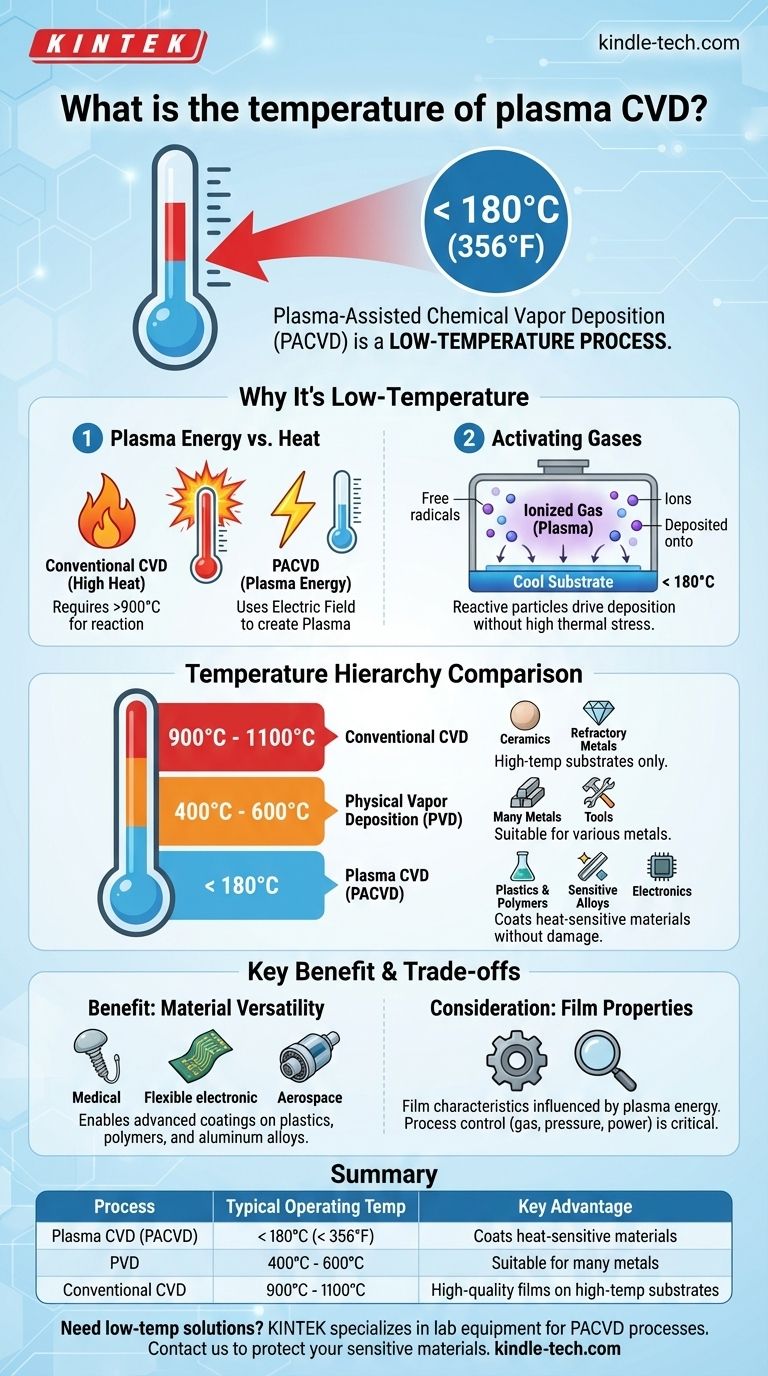

In short, Plasma-Assisted Chemical Vapor Deposition (PACVD) is a low-temperature process. It is specifically designed to operate at temperatures below 180°C (356°F). This remarkably low thermal requirement is its defining characteristic and primary advantage over other deposition methods.

The core takeaway is that PACVD uses energy from plasma, not high heat, to drive the chemical reactions needed for film deposition. This fundamental difference allows for the coating of heat-sensitive materials that would be damaged or destroyed by conventional CVD or even PVD processes.

Why Plasma CVD is a Low-Temperature Process

The "plasma" in PACVD is the key to its low-temperature operation. Instead of relying solely on thermal energy to break down precursor gases, it uses an energized field to create a state of matter called plasma.

The Role of Plasma Energy

In a conventional thermal CVD process, extremely high temperatures (often over 900°C) are needed to give gas molecules enough energy to react and form a solid film on a substrate.

PACVD bypasses this requirement by using an electric field to ionize the precursor gases. This creates a plasma filled with highly reactive ions and free radicals.

Activating Gases Without Extreme Heat

These reactive particles in the plasma have more than enough chemical energy to react and deposit onto the substrate surface, even when the substrate itself remains cool.

The energy for the reaction is supplied directly to the gas molecules by the plasma field, not indirectly by heating the entire chamber and the component being coated.

Deposition Without Thermal Stress

Because the substrate does not need to be heated to high temperatures, PACVD can deposit high-quality films without causing thermal damage, warping, or altering the properties of the underlying material. This is a critical advantage for many modern engineering applications.

How Plasma CVD Compares to Other Methods

Understanding the temperature hierarchy of deposition processes clarifies why PACVD is chosen for specific applications. It occupies the lowest end of the temperature spectrum.

Versus Conventional CVD

Conventional Chemical Vapor Deposition (CVD) is a high-temperature process, often requiring 900°C to 1100°C. This severely limits its use to materials that can withstand extreme heat, such as ceramics or specific refractory metals.

Versus Physical Vapor Deposition (PVD)

Physical Vapor Deposition (PVD) operates at much lower temperatures than conventional CVD, typically in the 400°C to 600°C range. While this makes it suitable for many metals, it is still too hot for polymers, plastics, and certain sensitive alloys.

The Clear Temperature Advantage

With an operating temperature below 180°C, PACVD is significantly cooler than both PVD and conventional CVD. This opens up a vast range of possibilities for coating materials that were previously considered "uncoatable."

Understanding the Trade-offs

While the low processing temperature is a significant benefit, it's essential to understand the context of the application. The choice of a deposition technology is always a balance of process parameters and desired outcomes.

The Benefit: Material Versatility

The primary advantage is the ability to apply advanced coatings to a wide variety of heat-sensitive substrates. This includes plastics, polymers, and aluminum alloys, which are crucial in the electronics, medical, and aerospace industries.

The Consideration: Film Properties

The properties of a deposited film—such as its density, adhesion, and internal stress—are influenced by the energy of the deposition process. The unique plasma environment of PACVD produces films with specific characteristics that may differ from those created at higher temperatures.

Process control is therefore critical. Engineers must carefully tune the plasma parameters (gas mixture, pressure, power) to achieve the desired film quality and performance on the cooler substrate.

Making the Right Choice for Your Application

Selecting the correct deposition technology depends entirely on the material of your substrate and your final performance goals.

- If your primary focus is coating heat-sensitive materials like polymers, plastics, or certain alloys: PACVD is the definitive choice due to its sub-180°C operating temperature.

- If your primary focus is coating a robust material that can withstand high temperatures: Conventional CVD or PVD are viable options, with the final choice depending on the specific coating characteristics required.

- If your primary focus is finding a middle ground for metallic substrates: PVD offers a good balance, operating at a lower temperature than conventional CVD but still higher than PACVD.

Ultimately, understanding the thermal limitations of your substrate is the critical first step in selecting a deposition technology that ensures both component integrity and coating performance.

Summary Table:

| Process | Typical Operating Temperature | Key Advantage |

|---|---|---|

| Plasma CVD (PACVD) | < 180°C (< 356°F) | Coats heat-sensitive materials (plastics, polymers) |

| Physical Vapor Deposition (PVD) | 400°C - 600°C | Suitable for many metals |

| Conventional CVD | 900°C - 1100°C | High-quality films on high-temp substrates |

Need to coat a heat-sensitive material without causing damage? KINTEK specializes in lab equipment and consumables, providing solutions for low-temperature Plasma CVD processes. Our expertise ensures you can apply high-performance coatings to polymers, plastics, and sensitive alloys, preserving your substrate's integrity. Let our team help you select the right equipment for your specific application. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- Is DLC coating scratch proof? Discover the Exceptional Scratch Resistance of DLC Coatings

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the role of plasma in PECVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the Pacvd method? A Guide to Low-Temperature, High-Performance Coatings

- What is plasma chemical vapor deposition? A Low-Temperature Thin Film Coating Solution

- What temperature is DLC applied? Achieve Superior Coatings Without Compromising Substrate Integrity

- How does plasma enhance CVD? Unlock Low-Temperature, High-Quality Film Deposition

- What are the different types of plasma used in PECVD? Choose Between DC, RF, and Microwave Plasma Sources