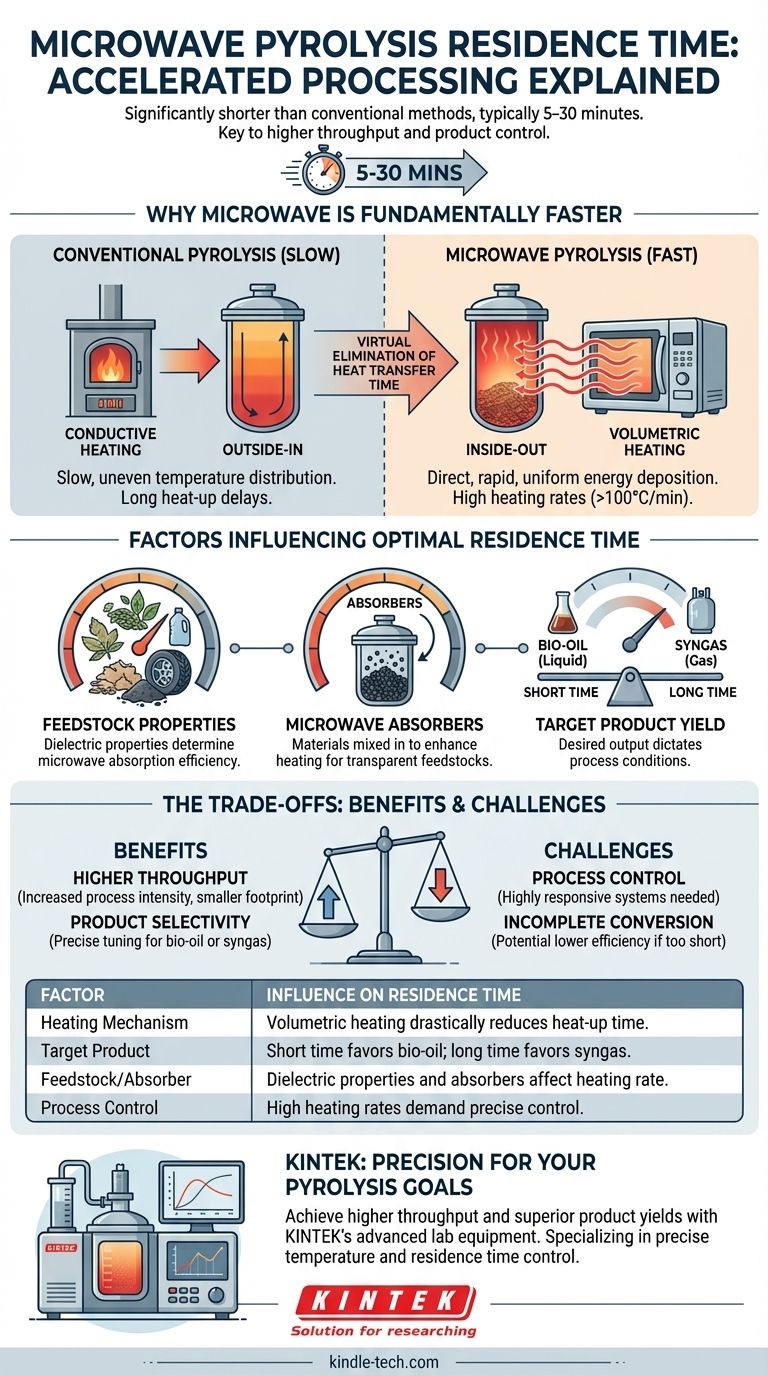

In short, the residence time for microwave pyrolysis is significantly shorter than for conventional methods, typically ranging from 5 to 30 minutes. This accelerated processing is a direct result of the unique way microwaves transfer energy, which allows for extremely rapid and uniform heating of the feedstock.

The core advantage of microwave pyrolysis is its speed. By heating the material volumetrically—from the inside out—it drastically reduces the time needed to reach reaction temperatures, enabling shorter residence times, which in turn leads to higher throughput and different product distributions compared to slower, conventional heating.

The Role of Residence Time in Pyrolysis

Residence time is the average duration that a particle of feedstock remains within the high-temperature reaction zone of the pyrolysis reactor. It is a critical parameter that directly governs the outcome of the process.

Defining the Reaction Pathway

Once the initial breakdown of the feedstock occurs (primary decomposition), the resulting hot vapors can undergo further reactions (secondary cracking) if they remain in the hot zone.

A short residence time quickly removes these vapors from the reactor. This minimizes secondary cracking and tends to favor the production of liquid bio-oil.

A long residence time keeps the vapors in the hot zone, promoting secondary cracking. This breaks down larger, condensable molecules into smaller, non-condensable gases, thus increasing the syngas yield at the expense of bio-oil.

Why Microwave Pyrolysis is Fundamentally Faster

The short residence time of microwave pyrolysis is not an arbitrary choice; it is a direct consequence of its heating mechanism, which fundamentally differs from conventional pyrolysis.

The Mechanism: Volumetric vs. Conductive Heating

Conventional pyrolysis relies on conduction and convection. Heat is applied to the outside of the reactor and must slowly travel inward to heat the feedstock. This process is slow and often results in an uneven temperature distribution.

Microwave pyrolysis uses volumetric heating. Microwaves penetrate the feedstock and deposit energy directly and simultaneously throughout its entire volume. This is analogous to how a microwave oven heats food from the inside out, whereas a conventional oven heats it from the outside in.

Impact on Heating Rate

This direct energy deposition results in exceptionally high heating rates, often exceeding 100°C per minute. The feedstock reaches the target pyrolysis temperature almost instantly, eliminating the long heat-up delays characteristic of conventional systems.

Consequence for Residence Time

Because the time required for heat transfer is virtually eliminated, the overall residence time is now dominated by the time needed for the chemical reactions to complete. This allows for a much more compact and efficient reactor design with significantly higher throughput.

Factors Influencing Residence Time

While microwave pyrolysis is inherently fast, the optimal residence time is not a single number. It is adjusted based on several key factors.

Feedstock Properties

The type of material being processed (e.g., biomass, plastics, tires) is critical. Its dielectric properties determine how effectively it absorbs microwave energy. Materials that absorb microwaves well will heat faster, potentially allowing for shorter residence times.

Use of Microwave Absorbers

For feedstocks that are transparent to microwaves (like many dry plastics or biomass), a microwave-absorbent material such as silicon carbide or biochar is often mixed in. This absorber heats up rapidly and transfers that heat to the feedstock, ensuring efficient pyrolysis. The amount and type of absorber influence the required residence time.

Target Product Yield

The desired output dictates the process conditions. If the goal is to maximize bio-oil, a shorter residence time is used to preserve the primary vapor products. If maximizing syngas is the objective, a longer residence time is employed to encourage secondary cracking.

Understanding the Trade-offs

The short residence time is a major advantage, but it also presents specific engineering considerations.

Benefit: Higher Throughput

The most significant benefit is increased process intensity. A smaller microwave reactor can process the same amount of material as a much larger conventional reactor in the same amount of time, reducing the system's physical footprint and capital cost.

Benefit: Product Selectivity

The precise control and rapid heating allow operators to "tune" the process for specific products. Fast pyrolysis conditions (short residence time) are easily achieved to maximize liquid yields.

Challenge: Process Control

The speed of the process demands highly responsive and precise control systems. Any fluctuation in feedstock feed rate or microwave power can have an immediate impact on the product outcome, leaving little room for error.

Challenge: Incomplete Conversion

If the residence time is too short for the given temperature and feedstock, the pyrolysis reactions may not go to completion. This can result in lower overall conversion efficiency and a higher char yield than desired.

Making the Right Choice for Your Goal

Optimizing residence time is essential for achieving your specific process objective. It is the primary lever you can pull to steer the chemical outcome of the reaction.

- If your primary focus is maximizing liquid bio-oil yield: Target a short residence time to rapidly quench the pyrolysis vapors and prevent them from cracking into lighter gases.

- If your primary focus is maximizing syngas production: Employ a longer residence time and/or higher temperature to promote the secondary cracking of oil vapors into permanent gases.

- If your primary focus is achieving high process throughput: Leverage the inherently short residence time of microwave pyrolysis as a key economic advantage over slower, conventional methods.

Ultimately, controlling residence time is how you transform microwave pyrolysis from a simple heating method into a precise chemical manufacturing tool.

Summary Table:

| Factor | Influence on Residence Time |

|---|---|

| Heating Mechanism | Volumetric microwave heating drastically reduces heat-up time vs. conductive heating. |

| Target Product | Short time favors bio-oil; long time favors syngas. |

| Feedstock/Absorber | Dielectric properties and use of absorbers (e.g., biochar) affect heating rate. |

| Process Control | High heating rates demand precise control to avoid incomplete conversion. |

Ready to optimize your pyrolysis process with precise temperature and residence time control? KINTEK specializes in advanced lab equipment, including pyrolysis systems, to help you achieve higher throughput and superior product yields. Contact our experts today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What is the difference between regeneration and reactivation of carbon? Clarifying Key Terminology

- What is biochar obtained from the pyrolysis? A Key Product of Biomass Conversion

- What is the efficiency of a rotary kiln? Achieve Optimal Performance for Your Process

- What technical requirements must high-temperature industrial kilns meet for the chlorination roasting of quartz sand?

- What is the process of pyrolysis reactor? Turn Waste into Valuable Resources with Thermal Decomposition

- What are rotary kilns used for? Achieve High-Temperature Material Processing

- Can you regenerate activated charcoal? The Truth About Reusing Spent Carbon Filters

- How do you reactivate carbon? Restore Adsorption Capacity & Save Costs