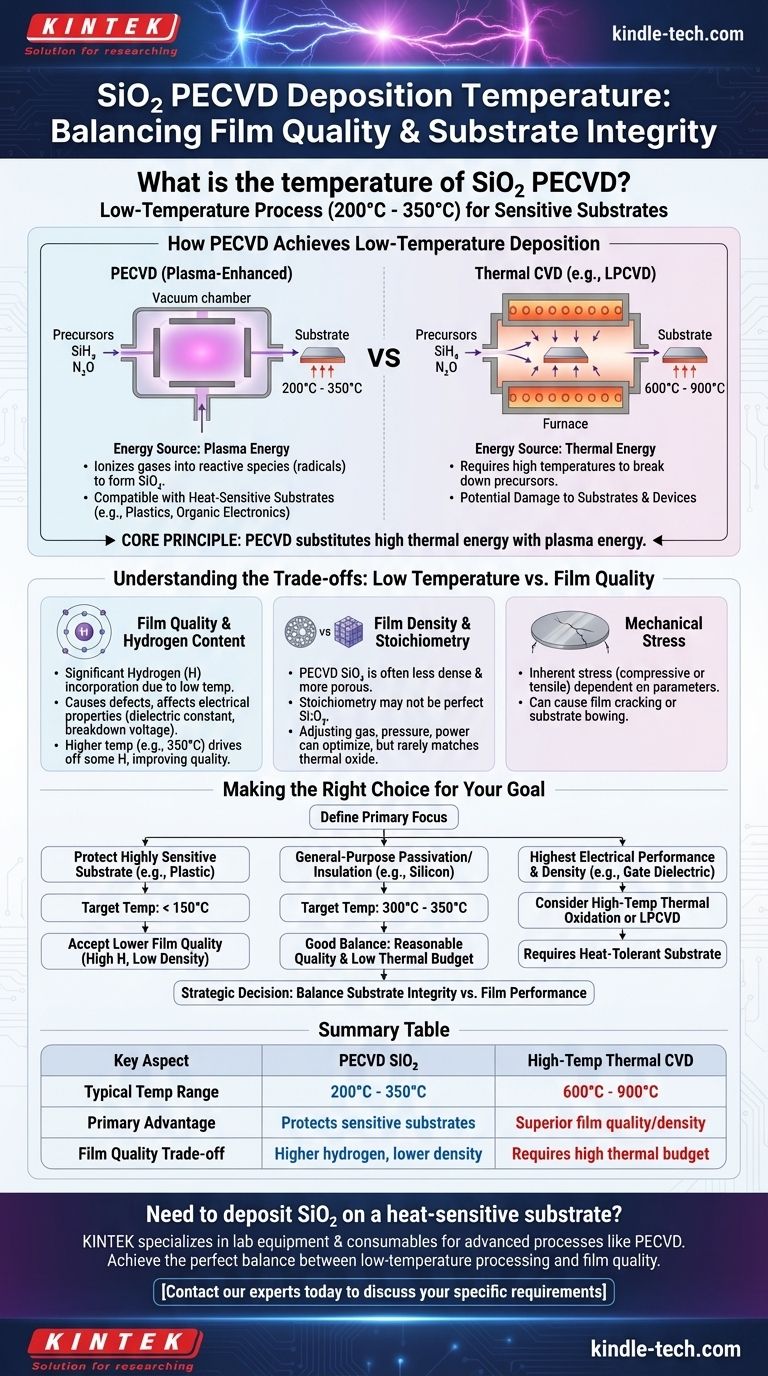

The deposition temperature for silicon dioxide (SiO₂) using Plasma-Enhanced Chemical Vapor Deposition (PECVD) is typically in the low-temperature range of 200°C to 350°C. While processes can run near room temperature, this higher range is more common for producing functional films, striking a balance between deposition rate and film quality. The key advantage of PECVD is its ability to operate at these low temperatures, making it compatible with substrates that cannot withstand high thermal loads.

The core principle to understand is that PECVD substitutes high thermal energy with plasma energy to drive the chemical reaction. This low-temperature capability is its defining feature, but it introduces critical trade-offs in film quality and composition compared to high-temperature methods.

How PECVD Achieves Low-Temperature Deposition

The fundamental difference between PECVD and conventional thermal Chemical Vapor Deposition (CVD) is its energy source.

The Role of Plasma

In PECVD, an electrical field is used to ionize precursor gases (like silane and nitrous oxide) into a state of matter called plasma.

This plasma is a highly energetic environment containing ions, electrons, and reactive neutral species called radicals. These radicals are chemically reactive enough to form SiO₂ on the substrate surface without requiring high temperatures.

A Contrast with Thermal Methods

Traditional thermal CVD processes, such as Low-Pressure CVD (LPCVD), rely solely on thermal energy to break down precursor gases.

This requires much higher temperatures, often in the range of 600°C to 900°C, to provide sufficient energy for the chemical reactions to occur. Such high temperatures would damage or destroy many materials, such as plastics, certain semiconductors, or devices with pre-existing metal layers.

Understanding the Trade-offs

The low-temperature nature of PECVD is a significant advantage, but it is not without compromises. The quality of the resulting SiO₂ film is directly linked to the deposition conditions.

Film Quality and Hydrogen Content

Because PECVD uses hydrogen-containing precursors (e.g., silane, SiH₄) at low temperatures, a significant amount of hydrogen can be incorporated into the deposited SiO₂ film.

This bonded hydrogen can create defects and affect the film's electrical properties, such as its dielectric constant and breakdown voltage. Higher deposition temperatures (e.g., 350°C) help drive off some of this hydrogen, generally improving film quality.

Film Density and Stoichiometry

PECVD SiO₂ is often less dense and more porous than oxide grown at high temperatures (thermal oxide).

The stoichiometry may also not be a perfect Si:O₂ ratio. Adjusting gas flows, pressure, and plasma power can help optimize density, but it rarely matches the quality of a thermally grown oxide.

Mechanical Stress

Films deposited via PECVD have an inherent mechanical stress (either compressive or tensile) that is highly dependent on the deposition parameters.

While this can sometimes be tuned for specific applications, unmanaged stress can cause film cracking or substrate bowing, especially on thin wafers.

Making the Right Choice for Your Goal

The ideal deposition temperature is not a single number; it depends entirely on your substrate limitations and film quality requirements.

- If your primary focus is protecting a highly sensitive substrate (e.g., plastic or organic electronics): You will need to operate at the lowest possible temperature, often below 150°C, and accept the resulting lower film quality.

- If your primary focus is general-purpose passivation or insulation on a robust substrate (e.g., silicon): A temperature between 300°C and 350°C is a common choice, as it offers a good balance of reasonable film quality and a low thermal budget.

- If your primary focus is achieving the highest electrical performance and density (e.g., a gate dielectric): PECVD may not be the right process; high-temperature thermal oxidation or LPCVD should be considered if the substrate can tolerate the heat.

Ultimately, choosing a PECVD temperature is a strategic decision that balances the need for substrate integrity against the demand for film performance.

Summary Table:

| Key Aspect | PECVD SiO2 | High-Temp Thermal CVD |

|---|---|---|

| Typical Temperature Range | 200°C - 350°C | 600°C - 900°C |

| Primary Advantage | Protects sensitive substrates | Superior film quality/density |

| Film Quality Trade-off | Higher hydrogen content, lower density | Requires high thermal budget |

Need to deposit SiO2 on a heat-sensitive substrate?

KINTEK specializes in lab equipment and consumables for advanced processes like PECVD. Our expertise can help you select the right system to achieve the perfect balance between low-temperature processing and the film quality your application demands.

Contact our experts today to discuss your specific substrate and film requirements.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained