At its core, the synthesis of carbon nanotubes (CNTs) via the Chemical Vapor Deposition (CVD) method is a process of "growing" tubes from the atom up. It involves introducing a carbon-containing gas into a high-temperature chamber, where a metal catalyst breaks down the gas. The resulting carbon atoms then assemble on a substrate, forming the distinct cylindrical structure of a nanotube.

Catalytic CVD has become the dominant industrial method for producing CNTs because it offers an unparalleled balance of structural control and cost-effectiveness. However, this control comes with significant operational challenges, primarily related to high temperatures and the management of hazardous materials.

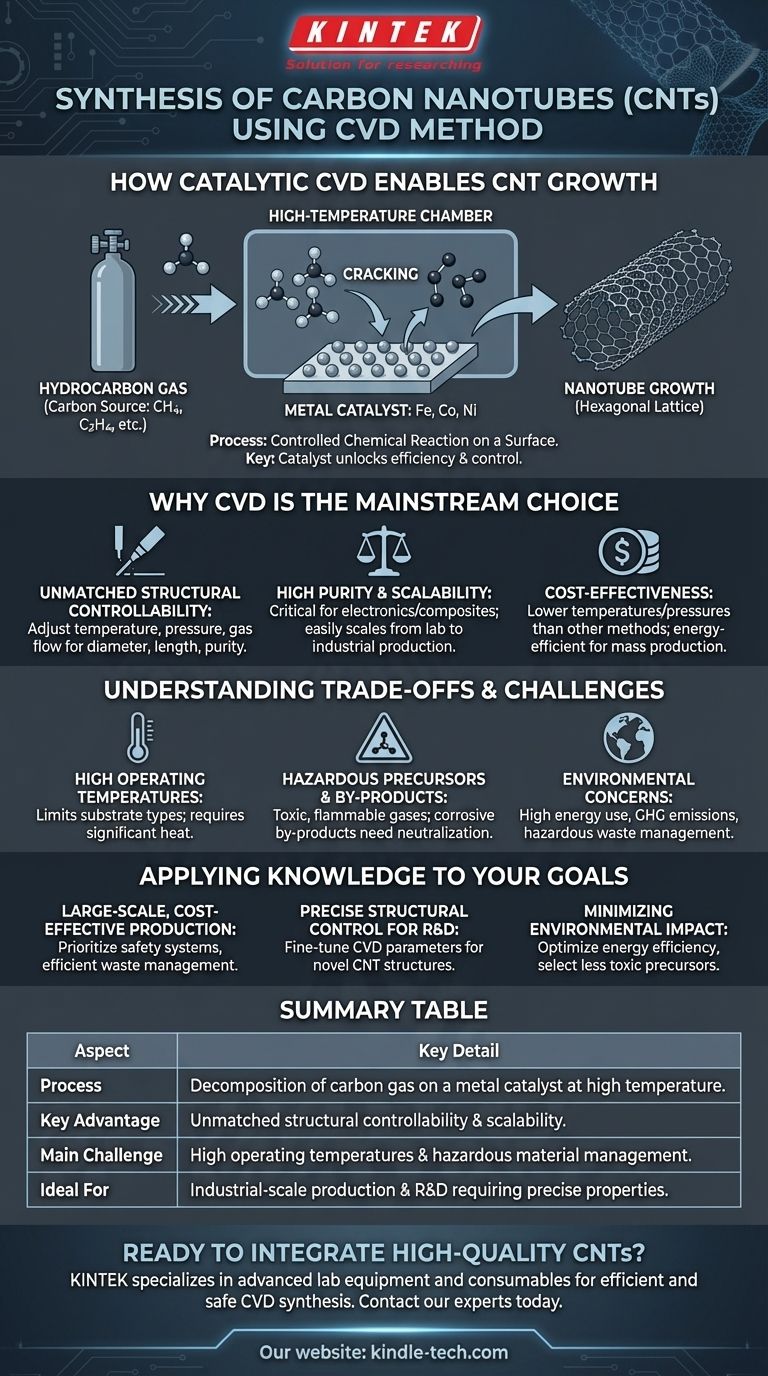

How Catalytic CVD Enables CNT Growth

The CVD process is not simply a deposition; it is a controlled chemical reaction on a surface. For CNTs, the inclusion of a catalyst is the key that unlocks the entire process, making it more efficient and controllable.

The Role of the Carbon Source

The process begins by introducing a hydrocarbon gas, such as methane, ethylene, or acetylene, into a reaction chamber. This gas serves as the "feedstock" or raw material, providing the carbon atoms needed to build the nanotubes.

The Function of the Metal Catalyst

Before the reaction starts, a substrate is prepared with a thin layer of metal catalyst nanoparticles, typically iron, cobalt, or nickel. At high temperatures, these catalyst particles are where the action happens. They effectively "crack" the hydrocarbon gas, absorbing the carbon atoms.

The Mechanism of Growth

Once the catalyst nanoparticle becomes saturated with carbon, the carbon begins to precipitate out. This precipitation occurs in a highly organized way, forming the hexagonal lattice of a carbon nanotube. The nanotube continues to grow as long as the catalyst remains active and the carbon source is supplied.

Why CVD is the Mainstream Choice for CNTs

While other methods like arc-discharge and laser ablation exist, CVD is widely favored for both research and commercial production due to a combination of practical advantages.

Unmatched Structural Controllability

The defining advantage of CVD is control. By carefully adjusting process parameters like temperature, pressure, gas flow rates, and gas concentration, operators can influence the final properties of the CNTs, such as their diameter, length, and purity.

High Purity and Scalability

CVD allows for the synthesis of high-purity CNTs, which is critical for applications in electronics and composites. More importantly, the process is highly scalable, allowing for the transition from lab-scale experiments to large-volume industrial production more easily than other methods.

Cost-Effectiveness

Compared to the high-energy requirements of laser ablation or arc-discharge, catalytic CVD can operate at lower temperatures and pressures. This makes it a more energy-efficient and, therefore, cost-effective method for mass production.

Understanding the Trade-offs and Challenges

No technical process is without its drawbacks. An objective assessment of CVD requires acknowledging its significant challenges, which are primarily centered on safety and environmental impact.

High Operating Temperatures

Even with a catalyst lowering the reaction temperature, the process still requires significant heat. These high temperatures can limit the types of substrates that can be used, as many materials may become thermally unstable.

Hazardous Precursors and By-products

Many of the chemical precursors (the carbon-source gases) are highly toxic, flammable, or dangerous. Furthermore, the chemical reactions can produce toxic and corrosive by-products that must be neutralized, adding complexity and cost to the operation.

Environmental and Ecotoxicity Concerns

The synthesis process is the primary source of potential ecotoxicity in the CNT life cycle. This stems from high energy consumption, greenhouse gas emissions, and the material consumption associated with both the process itself and the neutralization of its hazardous waste streams.

Applying This Knowledge to Your Goals

Your approach to using CVD should be dictated by your end goal. Understanding the method's strengths and weaknesses allows you to align your strategy for the best outcome.

- If your primary focus is large-scale, cost-effective production: CVD is the clear industry choice, but you must prioritize investment in robust safety systems and efficient waste stream management.

- If your primary focus is precise structural control for R&D: The fine-tunability of CVD parameters makes it the ideal platform for experimenting with and developing novel CNT structures for specific applications.

- If your primary focus is minimizing environmental impact: Your efforts should center on optimizing for energy efficiency and selecting the least toxic precursors possible, as these factors represent the main liabilities of the CVD process.

By understanding both its powerful capabilities and its inherent challenges, you can effectively leverage the CVD method to achieve your specific material synthesis goals.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Decomposition of carbon gas on a metal catalyst at high temperature |

| Key Advantage | Unmatched structural controllability and scalability |

| Main Challenge | High operating temperatures and hazardous material management |

| Ideal For | Industrial-scale production and R&D requiring precise CNT properties |

Ready to integrate high-quality CNTs into your research or production line? KINTEK specializes in providing the advanced lab equipment and consumables necessary for efficient and safe CVD synthesis. Our expertise ensures you achieve the precise structural control and purity your projects demand. Contact our experts today to discuss how we can support your laboratory's specific needs in nanotechnology and materials science.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is a three-zone horizontal hot-wall CVD furnace used for MOCVD Al2TiO5 coatings? Master Precise Coating Uniformity

- How does applying an amorphous carbon layer via CVD affect electro-Fenton catalysts? Enhance H2O2 Selectivity Today

- What is the purpose of using metal catalyst substrates in graphene manufacturing? Lower Thermal Energy Thresholds

- What are the key functions of the high-temperature vacuum or atmosphere reaction retort? Maximize CVD Coating Success

- What is Metal-organic CVD (MOCVD) and what are its applications in CMOS? Enhance Your Semiconductor Precision

- What hardware is used in the carbon nanotube (CNT) modification process? Essential Tools for Li-ion Anode Innovation

- Why is it necessary to maintain independent heating for precursor delivery lines and reactor walls during the ALD process?

- What is the mechanism of sputtering in magnetron? A Guide to Efficient Thin Film Deposition