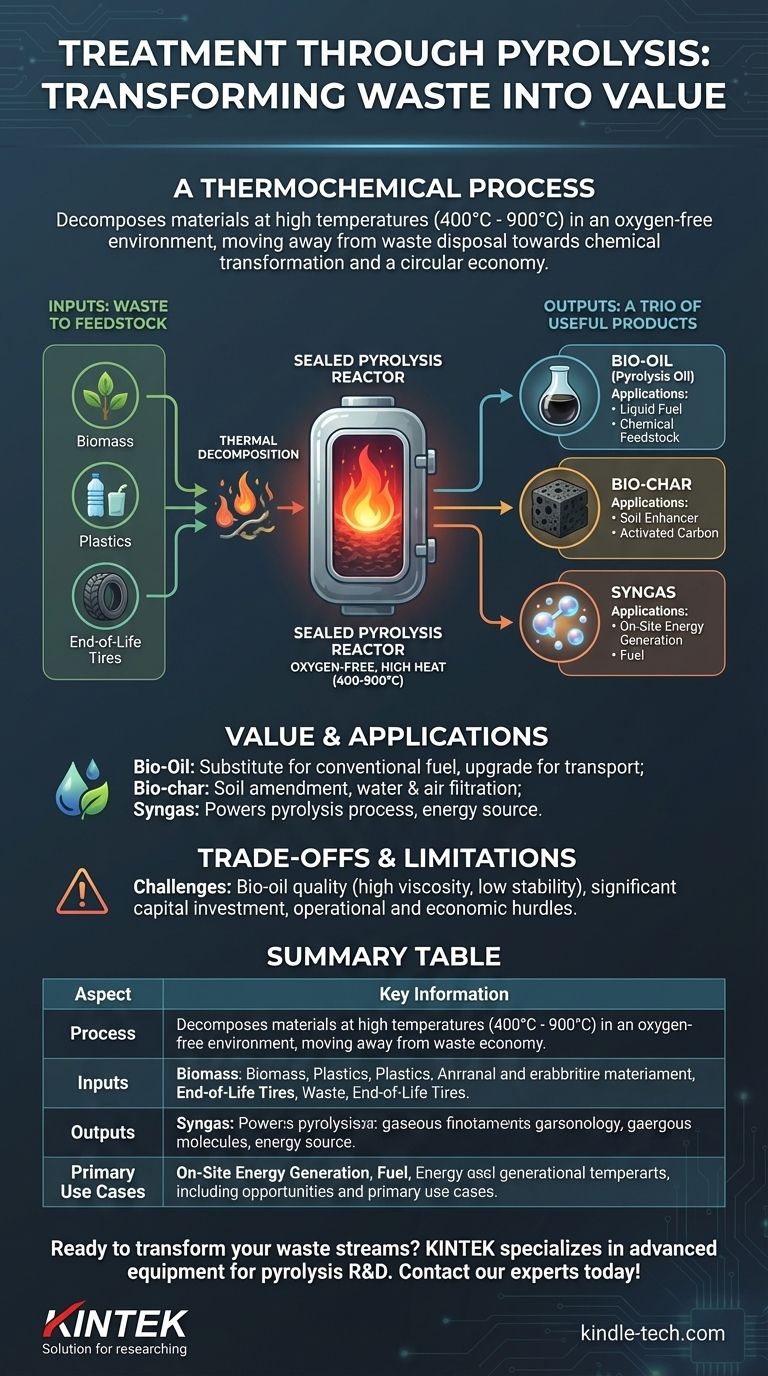

At its core, treatment through pyrolysis is a thermochemical process that decomposes materials at high temperatures in an oxygen-free environment. Instead of burning waste, this method breaks it down into a set of fundamentally different and valuable outputs: a liquid fuel known as bio-oil, a solid carbon-rich material called bio-char, and a combustible gas called syngas.

Pyrolysis is best understood not as waste disposal, but as a form of chemical transformation. It unlocks the value trapped within waste materials like biomass or plastics by converting them into useful energy and material feedstocks, moving us closer to a circular economy.

How Pyrolysis Works: A Controlled Transformation

Pyrolysis is distinct from incineration because it does not involve combustion. The absence of oxygen is the critical factor that forces a different chemical pathway, leading to decomposition rather than burning.

The Pyrolysis Reactor: An Oxygen-Free Environment

Materials are fed into a sealed reactor and heated to extreme temperatures, typically between 400°C and 900°C. The intense heat without oxygen breaks down the long, complex molecules of the input material into smaller, simpler ones.

This process, known as thermal decomposition, results in the creation of new substances with entirely different properties from the original waste.

The Inputs: From Waste to Feedstock

Pyrolysis is versatile and can process a wide range of organic and carbon-based materials that would otherwise end up in a landfill.

Common inputs include waste biomass (wood, agricultural residue), certain types of plastics, and end-of-life tires. The goal is to treat these materials as a resource, not as refuse.

The Outputs: A Trio of Useful Products

The process reliably separates the input material into three distinct product streams:

- Bio-oil (Pyrolysis Oil): A dark, viscous liquid that is the condensed form of the vaporized organic matter.

- Bio-char: A stable, solid, charcoal-like residue that is rich in carbon.

- Syngas (Synthesis Gas): A mixture of combustible gases (primarily hydrogen and carbon monoxide) that do not condense into a liquid.

The Value and Application of Pyrolysis Products

Each output from the pyrolysis process has specific applications, turning a waste stream into multiple revenue or resource streams. This versatility is the primary driver of its adoption.

Bio-Oil: A Liquid Fuel and Chemical Feedstock

Pyrolysis oil can be used directly as a substitute for conventional fuel oils in stationary applications like industrial boilers and power generation units.

It can also be upgraded within a refinery to produce more conventional hydrocarbon fuels or serve as a base feedstock for producing new chemicals and materials.

Bio-char: A Powerful Soil Enhancer

Bio-char is highly valued as a soil amendment. Its porous structure improves soil aeration and water retention, and it can help sequester carbon in the ground for long periods.

It also serves as a primary material for producing activated carbon, which is used extensively in water and air filtration systems to absorb pollutants.

Syngas: On-Site Energy Generation

The syngas produced is a valuable fuel in its own right. It is often captured and used to provide the energy needed to power the pyrolysis process itself, making the operation more self-sufficient and energy-efficient.

Understanding the Trade-offs and Limitations

While pyrolysis is a powerful technology, it is not without its challenges. Understanding its practical limitations is crucial for realistic implementation.

The Challenge of Pyrolysis Oil Quality

The direct industrial application of raw bio-oil can be limited. The oil often has high viscosity, low chemical stability, and can be corrosive to standard engines and pipelines.

For many high-value applications, such as transportation fuel, bio-oil requires significant and often costly post-processing or "upgrading" to meet quality standards like ASTM D7544.

Operational and Economic Hurdles

Scaling a pyrolysis plant requires significant capital investment in reactors, control systems, and safety equipment. The economic viability depends heavily on the cost of feedstock, the market value of the end products, and efficient, continuous operation.

Furthermore, ensuring the overall process is truly sustainable—from sourcing feedstock to managing outputs—remains a key consideration for large-scale industrial use.

Making the Right Choice for Your Goal

Pyrolysis is not a single-purpose solution but a versatile platform. Your primary objective will determine how you leverage the technology.

- If your primary focus is sustainable waste management: Pyrolysis offers a powerful method to divert waste from landfills and convert it into marketable commodities, directly supporting circular economy principles.

- If your primary focus is renewable energy production: The syngas and bio-oil serve as valuable energy sources that can reduce reliance on fossil fuels, though the oil may require upgrading for certain applications.

- If your primary focus is agricultural improvement and carbon sequestration: The bio-char created is a stable, high-value product that can enhance soil health and lock away carbon for decades.

Ultimately, pyrolysis provides a sophisticated toolkit for transforming low-value materials into high-value resources.

Summary Table:

| Aspect | Key Information |

|---|---|

| Process | Thermal decomposition at 400-900°C without oxygen |

| Inputs | Biomass, plastics, tires |

| Outputs | Bio-oil (fuel), bio-char (soil enhancer), syngas (energy) |

| Primary Use Cases | Waste management, renewable energy, agriculture |

Ready to transform your waste streams into valuable resources? KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and development. Whether you're exploring sustainable waste management, renewable energy production, or agricultural enhancement, our precision tools help you optimize your pyrolysis processes. Contact our experts today to discover how KINTEK can support your laboratory's journey toward a circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process