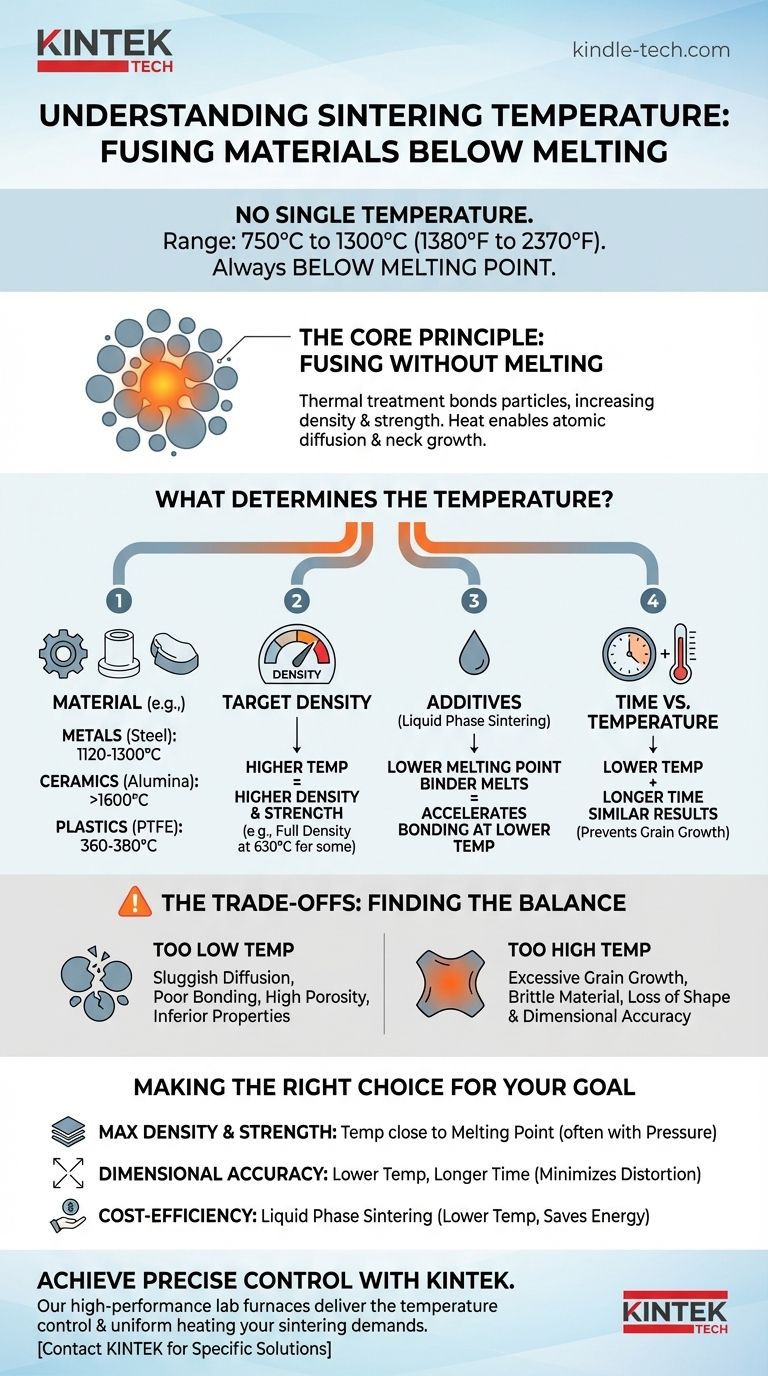

In practice, there is no single temperature for sintering. The process typically operates within a broad range of 750°C to 1300°C (1380°F to 2370°F) for common metals and ceramics, but this is highly dependent on the specific material being processed and the desired final characteristics of the part. The key is that the temperature must always remain below the material's actual melting point.

Sintering temperature is not a fixed number but a critical process variable. The goal is to heat a material just enough to enable atoms to fuse particles together, increasing density and strength, without causing it to melt and lose its shape.

The Core Principle: Fusing Without Melting

Sintering is a thermal treatment applied to a powder compact to impart strength and integrity. The process bonds particles together, leading to densification and the removal of pores left over from the initial compaction stage.

Temperature as the Driving Force

Heat provides the necessary energy for atomic diffusion. At the sintering temperature, atoms at the contact points between powder particles become mobile. They migrate across particle boundaries, causing the individual particles to fuse and "necks" to grow between them.

The "Just Below Melting" Rule

The process is fundamentally different from casting. The temperature must be high enough to allow significant diffusion but low enough to ensure the material remains in a solid state. If the temperature reaches the melting point, the part would liquefy, lose its shape, and the process would fail.

What Determines the Sintering Temperature?

The precise temperature is a carefully calculated variable that depends on several interacting factors.

The Material Being Processed

Every material has a unique temperature at which atomic diffusion becomes significant.

- Metals: Ferrous alloys are often sintered between 1120°C and 1300°C.

- Ceramics: Materials like alumina require much higher temperatures, often exceeding 1600°C.

- Plastics: Polymers like PTFE (Teflon) are sintered at much lower temperatures, typically around 360°C to 380°C.

The Desired Final Density

Higher temperatures generally promote faster diffusion and lead to a denser final part with lower porosity. For applications requiring maximum mechanical strength, operators often push the temperature as high as is safely possible. One specific reference noted achieving full density at 630°C for a particular material, illustrating how the target dictates the temperature.

The Use of Additives (Liquid Phase Sintering)

Sometimes, a powder with a lower melting point is mixed into the primary material. During heating, this additive melts and becomes a liquid phase that flows into the pores between the solid particles. This liquid accelerates diffusion and bonding, allowing for successful sintering at a lower overall temperature, which saves energy and time.

Understanding the Trade-offs

Choosing the right temperature is a balancing act. The consequences of a poor selection are significant.

Temperature Too Low

If the temperature is insufficient, atomic diffusion will be sluggish. This results in poor bonding between particles, high residual porosity, and a final product with inferior mechanical properties like low strength and hardness.

Temperature Too High

Exceeding the optimal temperature introduces other risks, even if you stay below the melting point. The primary danger is excessive grain growth. This can make the material brittle and reduce its strength. It can also lead to a loss of dimensional accuracy as the part slumps or warps.

The Role of Time

Sintering is a function of both temperature and time. A similar level of densification can often be achieved by using a lower temperature for a longer period. This trade-off is often used to prevent unwanted grain growth in high-performance materials.

Making the Right Choice for Your Goal

The optimal sintering temperature is always tied to a specific manufacturing objective.

- If your primary focus is maximum density and strength: You will likely use a temperature close to the material's melting point, possibly combined with pressure (a process known as "hot isostatic pressing").

- If your primary focus is dimensional accuracy for complex shapes: You may use a slightly lower temperature and a longer hold time to minimize the risk of distortion.

- If your primary focus is cost-efficiency: Liquid phase sintering can be an effective strategy to reduce energy consumption by lowering the required process temperature.

Ultimately, mastering the sintering process is about precisely controlling heat to transform a loose powder into a dense, solid, and functional component.

Summary Table:

| Factor | Influence on Sintering Temperature |

|---|---|

| Material | Metals (e.g., steel): ~1120-1300°C; Ceramics (e.g., alumina): >1600°C; Plastics (e.g., PTFE): ~360-380°C |

| Target Density | Higher density requires higher temperature (e.g., full density achieved at 630°C for some materials). |

| Additives | Liquid phase sintering with additives allows for lower temperatures. |

| Time vs. Temperature | Lower temperature can be used with longer hold times to achieve similar results and control grain growth. |

Achieve precise control over your sintering process with KINTEK.

Whether you are working with metals, ceramics, or specialized materials, selecting and maintaining the correct sintering temperature is critical for achieving the desired density, strength, and dimensional accuracy in your components. KINTEK specializes in high-performance lab furnaces and thermal processing equipment that deliver the precise temperature control and uniform heating your sintering applications demand.

Our experts can help you select the right equipment to optimize your thermal treatment for maximum efficiency and product quality. Contact our team today to discuss your specific sintering requirements and discover how KINTEK's solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab