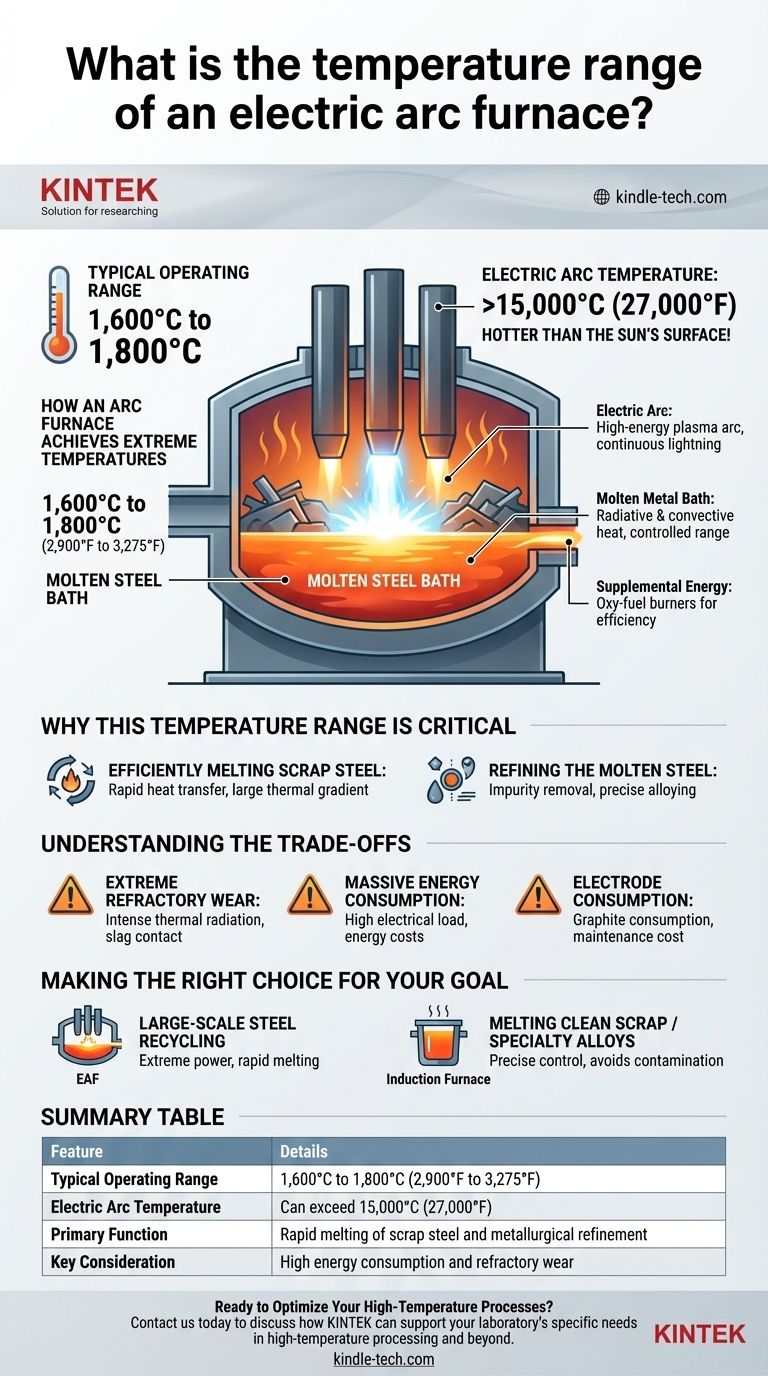

In practice, an electric arc furnace (EAF) operates with a molten steel bath temperature typically ranging from 1,600°C to 1,800°C (2,900°F to 3,275°F). While the electric arc itself can reach temperatures many times higher, this operational range is the critical target for melting scrap steel and performing metallurgical refinement.

The immense temperature of an electric arc is not just a number; it is the core enabling feature of the furnace. This thermal power is what allows an EAF to rapidly melt massive volumes of solid scrap steel, a task that demands an incredible concentration of energy.

How an Arc Furnace Achieves Extreme Temperatures

An EAF generates heat through a fundamentally different mechanism than a conventional combustion or induction furnace. The process relies on creating a controlled, high-energy plasma arc.

The Electric Arc Itself

The primary heat source is a sustained electric arc, which is essentially a continuous bolt of lightning. This arc forms between large graphite electrodes and the metallic charge (the scrap steel) inside the furnace.

This process ionizes the surrounding gases, creating a plasma column where temperatures can locally and momentarily exceed 15,000°C (27,000°F). This is far hotter than the surface of the sun.

The Molten Metal Bath

The intense radiative and convective heat from the arc is transferred directly to the scrap metal, causing it to melt. The goal is not to heat the entire furnace to 15,000°C, but to use the arc's concentrated energy to create and maintain a pool of molten steel.

The temperature of this molten bath is carefully controlled to be just above steel's melting point (around 1,500°C) to ensure it is fully liquid and to facilitate refining processes. The typical operating target is 1,600°C to 1,800°C.

Supplemental Energy Sources

To improve efficiency and speed up melting, most modern EAFs also use chemical energy. Oxy-fuel burners are used to inject oxygen and natural gas, creating secondary heat sources that help melt scrap in areas the arc cannot easily reach.

Why This Temperature Range Is Critical

The specific temperature range of an EAF is dictated by the physics of steelmaking. Operating within this window is essential for both melting and quality control.

Efficiently Melting Scrap Steel

The primary function of an EAF is recycling. It must be able to melt tons of cold, solid scrap steel quickly and reliably. Operating at temperatures significantly above steel's melting point creates a large thermal gradient, driving rapid heat transfer and melting.

Refining the Molten Steel

Once the steel is molten, the high temperature facilitates crucial metallurgical reactions. It allows for the removal of impurities like phosphorus and sulfur and enables the precise addition of alloying elements (such as chromium, nickel, or manganese) to produce specific grades of steel.

Understanding the Trade-offs

Achieving and containing these temperatures presents significant engineering and operational challenges.

Extreme Refractory Wear

The vessel of an EAF is lined with specialized, heat-resistant bricks known as refractories. The intense thermal radiation from the arc and contact with molten slag and steel causes this lining to degrade over time. Managing refractory wear is a primary maintenance concern and a major operational cost.

Massive Energy Consumption

Maintaining an electric arc of this magnitude requires an enormous amount of electrical power. An EAF is often the single largest electrical load in its region and places immense demands on the power grid. Energy costs are a dominant factor in the furnace's economic viability.

Electrode Consumption

The graphite electrodes are not permanent. The tip of the electrode is slowly consumed by the extreme heat and electrical current of the arc. Replacing these large, expensive electrodes is another significant and unavoidable operational cost.

Making the Right Choice for Your Goal

The temperature profile of a furnace determines its ideal application. Understanding this helps clarify why different technologies exist for different metallurgical tasks.

- If your primary focus is large-scale steel recycling: The EAF is the superior choice because its extreme arc temperature provides the raw power needed to rapidly melt tons of unprepared scrap metal.

- If your primary focus is melting clean scrap or producing high-purity specialty alloys: An induction furnace may be more suitable. While it also reaches high temperatures (up to 1,800°C or more), its inductive heating method offers more precise control and avoids carbon contamination from graphite electrodes.

Ultimately, the temperature capability of any furnace is a direct reflection of the specific metallurgical job it was designed to perform.

Summary Table:

| Feature | Details |

|---|---|

| Typical Operating Range | 1,600°C to 1,800°C (2,900°F to 3,275°F) |

| Electric Arc Temperature | Can exceed 15,000°C (27,000°F) |

| Primary Function | Rapid melting of scrap steel and metallurgical refinement |

| Key Consideration | High energy consumption and refractory wear |

Ready to Optimize Your High-Temperature Processes?

Choosing the right equipment is critical for efficient and cost-effective metal production. KINTEK specializes in providing robust lab equipment and consumables tailored to demanding industrial and research applications. Whether you're exploring furnace technologies or need reliable supplies for your laboratory, our expertise can help you achieve superior results.

Contact us today to discuss how KINTEK can support your laboratory's specific needs in high-temperature processing and beyond.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results