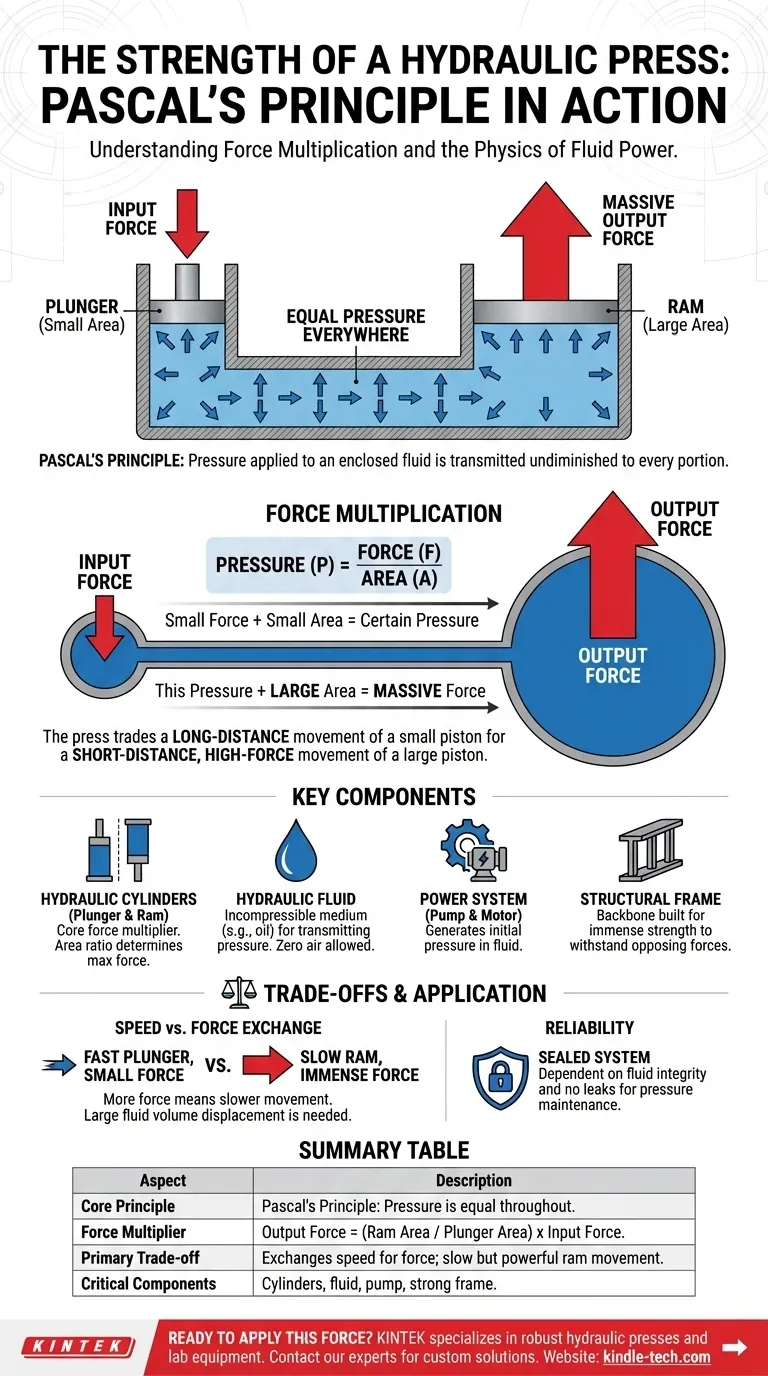

The strength of a hydraulic press does not come from the machine itself, but from a fundamental law of physics known as Pascal's Principle. By applying a small force to a small piston (the plunger), the press transmits that pressure through an incompressible fluid to a much larger piston (the ram), massively multiplying the initial force.

The core insight is that a hydraulic press is a force multiplier. It trades a long-distance movement of a small piston for a short-distance, high-force movement of a large piston, allowing it to generate immense power from a relatively small input.

The Core Principle: Force Multiplication in Action

To understand the source of a hydraulic press's strength, you must first understand the physics governing confined fluids. The entire design is an elegant application of a single, powerful concept.

Pascal's Principle: The Foundation

The system is built on Pascal's Principle, which states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, the pressure everywhere inside the hydraulic system is the same.

Two Cylinders, One System

A hydraulic press uses two interconnected cylinders of different sizes, each with a piston. The smaller cylinder is called the Plunger, and the larger one is called the Ram. Both are filled with hydraulic fluid, typically oil.

When a force is applied to the Plunger, it creates pressure in the fluid. According to Pascal's Principle, this exact same pressure is then exerted on the Ram.

How a Small Push Creates Massive Force

Here is where the force multiplication occurs. The formula for pressure is Pressure = Force / Area.

Since the pressure is equal on both pistons, the force on each is determined by its surface area. If the Ram has a surface area 100 times greater than the Plunger, it will exert a force 100 times greater than the force applied to the Plunger.

This relationship is the secret to the hydraulic press's incredible strength. A modest force from a small pump can be converted into tons of output force at the Ram.

The Key Components That Enable This Strength

While the principle is simple, several critical components work together to contain and direct this force effectively.

Hydraulic Cylinders (Plunger and Ram)

These are the heart of the system where the force multiplication happens. The ratio of their areas directly determines the maximum force multiplier of the press.

Hydraulic Fluid

The fluid, usually a specialized oil, acts as the medium for transmitting pressure. It must be incompressible to work efficiently; any air in the system would compress and absorb pressure, drastically reducing the press's strength.

The Power System (Pump and Motor)

A pump, driven by a motor, is what applies the initial force to the Plunger. This system generates the initial pressure in the hydraulic fluid that is then transmitted to the Ram.

The Structural Frame

The frame is the backbone of the press. It must be engineered with immense strength and rigidity to withstand the massive opposing forces generated by the Ram without bending or failing.

Understanding the Trade-offs

The immense force generated by a hydraulic press is not without its compromises. Understanding these trade-offs is crucial for its proper application.

The Speed-for-Force Exchange

The primary trade-off is speed for force. While the Ram exerts a massive force, it moves a very short distance.

To move the large Ram a certain distance, a much larger volume of fluid is required. This means the small Plunger must travel a significantly longer distance to displace that fluid, resulting in a slow but powerful output stroke.

Reliance on a Sealed System

The strength of the press is entirely dependent on the integrity of the hydraulic system. Any fluid leaks will cause a loss of pressure and a failure to generate the desired force.

Control System Complexity

While the core concept is simple, precisely controlling the immense forces requires sophisticated hydraulic control valves and power units. These systems manage the direction, speed, and pressure of the fluid to ensure safe and accurate operation.

Making the Right Choice for Your Goal

Understanding this principle allows you to see how the design of a hydraulic press is directly tied to its intended application.

- If your primary focus is generating maximum force: The key is to maximize the area ratio between the Ram and the Plunger.

- If your primary focus is operational speed: You must accept that a lower force multiplier (a smaller area ratio) is necessary for a faster ram travel speed.

- If your primary focus is reliability and precision: The integrity of the hydraulic seals, the quality of the fluid, and the sophistication of the control valves are the most critical factors.

By manipulating the area of two pistons, a hydraulic press turns simple fluid mechanics into a tool of immense industrial power.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Pascal's Principle: Pressure in a confined fluid is transmitted equally. |

| Force Multiplier | Force on the Ram = (Ram Area / Plunger Area) x Input Force. |

| Primary Trade-off | Exchanges speed for immense force; the Ram moves slowly but powerfully. |

| Critical Components | Hydraulic cylinders, incompressible fluid, pump/motor, strong structural frame. |

Ready to apply this immense force to your projects?

At KINTEK, we specialize in designing and supplying robust hydraulic presses and lab equipment that leverage this powerful principle. Whether your goal is maximum force, operational speed, or precision control, our expertise ensures you get the right solution for your laboratory or industrial needs.

Contact our experts today to discuss how a KINTEK hydraulic press can enhance your productivity and deliver the power you require.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.