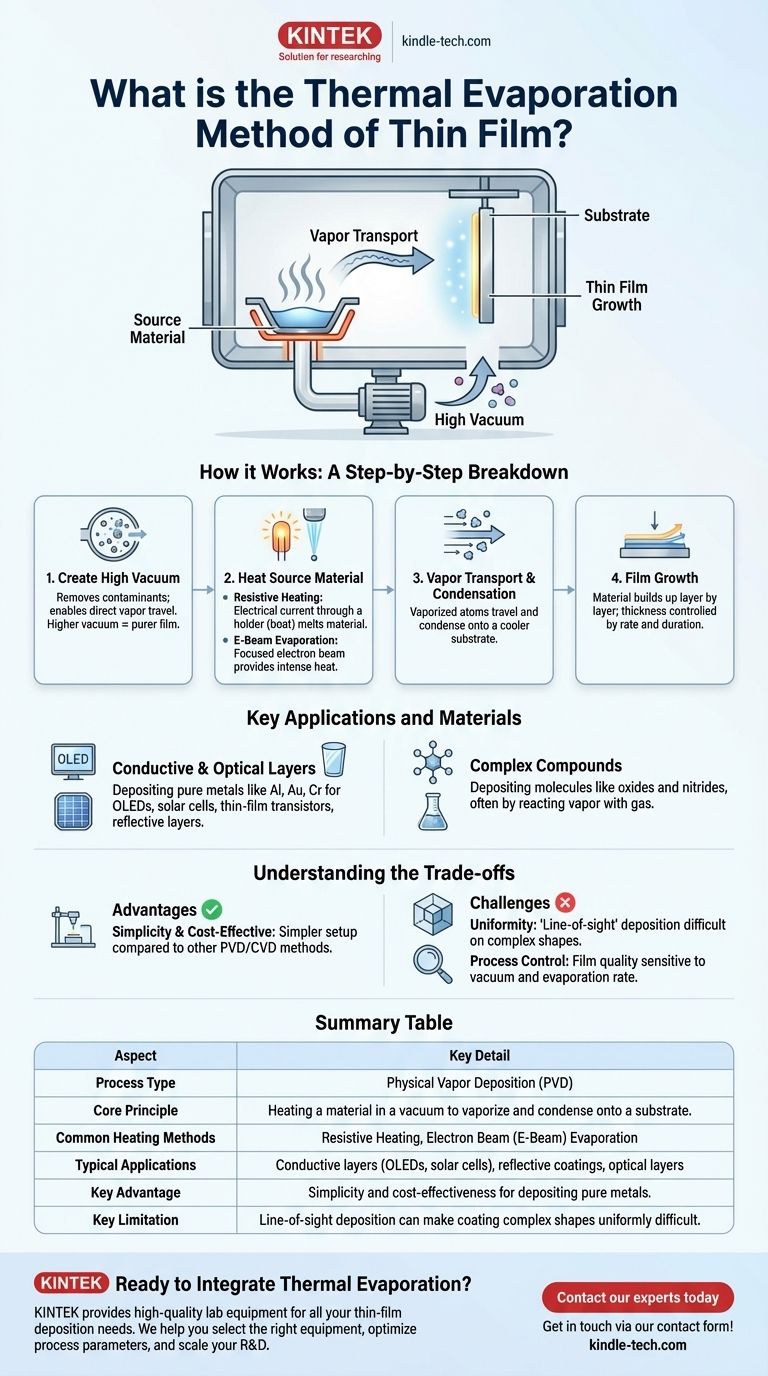

At its core, thermal evaporation is a physical vapor deposition (PVD) technique used to create ultra-thin films. The process works by heating a source material in a high-vacuum chamber until it vaporizes. These vaporized atoms or molecules then travel through the vacuum and condense onto a cooler target object, known as a substrate, forming a solid, thin film.

Thermal evaporation is a foundational and widely used method for depositing thin films due to its relative simplicity. However, the quality and purity of the resulting film are highly dependent on precise control over the vacuum environment and the rate of material evaporation.

How Thermal Evaporation Works: A Step-by-Step Breakdown

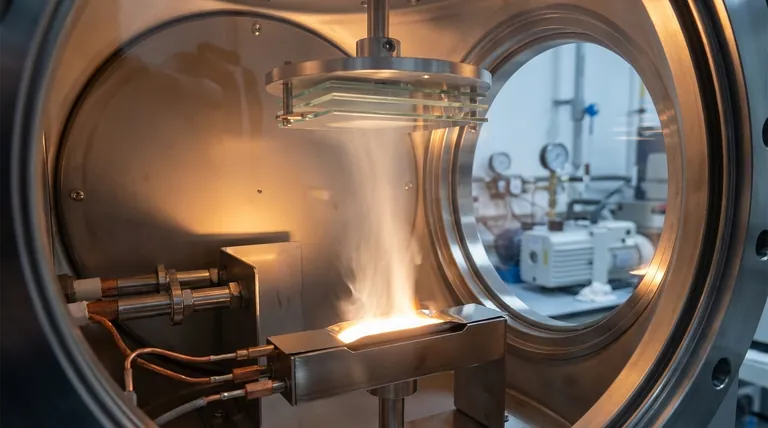

The entire process occurs within a sealed vacuum chamber and relies on a few fundamental physical principles.

### The Critical Role of the Vacuum

The process begins by creating a high vacuum inside the chamber. This serves two purposes: it removes air and other gas molecules that could contaminate the film, and it allows the vaporized source material to travel directly to the substrate without colliding with other particles. A higher degree of vacuum ensures a purer film.

### Heating the Source Material

To turn the solid source material into a vapor, intense heat is applied. This is typically achieved in one of two ways:

- Resistive Heating: The source material is placed in a holder, often called a "boat" or "basket," made from a high-temperature material like tungsten. A strong electrical current is passed through this holder, causing it to heat up and, in turn, melt and evaporate the source material.

- Electron Beam (E-Beam) Evaporation: A high-energy beam of electrons is focused directly onto the source material. The intense energy from the beam heats the material to its evaporation point. This method is often used for materials with very high melting points.

### Vapor Transport and Condensation

Once vaporized, the atoms or molecules travel in a straight line from the source to everything inside the chamber. When this vapor stream hits the cooler substrate, it rapidly cools and condenses, transitioning back into a solid state.

### Film Growth

As more material is evaporated, it continuously condenses on the substrate, building up layer by layer to form a solid thin film. The final thickness is controlled by the rate of evaporation and the duration of the process.

Key Applications and Materials

Thermal evaporation is valued for its versatility in depositing a wide range of materials for various high-tech applications.

### Creating Conductive and Optical Layers

This method is a go-to for depositing pure metals like aluminum, gold, and chromium. These layers often serve as electrically conductive contacts in devices like OLED displays, solar cells, and thin-film transistors. It is also used for creating reflective layers on glass and other surfaces.

### Depositing Complex Compounds

While excellent for pure elements, thermal evaporation can also be used to deposit molecules like oxides and nitrides. This is achieved by evaporating the source material and allowing it to react with a controlled amount of gas (like oxygen or nitrogen) inside the chamber, or by directly evaporating the compound itself.

Understanding the Trade-offs

No single method is perfect for every scenario. Understanding the advantages and limitations of thermal evaporation is key to using it effectively.

### The Advantage of Simplicity

Compared to other PVD or Chemical Vapor Deposition (CVD) methods, thermal evaporation is often simpler in its setup and operation. This can make it a more cost-effective solution for many applications.

### The Challenge of Uniformity

Because the vapor travels in a straight "line-of-sight" from the source, coating complex, three-dimensional shapes uniformly can be difficult. Areas not directly in the path of the vapor will receive little to no coating. This can be partially mitigated by rotating the substrate during deposition.

### Sensitivity to Process Control

The final film quality is highly sensitive to the process parameters. A low-quality vacuum will introduce impurities. An inconsistent evaporation rate can lead to a poorly structured film. Likewise, a rough or contaminated substrate surface will result in non-uniform deposition.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on your project's requirements for material, quality, and cost.

- If your primary focus is cost-effective deposition of simple metals: Resistive thermal evaporation is an excellent, straightforward choice for applications like basic electrodes or reflective coatings.

- If you need to deposit high-melting-point materials or require higher deposition rates: E-beam evaporation provides the necessary energy and control that standard resistive heating may not.

- If your goal is maximum film purity and conformity on complex shapes: You may need to investigate more advanced techniques like sputtering or Atomic Layer Deposition (ALD), which offer superior control.

By understanding these fundamental principles, you can effectively leverage thermal evaporation to achieve the precise film characteristics your project requires.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Heating a material in a vacuum to vaporize and condense it onto a substrate. |

| Common Heating Methods | Resistive Heating, Electron Beam (E-Beam) Evaporation |

| Typical Applications | Conductive layers (OLEDs, solar cells), reflective coatings, optical layers |

| Key Advantage | Simplicity and cost-effectiveness for depositing pure metals. |

| Key Limitation | Line-of-sight deposition can make coating complex shapes uniformly difficult. |

Ready to integrate thermal evaporation into your lab workflow?

KINTEK specializes in providing high-quality lab equipment and consumables for all your thin-film deposition needs. Whether you are developing new electronic devices, solar cells, or optical coatings, our expertise and reliable products ensure you achieve precise and consistent results.

We help you:

- Select the right equipment for your specific materials and application goals.

- Optimize your process parameters for superior film quality and purity.

- Scale your R&D with dependable and efficient laboratory solutions.

Contact our experts today to discuss how we can support your laboratory's innovation. Get in touch via our contact form!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is vacuum deposition process? Achieve High-Performance Coatings with Precision

- What is thermal evaporation method? A Simple Guide to Thin-Film Deposition

- What is the thermal evaporation technique in a vacuum? A Guide to High-Purity Thin-Film Deposition

- What is the electron beam method? A Guide to Precision Coating, Cutting & Sterilization

- What is thermal evaporation of thin film? A Guide to High-Purity PVD Coating

- What are the problems with physical Vapour deposition? High Cost, Slow Speed, and Line-of-Sight Limitations

- What is the vacuum level of the e-beam evaporator? Achieve Pure, High-Quality Thin Films