At their core, these three heat treatments are methods to control a metal's final properties, but they achieve opposite results. Hardening makes a metal extremely hard and wear-resistant but also brittle. Annealing does the reverse, making a metal soft, ductile, and easy to work with. Tempering is a secondary process performed after hardening to reduce the brittleness and achieve a desired balance of hardness and toughness.

The fundamental difference is one of intent. Annealing is a "reset button" that makes metal as soft as possible. Hardening creates maximum hardness at the cost of extreme brittleness. Tempering is the critical refinement step that trades a small amount of that hardness for a large gain in toughness, making the part useful.

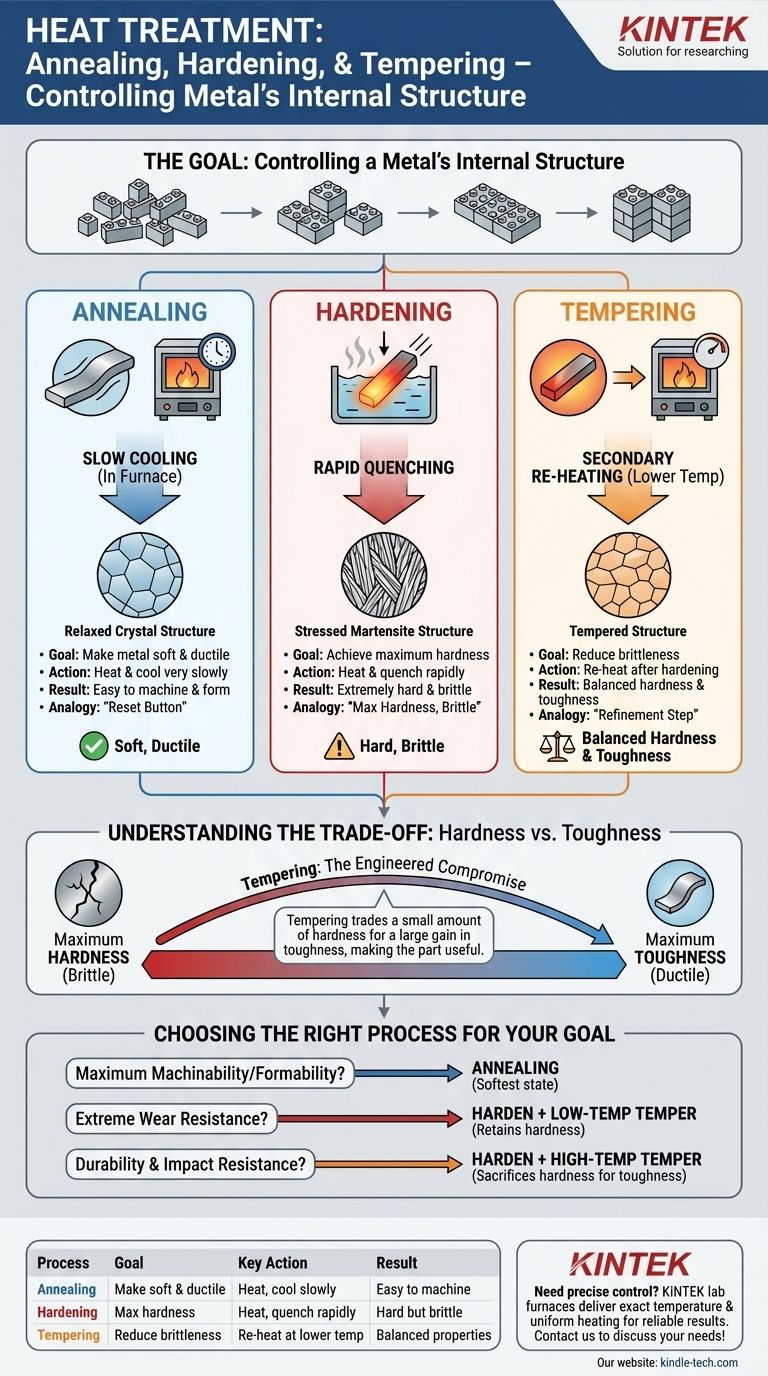

The Goal: Controlling a Metal's Internal Structure

Think of a metal's internal crystal structure as a set of LEGO bricks. Heat treatment gives you the power to take those bricks apart and reassemble them into different configurations, each with unique properties. The speed at which you cool the metal is the most critical factor in determining the final structure.

What is Hardening?

Hardening involves heating a metal like steel above its critical austenitizing temperature (e.g., over 1600°F) and then cooling it very rapidly. This rapid cooling, or quenching, is typically done in oil or water.

This process traps the metal's internal structure in a very hard, stressed, and brittle state known as martensite. The primary goal of hardening is to achieve the maximum possible hardness and wear resistance for a given material.

What is Annealing?

Annealing also involves heating a metal to a high temperature, similar to hardening. However, the crucial difference is the cooling rate. After heating, the metal is cooled as slowly as possible, often by leaving it inside the insulated furnace to cool overnight.

This slow cooling allows the internal crystals to reform in the most relaxed, stress-free state possible. The result is a metal that is soft, ductile, and easy to machine or form. Annealing essentially erases the effects of prior work or hardening.

What is Tempering?

Tempering is a secondary, lower-temperature heating process that is only performed after hardening. A freshly hardened part is often too brittle for any practical application; it would shatter like glass if dropped or struck.

To fix this, the part is re-heated to a precise temperature well below the hardening temperature. This process relieves the internal stresses from quenching and allows some of the brittle martensite to transform into a tougher structure. It makes the metal usable by "dialing back" the brittleness.

Hardening and Tempering: A Two-Step Process

It is critical to understand that hardening and tempering are almost always performed together as a sequence. A part is rarely just "hardened" without also being tempered.

Step 1: The Hardening Quench

The metal is heated and quenched to achieve its maximum potential hardness. At this stage, the part is extremely wear-resistant but dangerously brittle and full of internal stress.

Step 2: The Tempering Refinement

Immediately after quenching, the part is cleaned and put through a tempering cycle. The specific tempering temperature is chosen to produce the final desired balance of properties. A lower tempering temperature preserves more hardness, while a higher tempering temperature sacrifices hardness for a significant gain in toughness.

Understanding the Trade-offs: Hardness vs. Toughness

You cannot maximize every property at once. Heat treatment is an exercise in engineered compromises, primarily between hardness and toughness.

The Brittle Nature of "Hardness"

A fully hardened, untempered part is exceptionally hard and will resist scratching and abrasion. However, it has very low toughness, meaning it cannot absorb impact energy and will fracture easily. This is ideal for a file, which needs to hold a sharp edge, but disastrous for a hammer or an axle.

The Malleable Nature of "Softness"

A fully annealed part has maximum ductility and is very tough. It can be bent, stretched, and deformed without breaking. However, its low hardness means it will not hold an edge, resist wear, or stand up to high loads.

Tempering: The Engineered Compromise

Tempering is the essential bridge between these two extremes. It allows an engineer to start with a fully hardened part and then strategically trade away a small amount of hardness to gain the critical toughness needed for a component to survive in its intended application.

Choosing the Right Process for Your Goal

Your choice depends entirely on the final performance you require from the component.

- If your primary focus is maximum machinability or formability: Annealing is your process. It creates the softest, most stress-free state, making the metal easy to cut or shape.

- If your primary focus is extreme wear resistance and edge retention: Harden the part and follow it with a low-temperature temper. This retains most of the hardness while removing just enough brittleness to prevent catastrophic failure.

- If your primary focus is durability and impact resistance: Harden the part and follow it with a high-temperature temper. This sacrifices significant hardness to create a much tougher and more resilient final component.

By understanding the distinct purpose of each process, you gain precise control over a material's final performance.

Summary Table:

| Process | Goal | Key Action | Result |

|---|---|---|---|

| Annealing | Make metal soft and ductile | Heat and cool very slowly | Easy to machine or form |

| Hardening | Achieve maximum hardness | Heat and quench (cool rapidly) | Hard but brittle |

| Tempering | Reduce brittleness after hardening | Re-heat to a lower temperature | Balanced hardness and toughness |

Need precise control over material properties for your research or production? The right lab furnace is critical for successful heat treatment processes like annealing, hardening, and tempering. At KINTEK, we specialize in high-quality lab furnaces that deliver the exact temperature control and uniform heating your work demands. Let our experts help you select the perfect equipment to achieve consistent, reliable results. Contact KINTEK today to discuss your laboratory's specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What role does a muffle furnace play in converting loaded activated carbon into an active catalyst? Optimize Your Catalyst Activation

- What role does a high-temperature box furnace play during the re-austenitization of 17-4 PH? Transform SLM Performance

- What role do laboratory ovens and solvent cleaning steps play in the regeneration of NbOx-SiO2 catalysts?

- What are the disadvantages of heat treatment of metals? Managing the Risks of Distortion and Brittleness

- What is the role of a high-temperature quenching furnace in Fe-Cr-Ni-Mn-N steel? Achieve Single-Phase Austenite.

- What is the muffle furnace 1800 degree? High-Temp Precision for Advanced Materials

- What is a muffle furnace used for in a lab? Achieve Clean, High-Temperature Processing

- Why is a precision laboratory oven required for zirconium dioxide nanoparticle synthesis? Master Structural Integrity