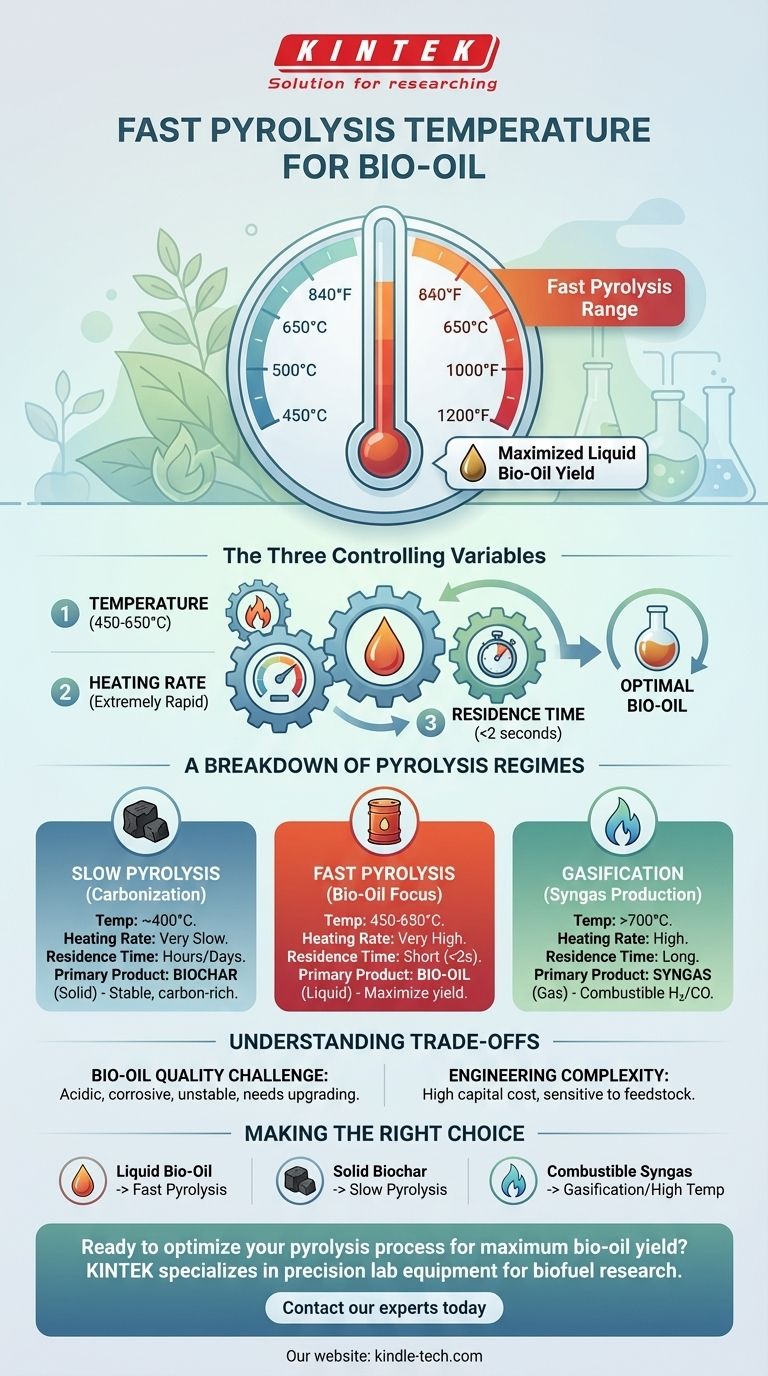

In the context of biofuel production, fast pyrolysis is typically conducted in a temperature range of 450°C to 650°C (840°F to 1200°F). This specific temperature window is part of a larger set of conditions, including extremely rapid heating, designed to maximize the yield of liquid bio-oil from biomass feedstock.

While temperature is the most cited variable, the true outcome of pyrolysis is determined by a carefully controlled interplay between three factors: temperature, heating rate, and vapor residence time. Mastering this balance is the key to steering the process toward your desired product—whether it's liquid fuel, solid char, or combustible gas.

The Role of Process Conditions in Pyrolysis

To understand why the fast pyrolysis temperature range is so specific, we must first understand the fundamental principles at play.

What is Pyrolysis?

Pyrolysis is the thermal decomposition of organic material at elevated temperatures in the absence of oxygen. Without oxygen, the material does not combust; instead, its complex chemical structures break down into simpler, smaller molecules.

The final products of this process fall into three categories: a liquid (bio-oil), a solid (biochar), and non-condensable gases (syngas).

The Three Controlling Variables

The ratio of these three products is not random. It is dictated by three interconnected process variables:

- Temperature: Determines which chemical bonds break and the stability of the resulting products.

- Heating Rate: The speed at which the feedstock reaches the target temperature.

- Residence Time: How long the hot vapors remain in the reactor before being cooled and collected.

A Breakdown of Pyrolysis Regimes

Different combinations of these variables define the specific type of pyrolysis and its primary output. The general temperature range for all pyrolysis types spans from 400°C to over 900°C.

Slow Pyrolysis (Carbonization)

Slow pyrolysis uses lower temperatures (around 400°C), very slow heating rates, and extremely long residence times (hours or even days).

These conditions favor the formation of a stable, carbon-rich solid. The primary goal of slow pyrolysis is to produce biochar.

Fast Pyrolysis

Fast pyrolysis occupies a middle-ground temperature range (450-650°C) but is defined by its extremely high heating rates and very short vapor residence times (typically less than 2 seconds).

The goal is to rapidly break down the biomass and immediately remove the vapors before they can undergo further reactions. This process is optimized to maximize the yield of liquid bio-oil, often reaching 60-75% by weight.

Gasification

At the highest end of the spectrum (typically above 700°C), the process favors the breakdown of all components into the simplest gaseous molecules.

With long residence times and high temperatures, this process is optimized to produce a combustible syngas, a mixture primarily composed of hydrogen (H₂) and carbon monoxide (CO).

Understanding the Trade-offs

Choosing a pyrolysis regime involves significant engineering and economic trade-offs. Fast pyrolysis is a powerful tool for creating liquid fuels, but it comes with distinct challenges.

The Challenge of Bio-Oil Quality

The bio-oil produced through fast pyrolysis is not a drop-in replacement for crude oil. It is highly acidic, corrosive, thermally unstable, and contains a significant amount of water and oxygen.

This "pyrolysis oil" requires substantial and often costly upgrading (such as hydrotreating) before it can be used as a transportation fuel or blended with conventional petroleum products.

Engineering and Operational Complexity

Achieving the very high heating rates required for fast pyrolysis necessitates sophisticated and capital-intensive reactors, such as circulating fluidized bed or ablative reactors.

These systems are more complex to operate and maintain than the simple kilns used for slow pyrolysis. They are also highly sensitive to feedstock properties like particle size and moisture content, which must be carefully controlled.

Making the Right Choice for Your Goal

The optimal temperature and process conditions are entirely dependent on your desired end product.

- If your primary focus is maximizing liquid bio-oil: Implement fast pyrolysis conditions (450-650°C) with very high heating rates and short vapor residence times.

- If your primary focus is maximizing solid biochar for soil amendment or carbon sequestration: Opt for slow pyrolysis at lower temperatures (around 400°C) with very slow heating rates.

- If your primary focus is producing combustible syngas for power generation: Utilize very high-temperature pyrolysis or gasification (above 700°C) to ensure complete thermal cracking.

Ultimately, temperature is just one lever; mastering its relationship with heating rate and residence time is what unlocks the full potential of biomass conversion.

Summary Table:

| Pyrolysis Type | Typical Temperature Range | Primary Product | Key Characteristic |

|---|---|---|---|

| Slow Pyrolysis | ~400°C | Biochar (Solid) | Long residence time, slow heating |

| Fast Pyrolysis | 450-650°C | Bio-Oil (Liquid) | Very high heating rate, short vapor residence |

| Gasification | >700°C | Syngas (Gas) | High temperature, produces combustible gas |

Ready to optimize your pyrolysis process for maximum bio-oil yield? KINTEK specializes in precision lab equipment and reactors designed for advanced biofuel research. Whether you're developing fast pyrolysis parameters or scaling up your biomass conversion, our solutions deliver the precise temperature control and rapid heating rates you need.

Contact our experts today to discuss how KINTEK can enhance your laboratory's capabilities and accelerate your renewable energy projects.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- What is the burnout cycle on a furnace? Stop This Destructive Overheating Pattern Now

- Does casting change material properties? Understand the Microstructural Impact on Performance

- What is the theory of muffle furnace? Achieve Pure, Controlled High-Temperature Processing

- What is the difference between sintering and firing? A Guide to Thermal Process Terminology