid quench.

- If your primary focus is removing internal stress from welding or machining: You will use a stress-relief process at a temperature carefully chosen to be below the material's transformation point.

Ultimately, the temperature is not a range to choose from, but a precise target dictated by your material and your mission.

Summary Table:

| Goal | Typical Temperature Range | Key Process | Outcome |

|---|---|---|---|

| Softening (Annealing) | Varies by material | Heat & slow cool | Softer, more workable material |

| Hardening | Above transformation range | Heat & rapid quench | Maximum hardness & strength |

| Stress Relief | Below transformation range | Low-temperature soak | Relieves internal stresses |

| Surface Hardening | Varies by process | Chemical atmosphere treatment | Hard surface, tough core |

Ready to define the perfect heat treatment for your material and mission?

At KINTEK, we specialize in providing the precise lab equipment and expert support needed to achieve your specific material property goals. Whether you are working on annealing, hardening, or stress relief, our solutions ensure accurate temperature control and reliable results.

Let's discuss your application. Contact our experts today to find the ideal heat treatment solution for your laboratory needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity