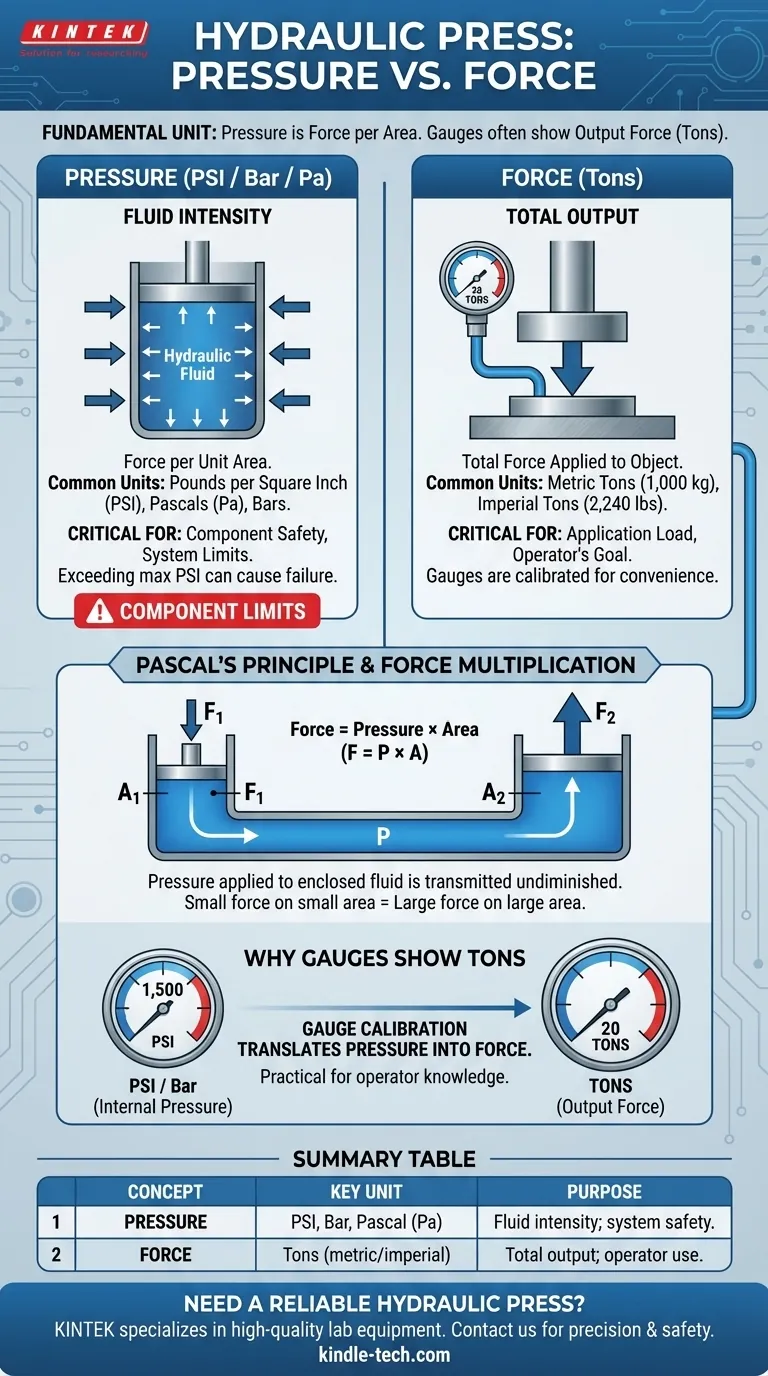

The fundamental unit of pressure in any hydraulic system is expressed as force per unit of area. The most common units are Pounds per Square Inch (PSI) in the imperial system and Pascals (Pa) or bars in the metric system. While a press gauge may be calibrated to show tons, this is a measure of the output force, not the internal fluid pressure.

The core distinction to understand is that a hydraulic press operates on fluid pressure (force per area), but its performance is often measured by the total output force (tons) it can generate. Gauges are frequently labeled in tons for operator convenience, translating the internal pressure into the resulting applied force.

The Physics: Pressure vs. Force

The ability of a hydraulic press to generate immense force from a small input is governed by a core principle of fluid dynamics. Understanding the difference between the system's pressure and its output force is critical.

The True Unit: Pressure

Pressure is the amount of force exerted over a specific area. Think of it as the intensity of the force within the hydraulic fluid.

The standard scientific unit is the Pascal (Pa), which is one Newton of force per square meter. In industrial applications, you will more commonly encounter PSI (Pounds per Square Inch) or bars (1 bar is roughly equal to atmospheric pressure at sea level, or 100,000 Pa).

The Measured Result: Force

While pressure does the work, the operator's goal is to apply a specific force to an object. This is why many gauges are simplified to show the end result.

The units you see on the gauge—metric tons (1,000 kg) or imperial tons (2,240 lbs)—are direct measurements of the total output force the press is exerting at that moment.

How Pressure Creates Force: Pascal's Principle

The magic of a hydraulic system comes from Pascal's Principle, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

The Force Multiplication Formula

The relationship is defined by the formula: Force = Pressure × Area.

A small force applied to a small piston creates pressure in the fluid. This same pressure then acts on a much larger piston, and because its area is larger, the resulting output force is magnified significantly.

Why Gauges Show Tons

It is far more practical for an operator to know they are applying "20 tons of force" than to calculate that force from a reading of "1,500 PSI" acting on a piston with a 26-square-inch area.

The gauge does the math for you. It measures the internal fluid pressure but the dial is calibrated to display the corresponding output force in tons.

Common Pitfalls to Avoid

Confusing the concepts of pressure and force can lead to operational errors and safety risks. Understanding the distinction is not just academic; it's essential for correct and safe operation.

Overlooking Component Limits

Hydraulic components like hoses, seals, and cylinders are rated for a maximum pressure (e.g., 3,000 PSI). Exceeding this pressure can cause a catastrophic failure, even if the output force seems within a normal range for a different press.

Assuming Force is Constant

If you were to switch out the main cylinder on a press for one with a larger diameter (a larger area), the same internal fluid pressure would now produce a much greater output force. The "tons" reading on the old gauge would become inaccurate.

Making the Right Choice for Your Goal

Your interpretation of the system depends entirely on your objective.

- If your primary focus is applying a specific load: Trust the force reading on your gauge (tons). It is designed to tell you the direct output you are applying to your workpiece.

- If your primary focus is maintenance or system design: You must work with the pressure rating (PSI or bar) of the individual components to ensure the system is operating safely within its design limits.

Ultimately, mastering a hydraulic press means understanding that pressure is the cause and force is the effect.

Summary Table:

| Concept | Key Unit | Purpose |

|---|---|---|

| Pressure | PSI, Bar, Pascal (Pa) | Measures fluid intensity; critical for system safety and component limits. |

| Force | Tons (metric/imperial) | Measures total output on the workpiece; what the operator directly uses. |

Need a reliable hydraulic press for your lab or production line? KINTEK specializes in high-quality lab equipment, including hydraulic presses designed for precision and safety. Our experts can help you select the right press with the correct pressure and force ratings for your specific application. Contact us today to ensure your operations are both efficient and safe!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why is a pre-pressing step using a laboratory hydraulic press necessary? Key to Stable Particleboard Mats

- How is a laboratory hydraulic press utilized in the preparation of samples during the solvent precipitation recovery of polyamides? Achieve Precise Densification

- What is a pressed pellet for XRF analysis? A Guide to Accurate Sample Preparation

- What is the advantage of hydraulic press over mechanical press? Superior Control, Lower Cost & Built-in Protection

- Is compression molding a fast process? A Guide to Faster Time-to-Market for Low-Volume Production

- How do you maintain a press machine? A Proactive Guide to Maximize Uptime and Safety

- What is the pressure range for a filter press? Achieve Optimal Dewatering & Cake Dryness

- What is the use of C type power press? Versatile Metal Forming for Punching, Stamping, and Bending