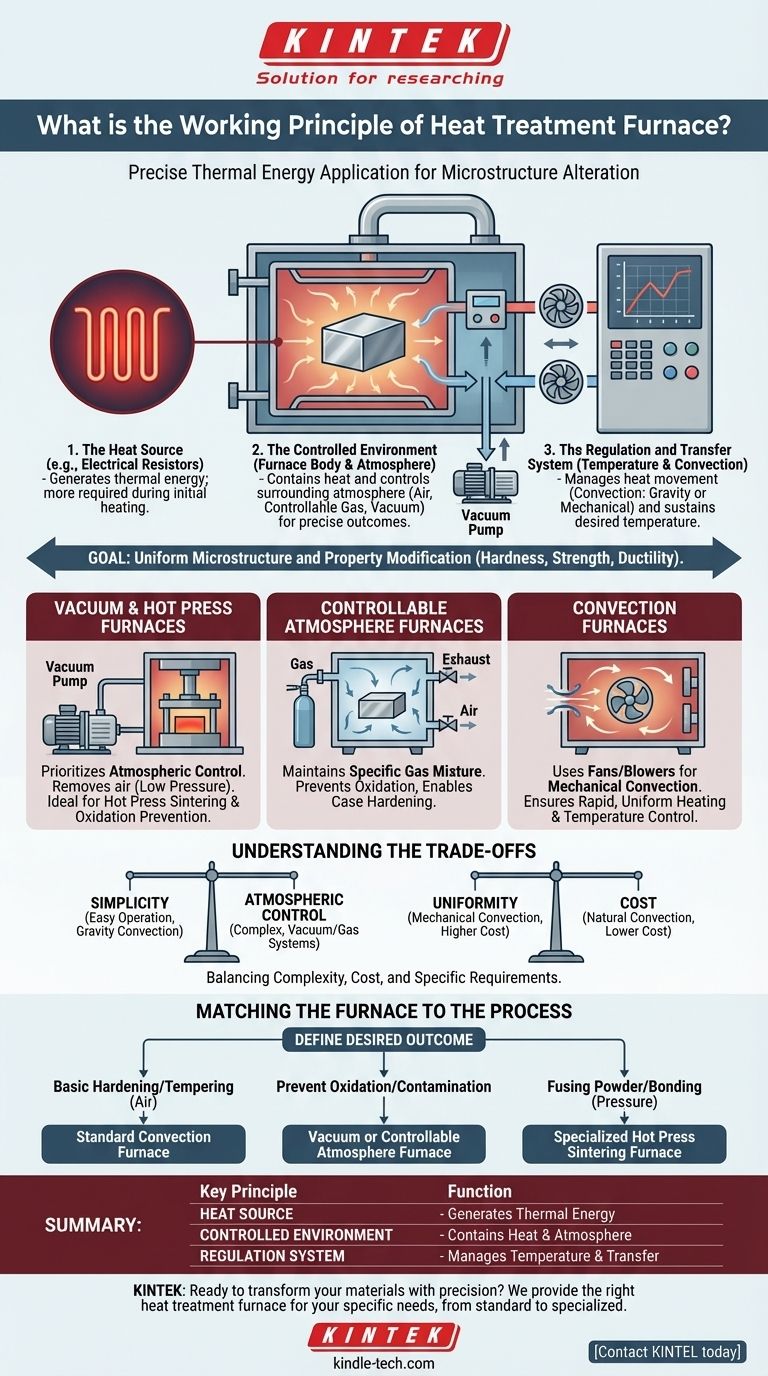

At its core, a heat treatment furnace works by using a controlled system to apply, hold, and remove thermal energy within a contained environment. This process is designed to precisely alter the internal microstructure of a material, thereby changing its physical and mechanical properties like hardness, strength, or ductility to meet a specific requirement.

The fundamental principle is not just about heating; it's about the precise control of three key elements: a heat source, a contained atmosphere (the furnace chamber), and a system for regulating temperature and heat transfer over time.

The Core Components of Operation

To understand how a heat treatment furnace functions, we can break it down into its three essential systems. Every furnace, from a simple laboratory model to a complex industrial unit, relies on these principles.

The Heat Source

The process begins with generating thermal energy. This is typically accomplished with heating elements, such as electrical resistors, that convert electricity into heat.

The amount of heat generated is not constant. More energy is required during the initial heating period to bring the material and the furnace chamber up to the target temperature.

The Controlled Environment

The material is placed inside a furnace body or chamber designed to contain the heat and control the surrounding atmosphere. This control is critical to the outcome.

The chamber can be a simple insulated box or a highly specialized vessel. For advanced processes, it must be well-sealed to manage the internal environment precisely.

This environment might be normal air, a specific mixture of gases (controllable atmosphere), or a near-total absence of air (vacuum).

The Regulation and Transfer System

This system manages how heat moves and maintains the desired temperature. Once the target temperature is reached, the system reduces the energy output to a constant level to sustain it.

Heat is transferred to the material through methods like convection. This can be gravity convection, where hot air naturally rises, or mechanical convection, which uses fans and blowers for faster, more even heating.

In some designs, an internal impeller agitates the gas within the chamber, forcing the convection of heat and ensuring the material is heated uniformly.

How Different Furnace Designs Apply These Principles

Different heat treatment goals require different types of furnaces, each emphasizing a specific aspect of control.

Vacuum and Hot Press Furnaces

These furnaces prioritize atmospheric control by first removing almost all air from the chamber. A vacuum system creates a low-pressure environment.

This is critical for processes like hot press sintering, where ceramic powder is heated and fused under high pressure without reacting with oxygen or other contaminants.

Controllable Atmosphere Furnaces

These furnaces use a sealed chamber, ventilation, and exhaust devices to maintain a specific gas mixture around the material.

The goal is to prevent undesirable reactions like oxidation or to intentionally introduce elements into the material's surface, a process known as case hardening.

Convection Furnaces

Many laboratory and industrial furnaces use fans, blowers, and baffles to actively circulate the heated air or gas.

This mechanical convection ensures the entire chamber and the material within it reach the target temperature quickly and, most importantly, uniformly.

Understanding the Trade-offs

Choosing or operating a furnace involves balancing complexity, cost, and the specific requirements of the heat treatment process.

Simplicity vs. Atmospheric Control

A simple laboratory furnace using gravity convection is easy to operate but offers no control over the atmosphere, making it unsuitable for materials sensitive to oxidation.

Conversely, a vacuum furnace provides the ultimate atmospheric control but requires complex vacuum pumps, seals, and operational procedures.

Uniformity vs. Cost

While natural convection works, it can lead to uneven heating. Adding blowers and baffles for mechanical convection dramatically improves temperature uniformity but adds to the furnace's initial cost and maintenance needs.

Process Specialization

Some furnaces are highly specialized. A hot press sintering furnace, for example, combines heat, vacuum, and a high-pressure system. This makes it incredibly effective for its specific task but not versatile for general-purpose heat treating.

Matching the Furnace to the Process

To select the right approach, you must first define the desired outcome for your material.

- If your primary focus is basic hardening or tempering in air: A standard furnace with mechanical convection provides the necessary temperature control and uniformity.

- If your primary focus is preventing surface oxidation or contamination: A vacuum or controllable atmosphere furnace is essential to protect the material.

- If your primary focus is fusing powdered materials or bonding composites: A specialized unit like a hot press sintering furnace that integrates pressure is required.

Ultimately, a heat treatment furnace is a precise tool for manipulating material properties through the controlled application of energy.

Summary Table:

| Key Principle | Function |

|---|---|

| Heat Source | Generates thermal energy (e.g., via electrical resistors). |

| Controlled Environment | Contains heat and manages the internal atmosphere (air, gas, vacuum). |

| Regulation System | Manages temperature and heat transfer for uniform, precise results. |

Ready to transform your materials with precision?

KINTEK specializes in laboratory equipment and consumables, providing the right heat treatment furnace for your specific needs—whether it's a standard model for hardening or a specialized vacuum furnace for sensitive materials. Our expertise ensures you get the perfect balance of performance, control, and cost-effectiveness for your lab.

Contact KINTEL today to discuss your application and find the ideal furnace solution!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What are the benefits of using HIP equipment for high-entropy alloys? Achieve Near-Theoretical Density & Durability

- What is the temperature range of arc heating? Unlock Extreme Heat for Industrial Applications

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- What are the two types of furnace technologies used in heat treatment? Atmosphere vs. Vacuum Explained

- What are the applications of vacuum furnace? Achieve Purity and Precision in High-Temperature Processing

- What role does a vacuum drying oven play in processing LLZTO-polymer slurries? Protect Purity and Material Integrity

- What is the process of arc melting? A Deep Dive into High-Temperature Metal Melting

- What temperature does a sealed quench furnace run at? A Guide to Optimizing Your Heat Treatment