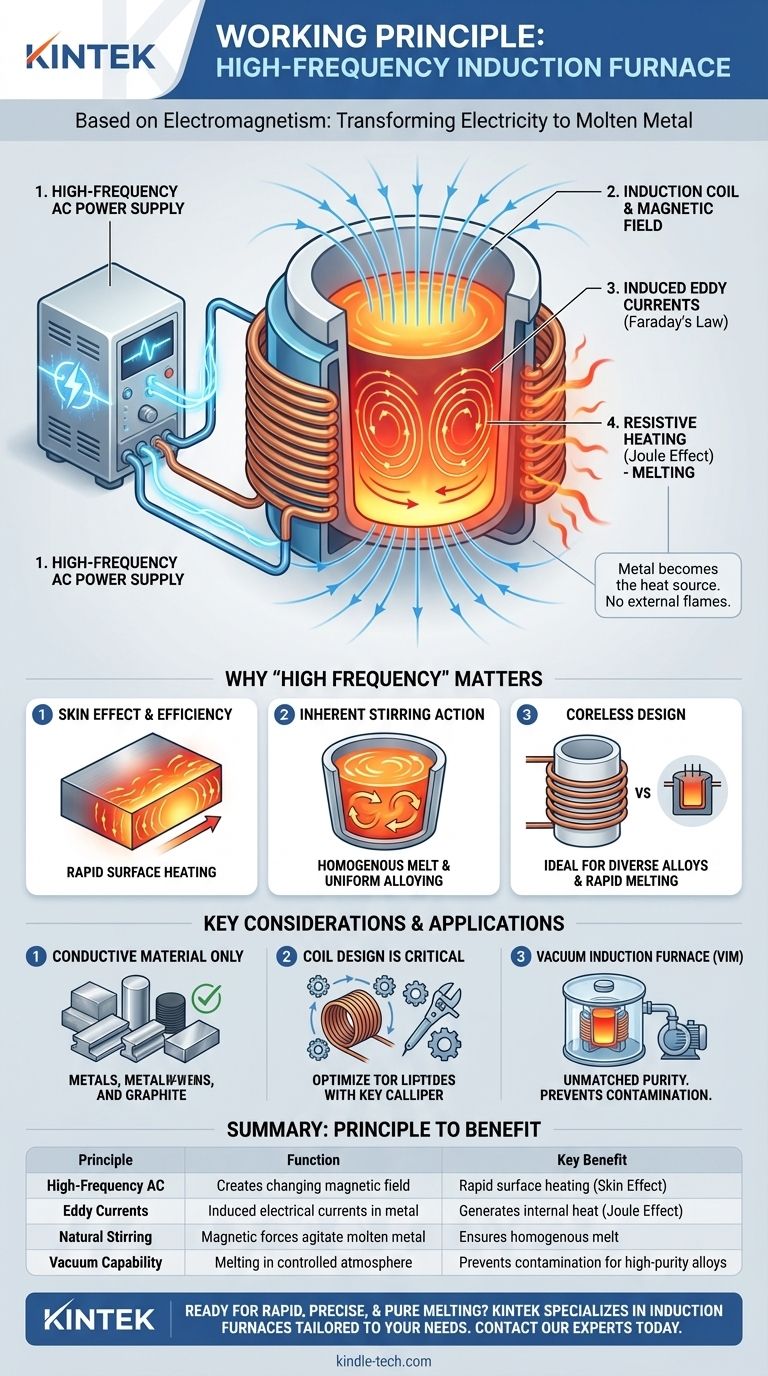

The working principle of a high-frequency induction furnace is based on the laws of electromagnetism. It uses a powerful, high-frequency alternating current flowing through a copper coil to generate a rapidly changing magnetic field around the metal to be melted. This magnetic field induces strong electrical currents, known as eddy currents, directly within the metal charge itself. The metal's inherent electrical resistance opposes these currents, generating intense, precise heat that causes the metal to melt from the inside out.

An induction furnace does not heat metal using external flames or heating elements. Instead, it uses electromagnetic principles to turn the piece of metal itself into the source of heat, enabling rapid, clean, and highly controlled melting.

The Core Mechanism: From Electricity to Molten Metal

Understanding the induction furnace requires breaking the process down into a sequence of physical principles. Each step logically follows the last, transforming electrical energy into thermal energy with remarkable efficiency.

Step 1: The High-Frequency Power Supply

The process begins with a specialized power unit that converts standard mains electricity into a high-frequency alternating current (AC). This is the engine that drives the entire system.

Step 2: The Induction Coil and Magnetic Field

This high-frequency AC is sent through a hollow, water-cooled copper coil. As the current rapidly alternates its direction, it generates a powerful and fluctuating magnetic field in the space within and around the coil, where the crucible containing the metal is placed.

Step 3: Inducing Eddy Currents

According to Faraday's Law of Induction, a changing magnetic field will induce an electrical current in any conductor placed within it. The furnace's magnetic field penetrates the conductive metal charge, causing electrons within the metal to swirl in circular paths. These are the eddy currents.

Step 4: Resistive Heating (Joule Effect)

The induced eddy currents are not able to flow through the metal with perfect freedom. The metal has natural electrical resistance, which impedes the current flow. This opposition generates friction and creates intense heat, a principle known as Joule heating. This is what melts the metal.

Why "High Frequency" Matters

The choice of frequency is not arbitrary; it is a critical design parameter that fundamentally changes the furnace's behavior and applications.

Skin Effect and Heating Efficiency

Higher frequencies cause the induced eddy currents to concentrate near the surface of the metal charge. This phenomenon, known as the skin effect, allows for extremely rapid and efficient heating, as the thermal energy is generated in a concentrated outer layer.

The Inherent Stirring Action

The powerful magnetic fields and eddy currents create forces within the molten metal. This results in a natural, vigorous stirring action that ensures the melt is homogenous and promotes uniform alloy composition without mechanical intervention.

Coreless vs. Core-Type Furnaces

High-frequency furnaces are typically coreless, meaning the coil simply surrounds a non-conductive crucible holding the metal. In contrast, lower-frequency core-type or channel furnaces operate more like a traditional transformer, where an iron core links a primary coil to a loop of molten metal acting as the secondary coil.

Understanding the Trade-offs and Key Considerations

While powerful, induction heating is not a universal solution. Its effectiveness is governed by specific principles and requires careful engineering.

Material Must Be Conductive

The entire principle relies on inducing electrical currents within the charge. Therefore, induction furnaces can only directly heat materials that are electrically conductive, such as metals and graphite.

Coil Design is Critical

The efficiency of energy transfer depends heavily on the geometric relationship between the coil and the metal charge. The coil must be carefully designed for the specific size, shape, and type of material being melted.

A Key Application: The Vacuum Induction Furnace

One of the most valuable applications of this technology is in a vacuum induction furnace (VIM). By placing the entire coil and crucible assembly inside a vacuum chamber, the melting process can occur in a controlled atmosphere.

Achieving Unmatched Purity

The vacuum prevents the highly reactive molten metal from coming into contact with oxygen, nitrogen, and other atmospheric gases. This is essential for producing the high-purity superalloys used in critical applications like aerospace and medical implants.

How to Apply This to Your Goal

The specific type of induction furnace chosen is dictated entirely by the desired outcome.

- If your primary focus is rapid melting of various metals: A coreless high-frequency furnace provides the flexibility and speed needed for foundries that handle diverse alloys and charge sizes.

- If your primary focus is holding large volumes of a single molten metal: A lower-frequency channel or core-type furnace is often more energy-efficient for maintaining the temperature of a large bath for extended periods.

- If your primary focus is producing high-purity, reactive alloys: A vacuum induction furnace is non-negotiable, as it is the only way to prevent atmospheric contamination and achieve precise chemical control.

By transforming the material itself into the heater, induction technology offers a level of control and purity that is unmatched by conventional heating methods.

Summary Table:

| Principle | Function | Key Benefit |

|---|---|---|

| High-Frequency AC | Creates a rapidly changing magnetic field | Enables rapid surface heating (Skin Effect) |

| Eddy Currents | Induced electrical currents within the metal | Generates internal heat (Joule Effect) |

| Natural Stirring | Magnetic forces agitate the molten metal | Ensures a homogenous melt and uniform alloying |

| Vacuum Capability | Melting in a controlled atmosphere | Prevents contamination for high-purity alloys |

Ready to achieve rapid, precise, and pure metal melting in your lab or foundry?

KINTEK specializes in high-performance lab equipment, including induction furnaces tailored to your specific needs. Whether you require the flexibility of a coreless furnace for diverse alloys or the ultimate purity of a vacuum induction furnace for reactive metals, our experts can help you select the perfect solution.

Contact our team today to discuss how an induction furnace can enhance your process efficiency and product quality.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting