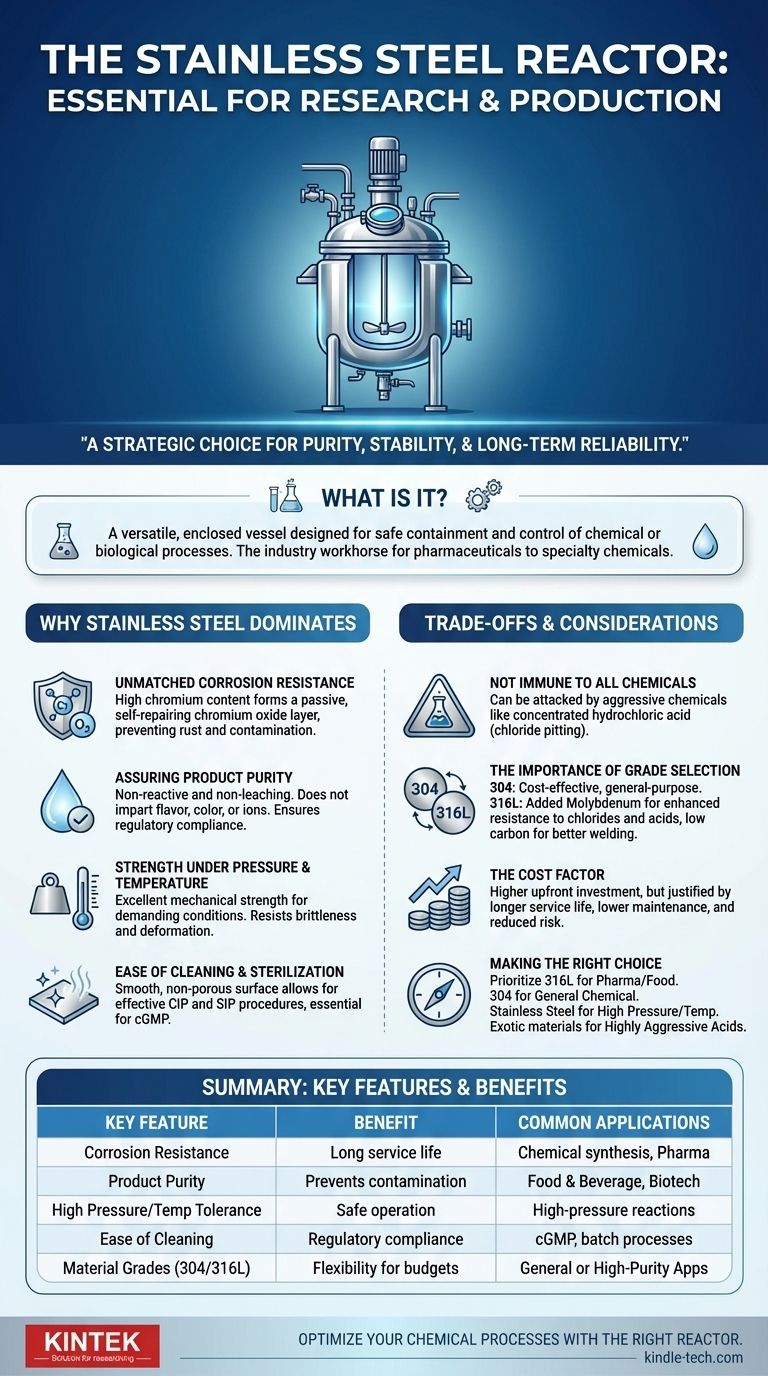

In short, a stainless steel reactor is a versatile, enclosed vessel designed to safely contain and control chemical or biological processes. It serves as the workhorse for industries ranging from pharmaceuticals to specialty chemicals, providing a sterile, corrosion-resistant environment for reactions, mixing, crystallization, and fermentation.

The decision to use a stainless steel reactor goes beyond simple containment. It is a strategic choice to ensure product purity, process stability, and long-term operational reliability in chemically aggressive and high-purity environments.

Why Stainless Steel is the Dominant Material

The selection of a reactor's material is one of the most critical decisions in process engineering. Stainless steel has become the industry standard for a set of fundamental reasons that directly impact safety, quality, and cost.

Unmatched Corrosion Resistance

The defining feature of stainless steel is its ability to resist corrosion. This is due to a high chromium content, which forms a thin, passive, self-repairing layer of chromium oxide on the surface.

This passive layer acts as a barrier, protecting the underlying steel from interacting with the process fluids, preventing both rust and contamination.

Assuring Product Purity

In industries like pharmaceuticals, food and beverage, and fine chemicals, even trace amounts of contamination can ruin a batch. Stainless steel is prized for being non-reactive and non-leaching.

It does not impart any flavor, color, or metallic ions into the product, ensuring the final output meets stringent quality and regulatory standards.

Strength Under Pressure and Temperature

Chemical reactions often involve high pressures and extreme temperatures. Stainless steel possesses excellent mechanical strength and durability, allowing it to safely operate under these demanding conditions.

Unlike glass, it is not brittle, and unlike many plastics, it does not deform or degrade at elevated temperatures, providing a much wider and safer operating window.

Ease of Cleaning and Sterilization

The smooth, non-porous surface of polished stainless steel makes it exceptionally easy to clean and sterilize. This is not just a convenience; it is a regulatory requirement in many fields.

This cleanability prevents cross-contamination between batches and allows for effective Steam-In-Place (SIP) and Clean-In-Place (CIP) procedures, which are essential for cGMP (Current Good Manufacturing Practice) compliance.

Understanding the Trade-offs and Limitations

While highly effective, stainless steel is not a universal solution. An objective assessment requires understanding its limitations.

Not Immune to All Chemicals

Despite its excellent general resistance, stainless steel can be attacked by certain aggressive chemicals. High concentrations of chloride ions, such as those found in hydrochloric acid, can cause pitting corrosion.

It is crucial to verify material compatibility against all chemicals involved in your process, especially under high temperatures and pressures.

The Importance of Grade Selection

Not all stainless steel is the same. The two most common grades for reactors are 304 and 316L.

- Type 304 is a cost-effective, general-purpose stainless steel with good corrosion resistance. It is suitable for a wide range of applications.

- Type 316L contains molybdenum, which significantly enhances its resistance to chlorides and acids. The "L" signifies low carbon content, which improves its properties after welding. It is the preferred choice for pharmaceutical, biotech, and saltwater-related applications.

The Cost Factor

Stainless steel reactors are significantly more expensive upfront than those made from carbon steel or some polymers. However, this initial investment is often justified by a longer service life, lower maintenance costs, and reduced risk of batch failure.

Making the Right Choice for Your Process

Your application's specific demands should dictate your material choice. Use these points as a guide for your decision-making.

- If your primary focus is pharmaceuticals or food production: You must prioritize 316L stainless steel for its superior purity, cleanability, and enhanced corrosion resistance.

- If your primary focus is general chemical synthesis on a budget: 304 stainless steel may provide a cost-effective and reliable solution for processes without high chloride content.

- If your process involves high pressures or wide temperature swings: The mechanical strength and thermal stability of stainless steel make it a far safer choice than glass or plastic.

- If you are handling highly aggressive acids like hydrochloric: You may need to consider more exotic and expensive materials like Hastelloy or glass-lined steel reactors.

Selecting the right reactor material is a foundational decision that directly impacts your process efficiency, product quality, and operational safety.

Summary Table:

| Key Feature | Benefit | Common Applications |

|---|---|---|

| Corrosion Resistance | Resists rust and chemical attack, ensuring long service life | Chemical synthesis, pharmaceutical production |

| Product Purity | Non-reactive surface prevents contamination | Food & beverage, fine chemicals, biotech |

| High Pressure/Temperature Tolerance | Withstands demanding process conditions safely | High-pressure reactions, polymerization |

| Ease of Cleaning & Sterilization | Supports CIP/SIP for regulatory compliance | cGMP manufacturing, batch processes |

| Material Grade Options (304/316L) | Flexibility for different budgets and chemical compatibilities | General-purpose (304) or high-purity (316L) applications |

Optimize your chemical processes with the right reactor. KINTEK specializes in high-quality lab equipment and consumables, including stainless steel reactors tailored to your laboratory's specific needs. Whether you require the general-purpose reliability of 304 stainless or the high-purity performance of 316L for pharmaceutical applications, our experts can help you select the ideal solution for safety, efficiency, and compliance. Contact us today to discuss your reactor requirements and enhance your lab's capabilities!

Visual Guide

Related Products

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How do you control temperature in a reactor? Master Thermal Balance for Safe & Efficient Reactions

- What is the heat transfer in agitated vessels? Master Temperature Control for Your Process

- What is the function of a high-pressure hydrothermal reactor? Synthesize Advanced Hydroxyapatite for Waste Management

- What process benefits does a high-pressure hydrothermal autoclave provide when synthesizing graphene-metal oxide hybrid catalysts? Enhance Catalytic Efficiency

- What is the primary function of a high-pressure autoclave in simulating HTHA? Reliable Hydrogen Attack Material Testing

- Why is a controlled atmosphere reactor necessary for researching AAS corrosion? Isolate Chemical Mechanisms Precisely

- What is the primary function of a high-pressure stainless steel stirred autoclave? Enhancing Furfural Hydrogenation

- What role does a laboratory reaction vessel play in CoxAl3FeyOm±δ synthesis? Achieve Precision Precursor Formation