At its core, a hand press machine is a tool for precision force application. It uses mechanical leverage—typically a lever combined with a rack-and-pinion gear system—to allow an operator to press, insert, remove, or stamp components with significant, controlled force. This makes it indispensable for tasks requiring more power than a simple hammer but more tactile feedback and control than a large, powered press.

The true value of a hand press isn't its raw power, but its control. It excels in workshop and small-scale production environments where an operator's "feel" for the right amount of pressure is critical for assembling or modifying parts without causing damage.

How a Hand Press Achieves Its Force

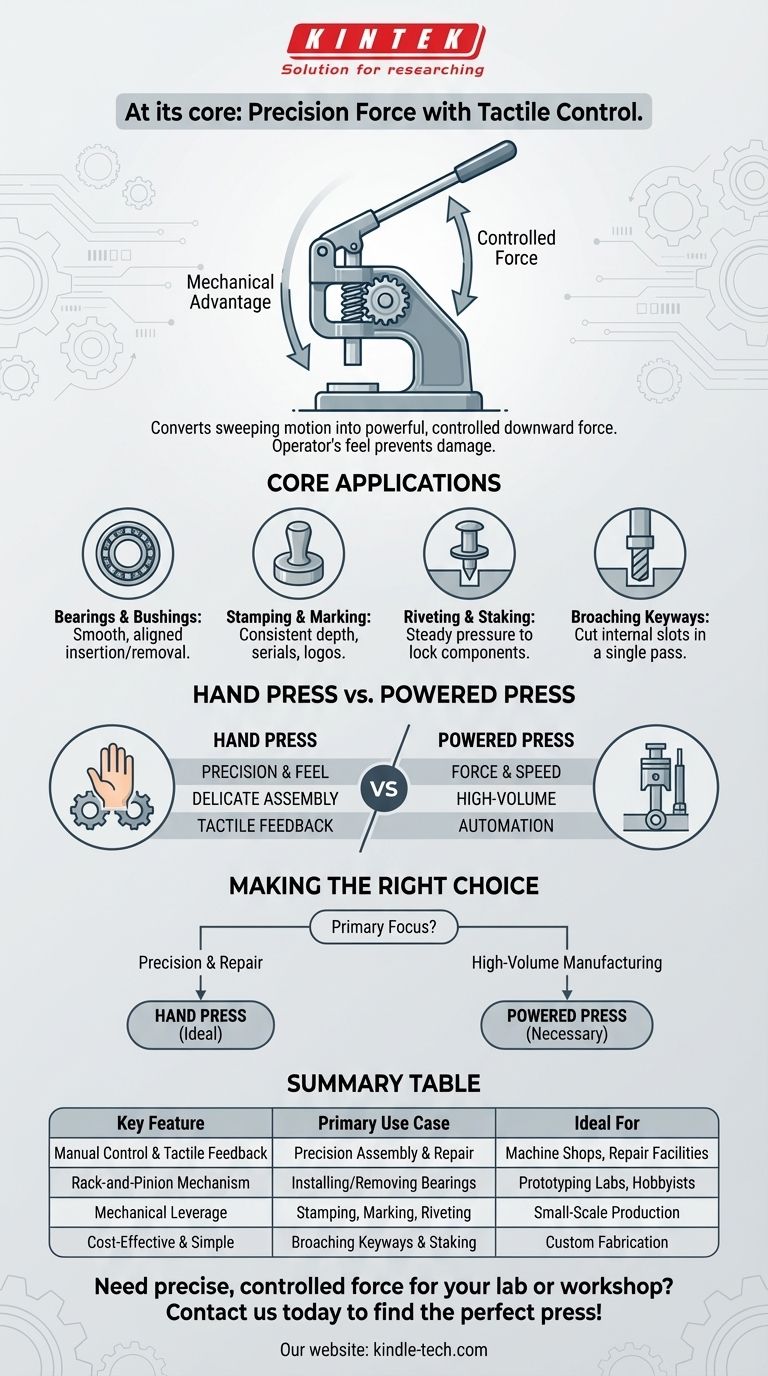

A hand press, often called an arbor press, operates on the fundamental principle of mechanical advantage. By converting the long, sweeping motion of a handle into the short, powerful downward motion of a ram, it multiplies the force exerted by the user.

The Role of the Lever and Ram

The long handle acts as a lever, making it easier for the operator to initiate the force. This force is then transferred to the ram, which is the solid steel cylinder that moves vertically to perform the work.

The Rack-and-Pinion System

The most common mechanism inside a hand press is a rack-and-pinion. The lever is attached to a pinion (a small circular gear), and its teeth engage with a rack (a flat, toothed bar) on the side of the ram. As the lever is pulled, the pinion rotates, driving the ram straight down with amplified force.

Why Manual Control is the Key Advantage

Unlike a powered press, the operator can feel the resistance as a part is being seated or a pin is being pushed. This tactile feedback is crucial for preventing over-pressing, which can crack a housing or damage a delicate bearing.

Core Applications and Uses

The versatility of a hand press makes it a staple in machine shops, repair facilities, and prototyping labs. Its applications all revolve around the controlled application of linear force.

Installing and Removing Bearings & Bushings

This is the most common use for a hand press. It allows for the smooth and perfectly aligned insertion of press-fit bearings into a housing without damaging either component. It is equally effective for pushing old bearings out.

Stamping and Marking

When fitted with a die stamp, a hand press can be used to permanently mark parts with serial numbers, logos, or other identifiers. It provides a consistent depth and clarity that is difficult to achieve with a hammer and punch.

Riveting and Staking

The press provides the steady, controlled pressure needed to set rivets or to stake material, which involves deforming a metal post or edge to lock another component in place.

Broaching Keyways

With a special cutting tool called a broach, a hand press can be used to cut internal keyways into gears or pulleys. The press pushes the multi-toothed broach through the hole, cutting the slot in a single pass.

Understanding the Trade-offs: Hand Press vs. Powered Presses

Choosing the right press means understanding its limitations compared to hydraulic or pneumatic alternatives.

Force Limitation

The force of a hand press is limited by the physical strength of the operator and the gear ratio of the press. For jobs requiring many tons of force, such as large-scale forming or crushing, a hydraulic press is necessary.

Speed and Repetition

A hand press is a manual, single-action tool. For high-volume, repetitive production work, the speed and automation of a pneumatic (air-powered) or hydraulic press are far superior.

Precision and Feel

This is where the hand press shines. Powered presses can easily apply too much force too quickly, leading to damaged parts. The manual control of a hand press is unmatched for delicate assembly operations.

Cost and Complexity

Hand presses are mechanically simple, relatively inexpensive, and easy to maintain. Powered presses are more complex, require more significant investment, and have higher operational costs.

Making the Right Choice for Your Goal

To determine if a hand press is the correct tool, consider the primary requirement of your task.

- If your primary focus is precision assembly and repair: A hand press is ideal for its tactile feedback, preventing damage when seating bearings, pins, or other delicate components.

- If your primary focus is high-volume manufacturing: A hydraulic or pneumatic press is the necessary choice for its speed, consistency, and immense power.

- If your primary focus is custom fabrication or hobby work: The versatility, low cost, and small footprint of a hand press make it an essential and highly capable workshop tool.

Ultimately, a hand press empowers the user with controlled mechanical advantage for tasks where feel is just as important as force.

Summary Table:

| Key Feature | Primary Use Case | Ideal For |

|---|---|---|

| Manual Control & Tactile Feedback | Precision Assembly & Repair | Machine Shops, Repair Facilities |

| Rack-and-Pinion Mechanism | Installing/Removing Bearings & Bushings | Prototyping Labs, Hobbyists |

| Mechanical Leverage | Stamping, Marking, & Riveting | Small-Scale Production |

| Cost-Effective & Simple Operation | Broaching Keyways & Staking | Custom Fabrication |

Need precise, controlled force for your lab or workshop? KINTEK specializes in lab equipment and consumables, including robust hand press machines perfect for delicate assembly, bearing installation, and marking tasks. Our tools provide the tactile feedback and mechanical advantage your projects demand. Contact us today to find the perfect press for your laboratory needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What technical value does a four-column hydraulic press provide? Optimize Your Composite Powder Fabrication Today

- What is the function of a laboratory hydraulic press in PHA film production? Perfecting Bio-Packaging Standards

- What is the role of laboratory hydraulic presses or CIP in LFP solid-state battery assembly? Expert Insights

- What is the mechanism by which a laboratory hydraulic press facilitates the sintering of TiB2-SiC? Optimize Density

- Why is a high-pressure hydraulic press used for solid-state batteries? Achieve Optimal Li-Anode & Sulfide Integration

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- Press forging vs. hammer forging: Which is right for your metal forming needs?

- What is the purpose of using a pre-forming machine for Ni-Co-Al alloy powders? Optimize Your Hot Pressing Workflow